Separately excited DC motor soft starter based on XE164FN

A technology of XE164FN and DC motor, which is applied in the direction of single DC motor starter, motor generator/starter, AC motor deceleration device, etc., which can solve the problem of power supply voltage drop, abnormal wear of mechanical transmission parts, accelerated equipment aging, etc. problem, to achieve the effects of small inrush current and inrush torque, easy failure and maintenance, and personal safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

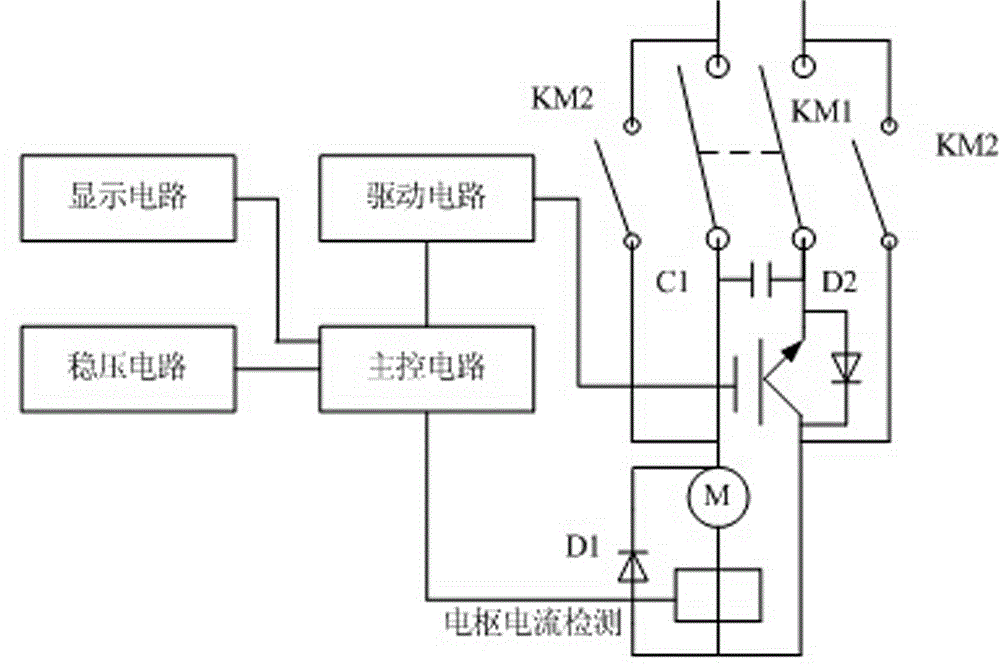

[0017] combine figure 1 , figure 1 It is the hardware block diagram of the soft starter. The system mainly includes hardware and software. The hardware circuit is the main control circuit, including the main circuit and the control circuit. The main circuit uses IGBT as the core, and the PWM DC chopper circuit. Receive the PWM pulse signal, make the IGBT turn on and off intermittently, change the duty ratio of the PWM signal, control the average value of the voltage applied to both ends of the armature winding of the DC motor, and control the soft start of the motor. The control circuit includes a display circuit, Regulator circuit.

[0018] The control circuit uses a single-chip microcomputer as the control core, and a port of the single-chip microcomputer outputs a PWM signal to drive the IGBT through the drive circuit. When calculating the maximum value, the microcontroller sends a signal to disconnect the voltage at both ends of the DC motor.

[0019] The display circu...

Embodiment 2

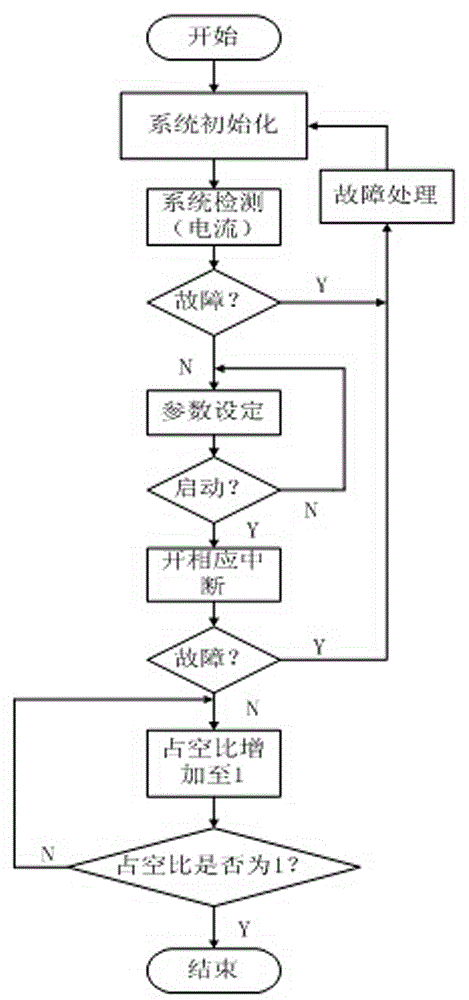

[0033] combine figure 2 , figure 2 It is the main program flow chart of the system. The system starts to run. First, the system is initialized. The initialization includes the initialization of the display module, AD module, timer and PCA (PWM pulse generation module). After the system is initialized, the armature current must be detected, and the armature current exceeding 1.5 times the rated current cannot be allowed to be generated in the motor. After the current detection, if there is a fault, perform fault handling until the fault is eliminated, then set and run the system parameters, and then turn on the interrupt, then perform current detection, and eliminate the fault when a fault occurs, and finally the duty cycle reaches 1, The startup is over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com