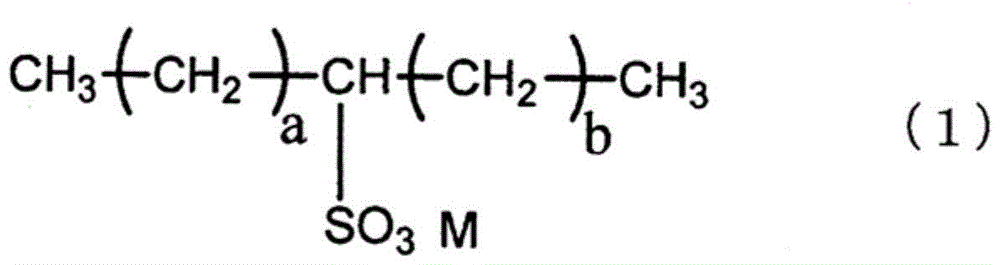

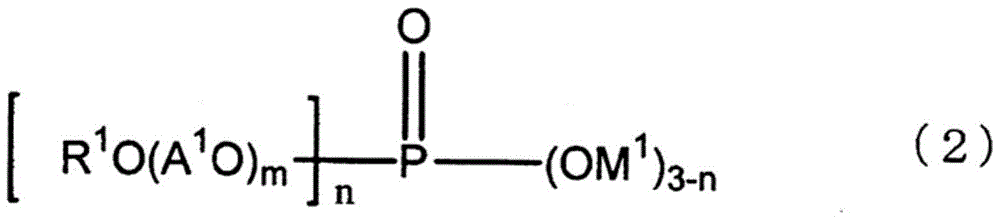

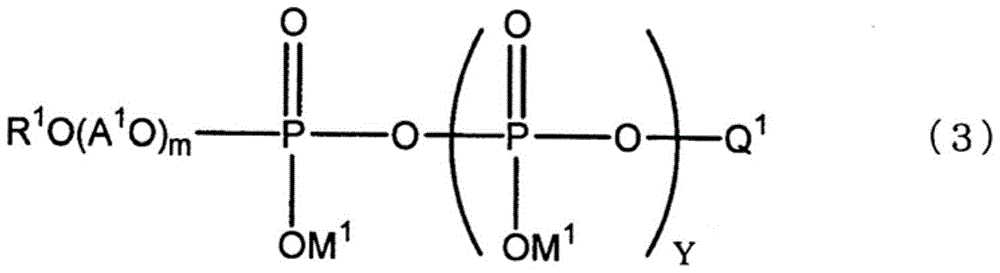

Treatment Agent for Synthetic Fiber and Its Utilization

A technology for synthetic fibers and synthetic fiber filaments, used in fiber treatment, chemical-change-inhibiting compositions, textiles, and papermaking, etc. problem, to achieve the effect of excellent heat resistance, reduced roller contamination, and reduced cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11、 comparative example 1~9

[0230] The components described in Tables 2 and 3 were mixed and stirred until uniform to prepare a treatment agent. Using each of the prepared treatment agents, the following methods were used to evaluate the contamination accumulation of the pin, the contamination wiping property of the pin, and the tension fluctuation. The results are shown in Tables 2 and 3.

[0231] In addition, the figure of the non-volatile composition of the processing agent of Table 2, 3 represents the weight ratio of each component (raw material X, Y, Z, these non-volatile components) in the non-volatile content of a processing agent. In addition, the details of the processing agent components of Tables 2 and 3 are shown in Table 1.

[0232] (Sulfate ion (SO 4 2- ), chloride ion (Cl - ), phosphate ion (PO 4 3- ) Determination method)

[0233] Accurately weigh 5 g of the sample (the non-volatile components of the treatment agent or the non-volatile components of raw materials X, Y, and Z), add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com