Preparation method of metal palladium loaded type SiO2 composite membrane

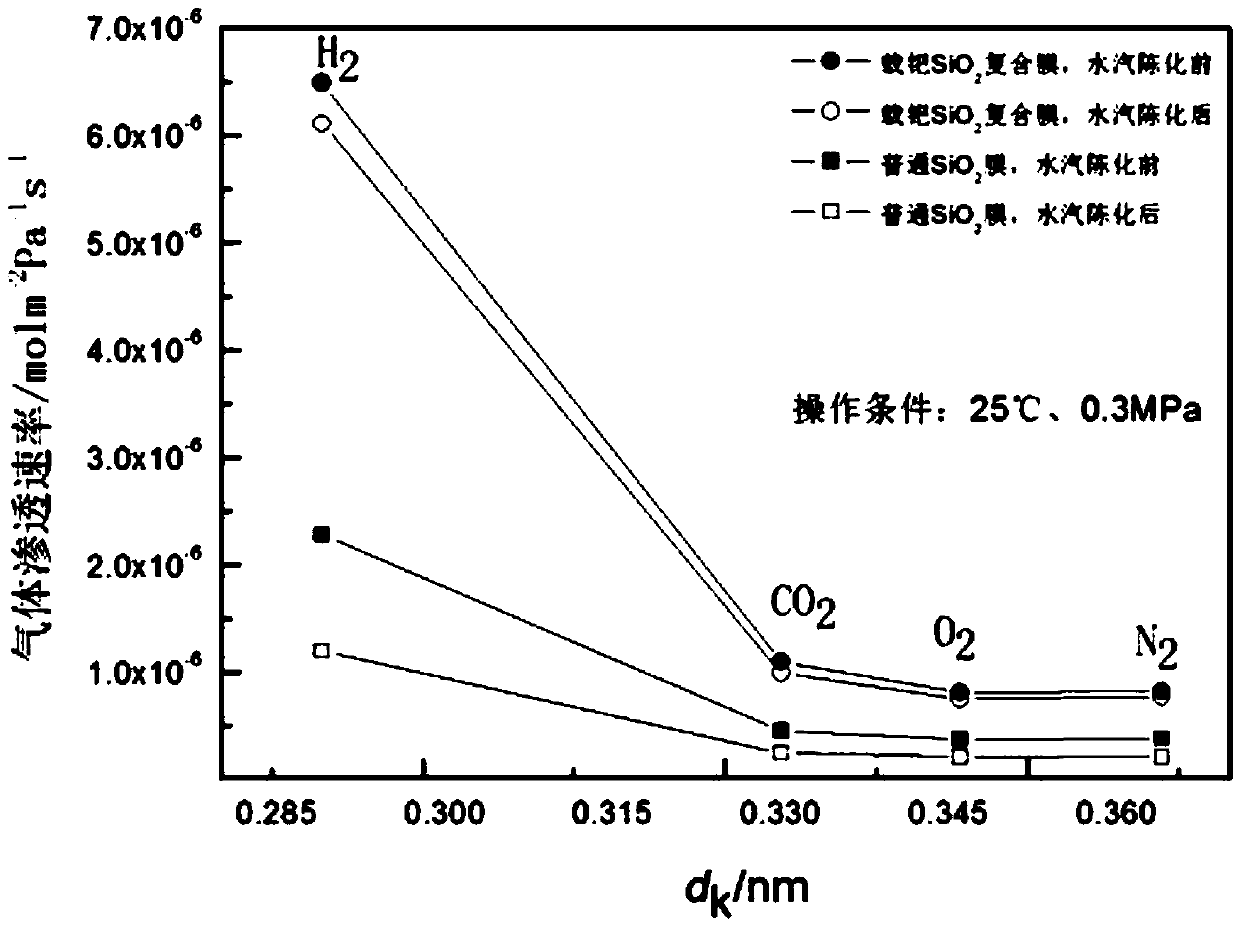

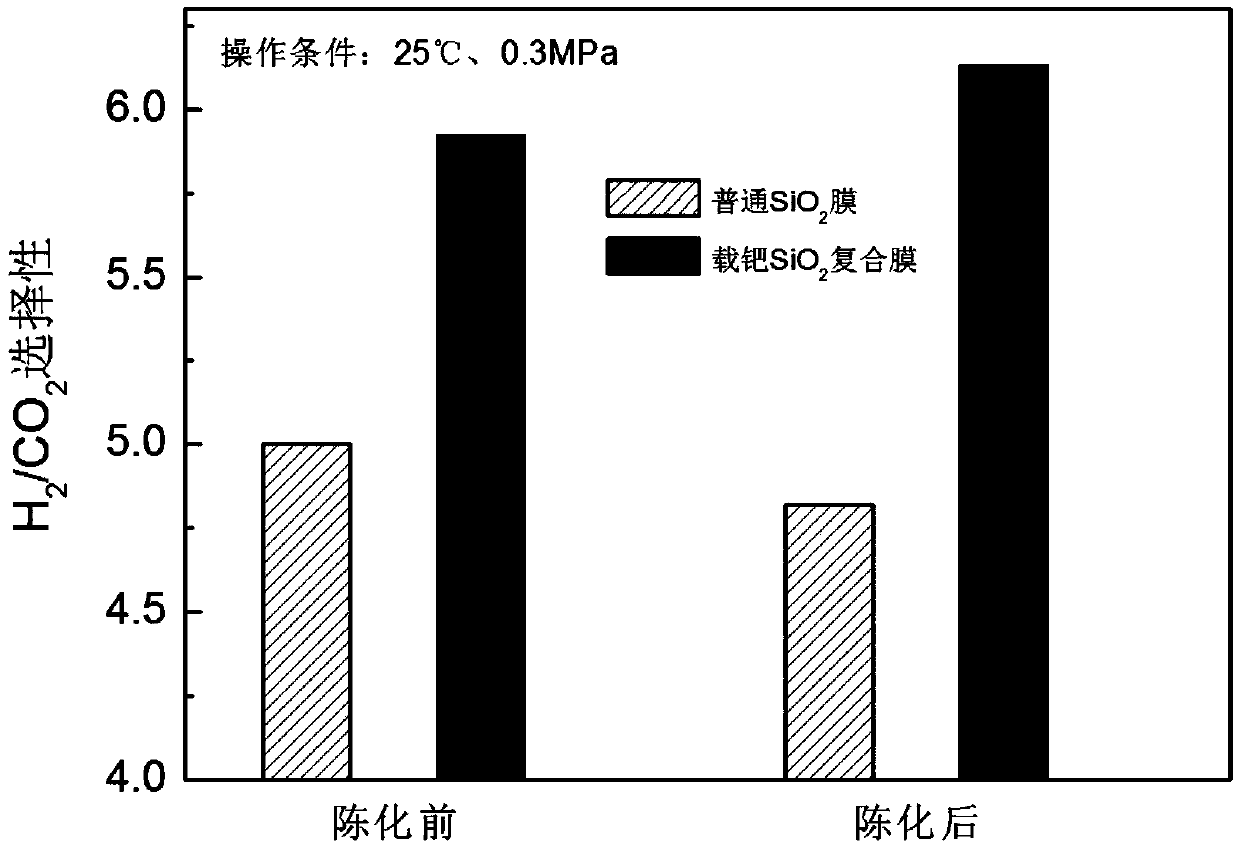

A supported, composite membrane technology, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of difficulty in increasing gas permeation rate and separation factor at the same time, so as to improve water vapor stability, improve separation selectivity, The effect of increasing the penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, fully mix ethyl orthosilicate, methyltriethoxysilane and absolute ethanol to form a homogeneous solution, place it in an ice-water mixture, add water and HCl with a concentration of 1.0mol / L while stirring The mixture was stirred and refluxed at 60 °C for 3 h and then cooled to obtain methylated SiO 2 Sol; wherein the molar ratio of ethyl orthosilicate (TEOS), methyltriethoxysilane (MTES), absolute ethanol (EtOH), water, and HCl is 1:0.81:7.7:7.3:0.086;

[0031] Step 2, to the methylation modified SiO obtained in step 1 2 Add N,N-dimethylformamide (the addition amount of N,N-dimethylformamide is methylated modified SiO 2 30% of the volume of the sol), stirred vigorously for 45min, and then pressed PdCl 2 The molar ratio to tetraethyl orthosilicate is 0.08:1, while stirring, add PdCl with a concentration of 0.14mol / L 2 solution and a mixture of absolute ethanol (N,N-dimethylformamide, PdCl 2 The sum of the volumes of the solution and absolute ethanol is methy...

Embodiment 2

[0035] Step 1, thoroughly mix ethyl orthosilicate, methyltriethoxysilane and absolute ethanol to form a homogeneous solution, place it in an ice-water mixture, add water and HCl with a concentration of 1.5mol / L while stirring The mixture was stirred and refluxed at 65 °C for 2.5 h and then cooled to obtain methylated SiO 2 Sol; wherein the molar ratio of ethyl orthosilicate (TEOS), methyltriethoxysilane (MTES), absolute ethanol (EtOH), water, and HCl is 1:0.9:8.3:7.6:0.10;

[0036] Step 2, to the methylation modified SiO obtained in step 1 2 Add N,N-dimethylformamide (the addition amount of N,N-dimethylformamide is methylated modified SiO 2 35% of the volume of the sol), stirred vigorously for 50min, and then pressed PdCl 2 The molar ratio to tetraethyl orthosilicate is 0.065:1, while stirring, add PdCl with a concentration of 0.14mol / L 2 solution and a mixture of absolute ethanol (N,N-dimethylformamide, PdCl 2 The sum of the volumes of the solution and absolute ethanol is...

Embodiment 3

[0040] Step 1, thoroughly mix ethyl orthosilicate, methyltriethoxysilane and absolute ethanol to form a homogeneous solution, place it in an ice-water mixture, add water and HCl with a concentration of 2.0mol / L while stirring The mixture was stirred and refluxed at 70 °C for 2 h and then cooled to obtain methylated SiO 2 Sol; wherein the molar ratio of ethyl orthosilicate (TEOS), methyltriethoxysilane (MTES), absolute ethanol (EtOH), water, and HCl is 1:1.0:9.0:8.0:0.12;

[0041] Step 2, to the methylation modified SiO obtained in step 1 2 Add N,N-dimethylformamide (the addition amount of N,N-dimethylformamide is methylated modified SiO 2 40% of the volume of the sol), stirred vigorously for 60min, and then pressed PdCl 2 The molar ratio to tetraethyl orthosilicate is 0.05:1, while stirring, add PdCl with a concentration of 0.14mol / L 2 solution and a mixture of absolute ethanol (N,N-dimethylformamide, PdCl 2 The sum of the volumes of the solution and absolute ethanol is me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com