Preparation method of strengthened type oil absorption cotton

An oil-absorbing cotton and reinforced technology is applied in the field of preparation of reinforced oil-absorbing cotton, which can solve the problems of not easy to salvage in water, low strength of oil-absorbing cotton, easy delamination, etc., and achieve the effects of large oil absorption, increased strength, and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

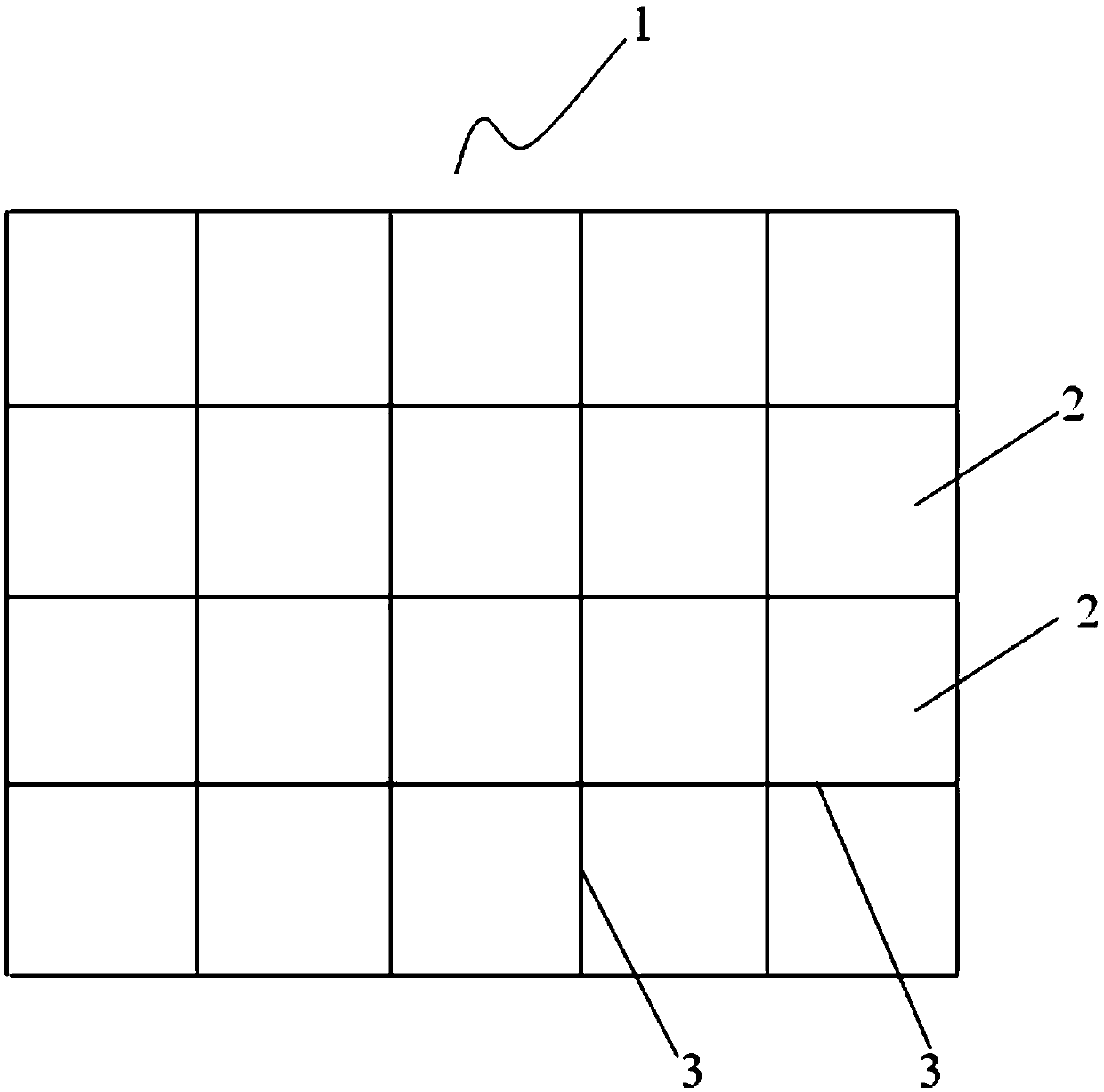

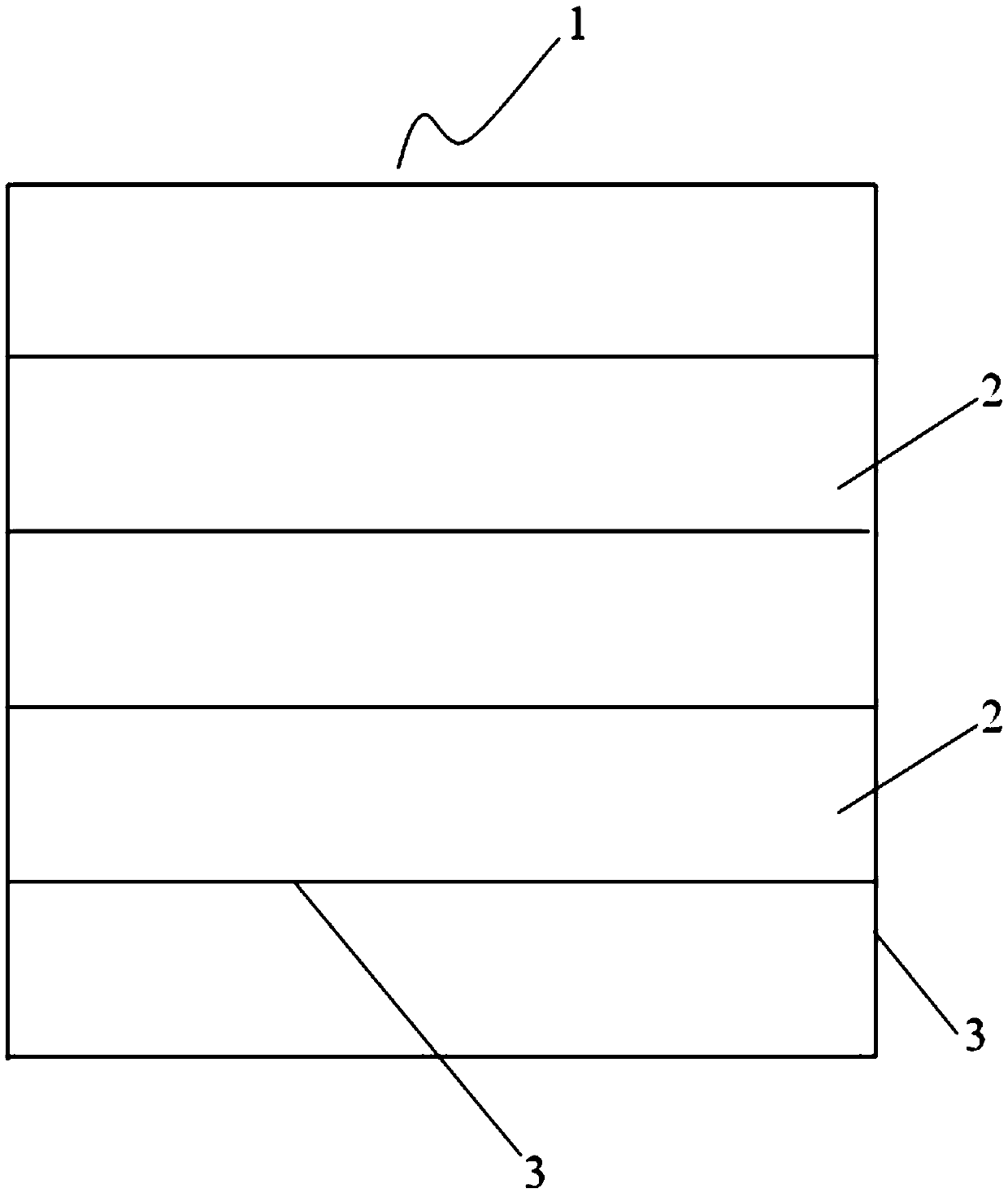

[0021] The invention discloses a preparation method of reinforced oil-absorbing cotton, which comprises the following steps: raw material preparation, melt extrusion, spinning into a net, strengthening into cloth, and eagerly cutting and winding, and also includes sewing up the eagerly cut oil-absorbing cotton 1 , the size of the eagerly cut oil-absorbing cotton 1 is 40cmx50cm, and the stitching process is wired stitching using a mechanical quilting process, and the stitching thread 3 used is a glass fiber yarn, and the diameter of the yarn is 0.8mm. First suture around the oil-absorbing cotton 1, and then suture the surface of the oil-absorbing cotton 1 horizontally and vertically, and the sewing track of the suture line 3 is linear, as shown in figure 1 As shown, the sutures 3 make the surface of the oil-absorbing cotton 1 form several evenly distributed oil-absorbing units 2, the shape of the oil-absorbing units 2 is rectangular, the size is 10cmx10cm, and the sutures 3 dist...

Embodiment 2

[0024] The invention discloses a preparation method of reinforced oil-absorbing cotton, which comprises the following steps: raw material preparation, melt extrusion, spinning into a net, strengthening into cloth, and eagerly cutting and winding, and also includes sewing up the eagerly cut oil-absorbing cotton 1 , the size of the eagerly cut oil-absorbing cotton 1 is 50cmx50cm, and the stitching process is wired stitching that adopts manual sewing, and the stitching thread 3 used is carbon fiber yarn, and the diameter of the yarn is 1.8mm. 1, and then transversely suture the surface of the oil-absorbing cotton 1, the suture track of the suture line 3 is straight, as figure 1 As shown, the sutures 3 make the surface of the oil-absorbing cotton 1 form several evenly distributed oil-absorbing units 2, the shape of the oil-absorbing units 2 is rectangular, the size is 10cmx50cm, and the number of sutures 3 distributed horizontally is 6. The length is 50cm, the vertically distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com