Method and system for producing refined sintered iron powder and refined pelletized iron powder simultaneously

A technology for iron powder and pellets, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of inflexible adjustment of product design, avoid the decline of equipment utilization efficiency, reduce construction investment, and give full play to equipment. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

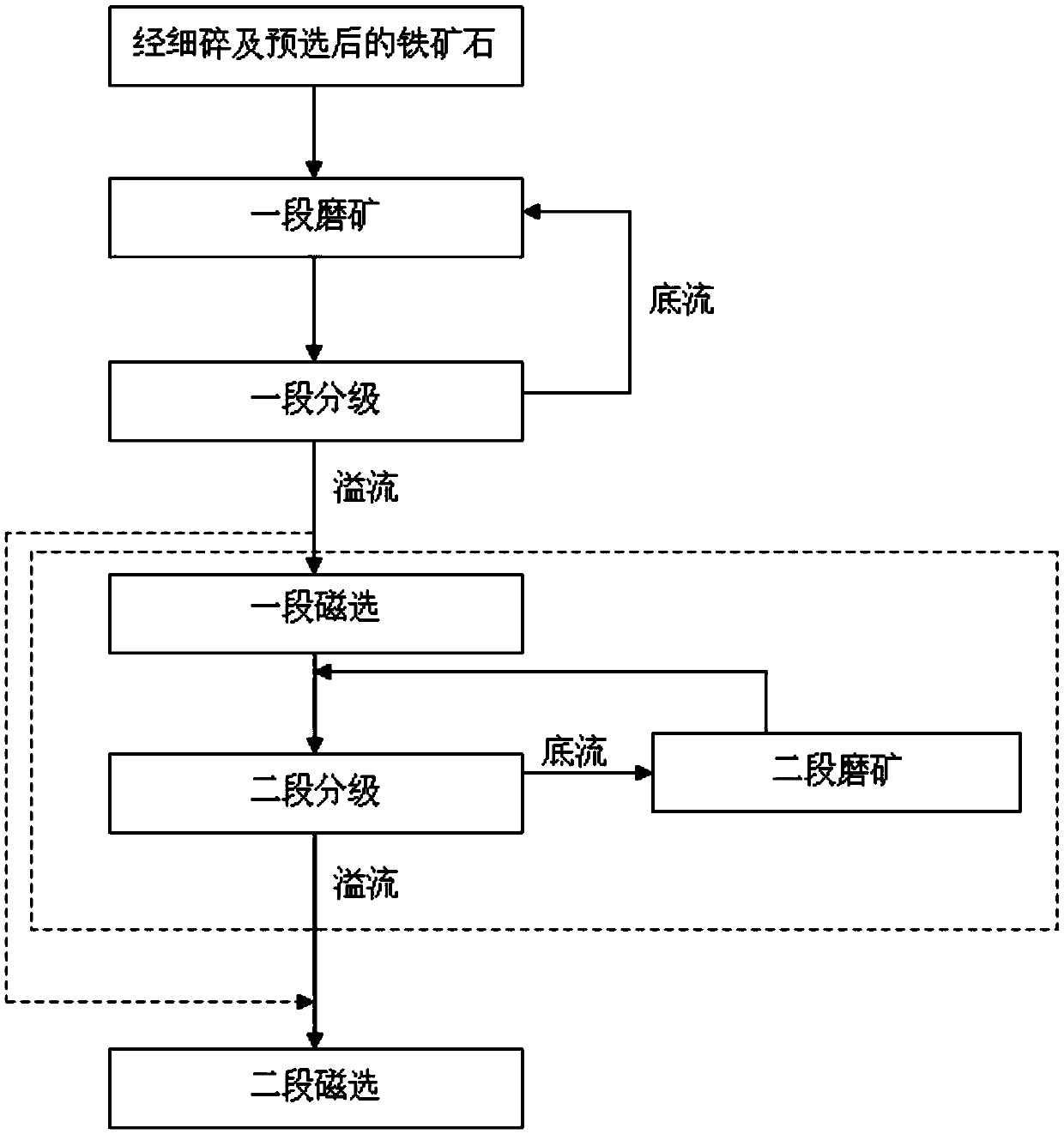

[0037] Such as figure 1 As shown, on the one hand, the embodiment of the present application provides a method for simultaneously producing sintered iron fine powder and pelletized iron fine powder, including:

[0038] Step S1: performing one-stage grinding on the finely crushed and pre-selected iron ore to obtain a one-stage grinding product;

[0039] Step S2: classify a section of grinding products to obtain a section of overflow mineral products and a section of underflow mineral products;

[0040] Step S3.1: The first-stage overflow mineral product is subjected to second-stage magnetic separation to obtain sintered iron concentrate, and the first-stage underflow mineral product is returned to the ball mill for first-stage grinding;

[0041] Or, step S3.2: After the first-stage overflow mineral product is subjected to the first-stage magnetic separation, the second-stage grinding and the second-stage classification, then the second-stage magnetic separation is performed to...

Embodiment 2

[0052] A newly-built large-scale iron ore dressing plant, the designed dressing process is coarse crushing-secondary crushing-closed-circuit screening-high-pressure roller mill-coarse wet pre-selection-one-stage closed-circuit grinding-one-stage magnetic separation-second-stage closed-circuit grinding-two Segmental magnetic separation-flotation, producing pellets with a particle size of -325 mesh accounting for 80%.

[0053] In this process, the ore has a particle size of 0-3mm after high-pressure roller milling and coarse wet pre-selection. The separation process of stage grinding stage is one stage of closed circuit grinding - one stage of magnetic separation - two stage of closed circuit grinding - two stage of magnetic separation.

[0054] When the grinding particle size of the iron ore processed by the concentrator is -200 mesh 65%, the iron grade of the iron concentrate produced can reach more than 65%, but it still contains a certain amount of other impurities. If the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com