A kind of collector for sorting lead ore and preparation method thereof

A collector and lead separation technology, which is applied in flotation, solid separation, etc., can solve the problems of easy mudification of oxidized lead ore, complicated conventional process, and low grade of concentrate, and achieve low foaming strength and high mineral processing technology. The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

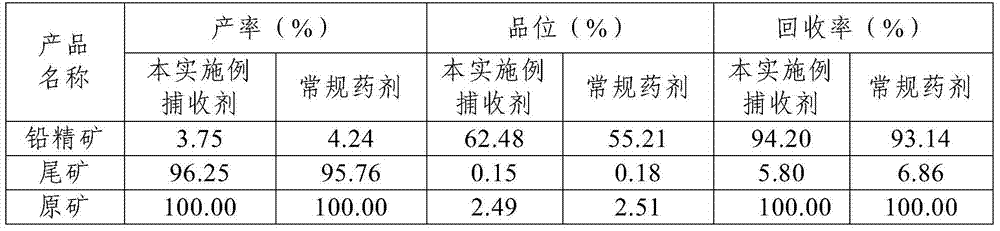

Embodiment 1

[0026] The collector of the present embodiment is made from the following raw materials: 80g of pentaerythritol, 20g of carbon disulfide, 50g of monochloroacetic acid, 65g of n-butylamine aqueous solution, 120g of pentaerythritol, 100g of terpineol oil, 40g of caustic soda, 60g of sodium sulfide, mass Concentration is 8% water glass solution 100g, diesel oil 20g, reduced nickel powder 5g; The volume percent concentration of n-butylamine in the n-butylamine aqueous solution is 65%.

[0027] The preparation method of the collector of the present embodiment may further comprise the steps:

[0028] Step 1. Mix pentapentylpentyl alcohol, carbon disulfide and 20g caustic soda evenly, reflux the mixed mixture at 75°C for 25min, then add monochloroacetic acid and n-butylamine aqueous solution to the refluxed mixture, and reflux at 35°C Down stirring reaction 2h, obtain oily material;

[0029] Step 2. Put pentaerythritol, pine alcohol oil, diesel oil, active nickel catalyst and the re...

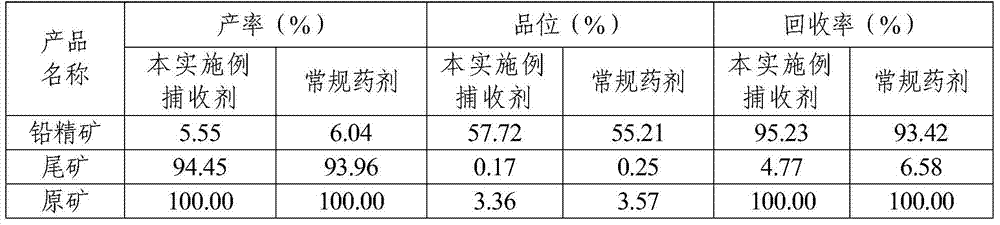

Embodiment 2

[0043] The collector of the present embodiment is made of the following raw materials: 70g of pentaerythritol, 25g of carbon disulfide, 40g of monochloroacetic acid, 60g of n-butylamine aqueous solution, 100g of pentaerythritol, 80g of terpineol oil, 50g of caustic soda, 50g of sodium sulfide, mass Concentration is 10% water glass solution 80g, diesel oil 25g, Raney nickel 3g; The volume percent concentration of n-butylamine in the n-butylamine aqueous solution is 50%.

[0044] The preparation method of the collector of the present embodiment may further comprise the steps:

[0045] Step 1. Mix pentapentylpentyl alcohol, carbon disulfide and 20g of caustic soda evenly, and reflux the mixed mixture at 80°C for 20min, then add monochloroacetic acid and n-butylamine aqueous solution to the refluxed mixture, and heat it at 40°C Under stirring reaction 1.5h, obtain oily material;

[0046] Step 2. Put pentaerythritol, terpineol oil, diesel oil, active nickel catalyst and the remain...

Embodiment 3

[0059] The collector of the present embodiment is made of the following raw materials: 100g of pentaerythritol, 15g of carbon disulfide, 60g of monochloroacetic acid, 70g of n-butylamine aqueous solution, 150g of pentaerythritol, 120g of terpineol oil, 30g of caustic soda, 70g of sodium sulfide, mass Concentration is 5% water glass solution 120g, diesel oil 15g, reduced nickel powder 7g; The volume percent concentration of n-butylamine in the n-butylamine aqueous solution is 70%.

[0060] The preparation method of the collector of the present embodiment may further comprise the steps:

[0061] Step 1. Mix pentapentylpentyl alcohol, carbon disulfide and 9g of caustic soda evenly, and reflux the mixed mixture at 70°C for 30 minutes, then add monochloroacetic acid and n-butylamine aqueous solution to the refluxed mixture, and reflux at 30°C Under stirring reaction 3h, obtain oily material;

[0062] Step 2. Put pentaerythritol, pine alcohol oil, diesel oil, active nickel catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com