Electrostatic precipitation circulating type water film dust removing device and method

A technology of dust collecting device and circulating water, applied in the field of water film dust collecting device and corona dust collecting water film dust collecting device, can solve the problems of accumulation of dust on electrostatic field plate, decrease of dust removal effect, secondary pollution of dust, etc., to achieve dust removal. High efficiency, simple structure and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

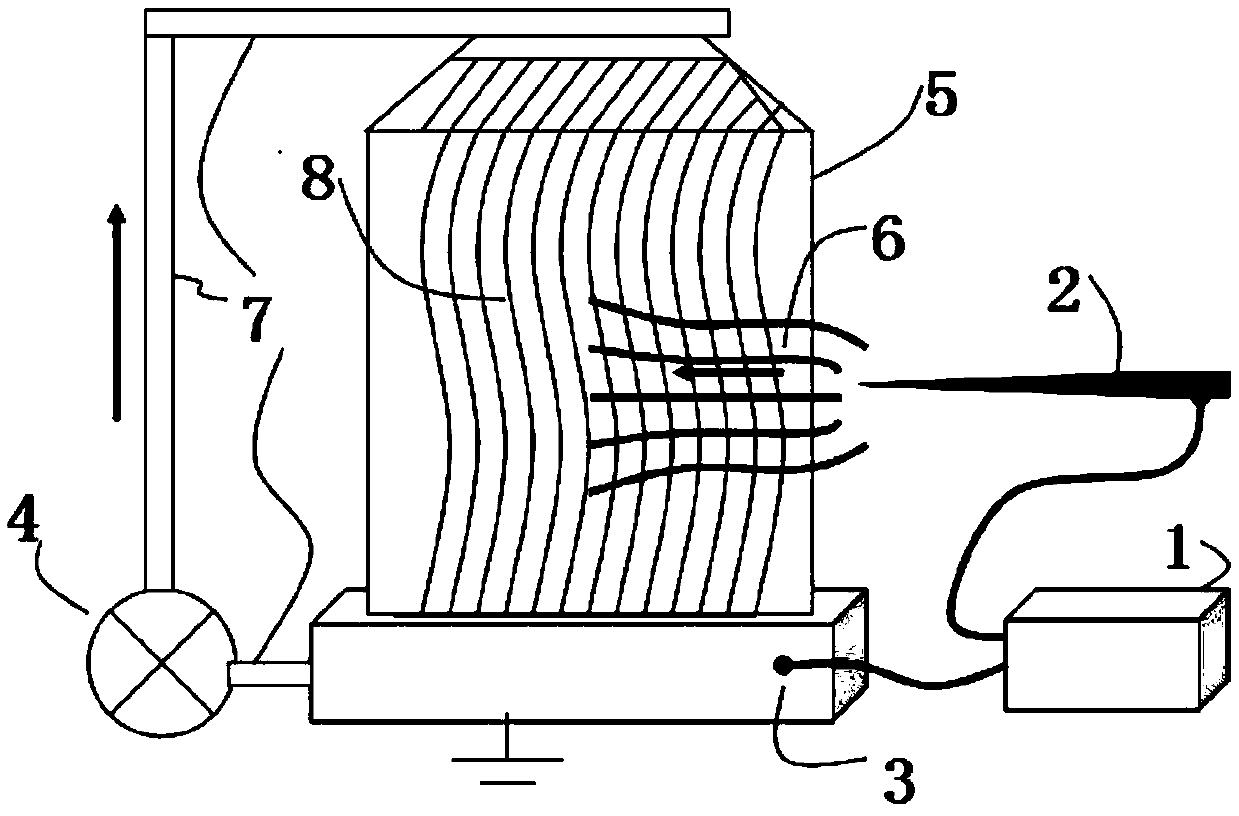

[0022] Such as figure 1 As shown, the water pump 4 in the circulating water system pushes the water in the water pipe 7 to flow in the water pipe 7 . Water flows on the water guide plate 5 from the upper end of the water guide plate 5, forms a water film 8 on the water guide plate 5, and the water of the water film 8 gathers downwards in the water tank at the lower end of the water guide plate. During the continuous circulation of the water flow, there is a circulating water film 8 on the water guide plate 7 .

[0023] A negative electrode needle 2 perpendicular to the water film 8 is provided at a distance from the water film 8 . The entire circulating water system is connected to the earth and has the same potential as the earth. The positive pole of the high-voltage power supply is connected with the positive electrode 3 in the water tank. The negative pole of the high-voltage power supply 1 is connected to the negative pole electric needle 2 .

[0024] Under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com