Oil tank and sewage tank mechanical automatic cleaning and recovery system and method

A technology of automatic cleaning and recycling methods, applied in cleaning methods and utensils, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of many preparations, slow cleaning speed, and incomplete cleaning. , to achieve the effect of improving work efficiency, strong work ability and significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The mechanical automatic cleaning and recovery method of the sewage tank of the oil storage tank of the present invention, through the following steps:

[0021] a. Oil transfer: transfer the liquid crude oil in the tank to be cleaned out of the tank to be cleaned;

[0022] b. Mechanical ventilation: the oil vapor in the tank to be cleaned is completely discharged by injecting nitrogen;

[0023] c. Cleaning of the same oil: heat the tank to be cleaned to 70°C, pressurize the crude oil in other tanks to 0.9MPa, crush and dissolve the condensed oil in various parts of the tank to be cleaned, and disperse it , After it has fluidity, it is transferred out of the tank to be cleaned;

[0024] d. Washing with warm water: After pressurizing clean water at 80°C to 0.6 MPa, clean all parts in the tank; discharge the oil-water mixture after cleaning;

[0025] e. Separation. After the oil-water mixture discharged in step d is fully stirred and air-floated, the three-phase separati...

Embodiment 2

[0027] The mechanical automatic cleaning and recovery method of the sewage tank of the oil storage tank of the present invention, through the following steps:

[0028] a. Oil transfer: transfer the liquid crude oil in the tank to be cleaned out of the tank to be cleaned;

[0029] b. Mechanical ventilation: the oil vapor in the tank to be cleaned is completely discharged by injecting nitrogen;

[0030] c. Cleaning of the same oil: heat the tank to be cleaned to 90°C, pressurize the crude oil in other tanks to 0.6MPa, crush and dissolve the condensed oil in various parts of the tank to be cleaned, and disperse it , After it has fluidity, it is transferred out of the tank to be cleaned;

[0031] d. Washing with warm water: After pressurizing clean water at 100°C to 0.9MPa, clean all parts in the tank; discharge the oil-water mixture after cleaning;

[0032] e. Separation. After the oil-water mixture discharged in step d is fully stirred and air-floated, the three-phase separati...

Embodiment 3

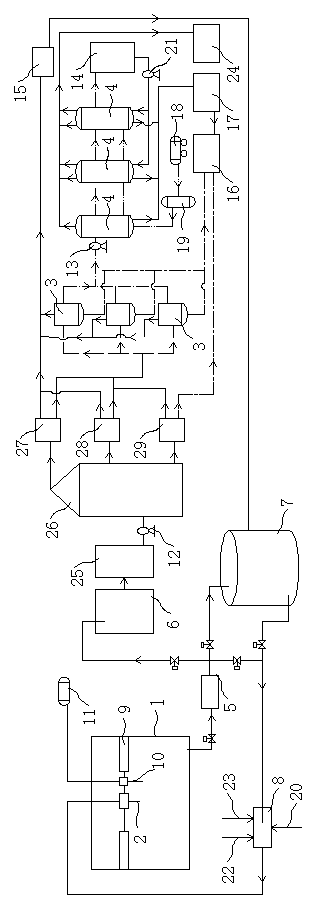

[0035] The mechanical automatic cleaning and recovery system of the sewage tank of the oil storage tank of the present invention is composed of a tank body 1, a cleaning spray gun 2, a coagulation settling tank 3 and a muddy water settling tank 4. The bottom outlet pipeline of the tank body 1 is connected to the suction The device 5 is connected, the outlet of the suction device 5 is respectively connected with the buffer pool 6, the inlet of the oil tank 7 and the outlet pipeline of the oil tank 7, and the outlet pipeline of the oil tank 7 is connected with the circulation device 8 and the floating boat in the inner cavity of the tank body 1 in turn. More than one cleaning spray gun 2 in the lower part of 9 is connected, and a nitrogen inlet 10 is provided on the floating boat 9 to communicate with the external nitrogen tank 11; Tower 26; the top pipeline outlet of the trinity separation tower 26 communicates with the secondary separation tank I 27, the upper pipeline outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com