Casting shakeout machine

A technology of a shakeout machine and a shakeout device, which is applied in the foundry field, can solve the problems of workers' health injury, high temperature of sand and dust particles, and increased labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

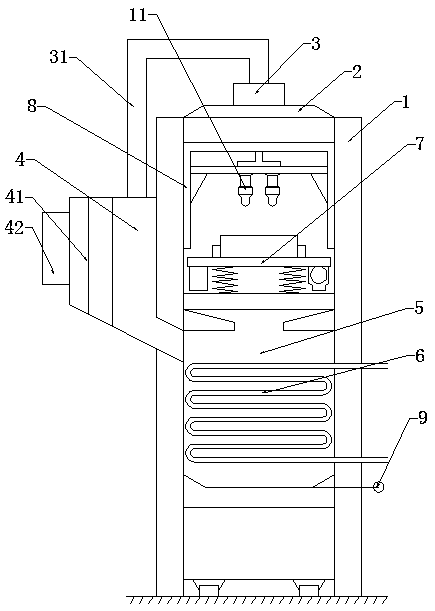

[0013] The reference signs in the drawings of the description include: frame 1, wind collecting hood 2, exhaust fan 3, filter box 4, filter screen 41, exhaust fan 42, sand collection box 5, cooling pipe 6, vibrating seat 7, sound-absorbing layer 8 , gate 9.

[0014] The embodiment is basically as attached figure 1 Shown: a foundry shakeout machine, including a frame 1, a shakeout device, a sand collection device and a noise reduction and dust removal device. The frame 1 is a vertical rectangular box, and the sand shakeout device is installed on the upper end inside the frame 1, and the sand shakeout device includes a hammer and a vibration seat 7 located below the hammer. The sand collection device is installed under the vibration seat 7, and the sand collection device includes a sand collection box 5, the upper and lower ends of the sand collection box 5 are funnel-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com