Four-freedom-degree 3SPRR and SP type hybrid flexible hands for robots

A technology of robot and degree of freedom, which is applied in the field of robot to achieve the effect of less degree of freedom, simple structure and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

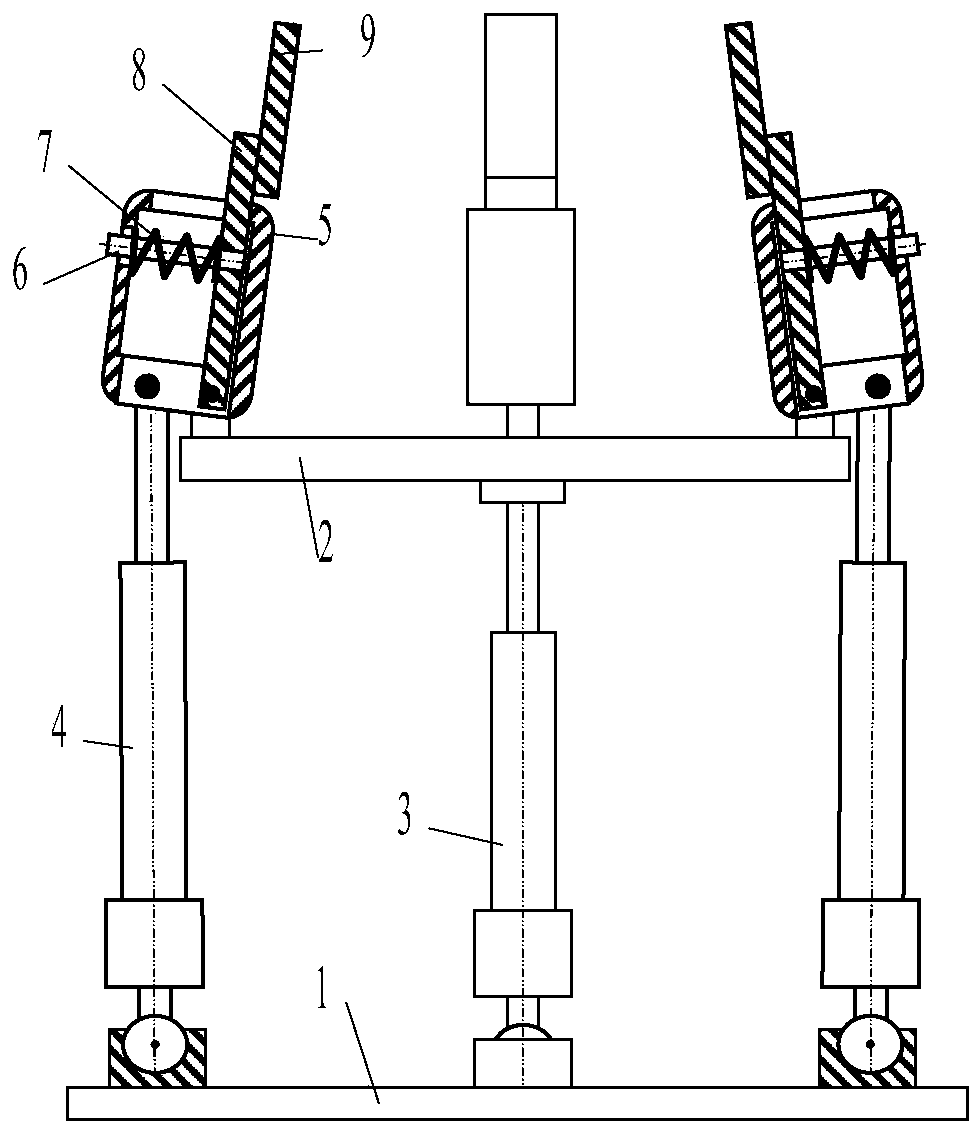

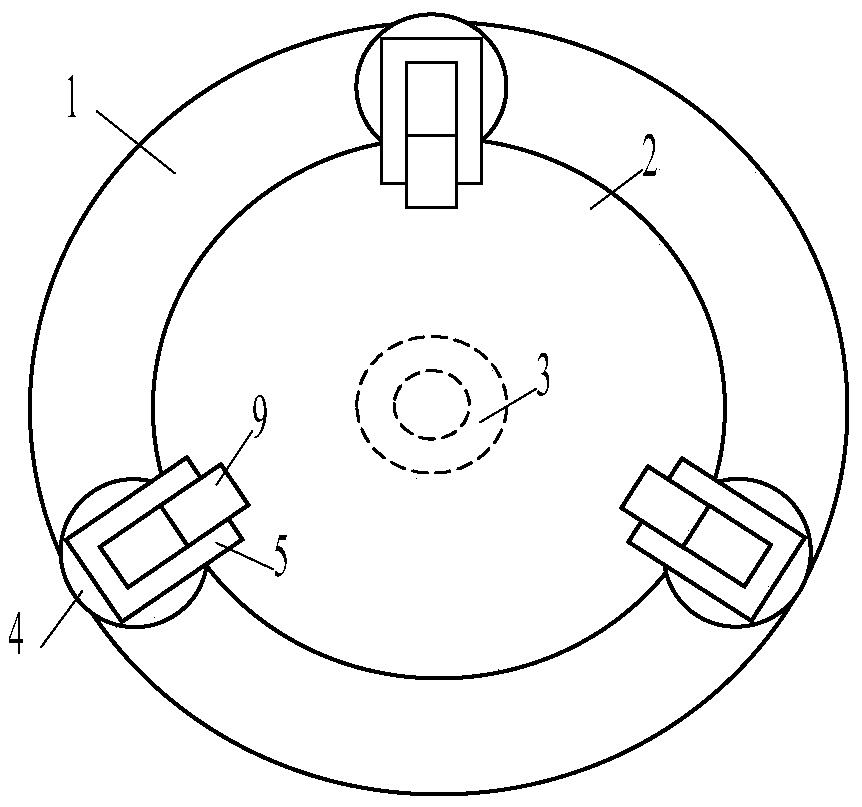

[0013] exist figure 1 and figure 2 In the schematic diagram of the flexible hand of the four-degree-of-freedom 3SPRR+SP hybrid robot shown, the SP-type intermediate linear drive branch 3 is set at the center of the moving platform 2 and the base 1, and the three SPRR-type flexible finger-containing drive branches are located on the moving platform. Circumferentially evenly distributed between the machine base; 3 circumferentially evenly distributed ball sub-supports and 1 central ball sub-support are provided on the machine base; 1 central vertical through-hole is provided on the moving platform;

[0014] The SP-type drive branch is composed of a linear electric cylinder 4, its upper end is fixedly connected with the center vertical through hole of the moving platform, and its lower end is connected with the center ball seat ball pair of the machine base; the arm frame 5 in the SPRR-type drive branch with flexible fingers is Rectangular square frame, the two sides of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com