A precise desulfurization method for circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, applied in chemical instruments and methods, separation methods, combustion methods, etc., can solve the problems of reduced desulfurization rate, high sulfur fixation cost, and high limestone escape rate, so as to reduce secondary decomposition and improve Sulfur fixation efficiency, effect of reducing escape rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Coal gangue and coal washing slime from the Antaibao Open-pit Coal Mine in Shanxi Pingshuo were selected, and limestone coarse powder and fine powder made by Shanxi Pingshuo Coal Gangue Power Generation Co., Ltd. were used as desulfurizers. Experiments were carried out on a bed boiler.

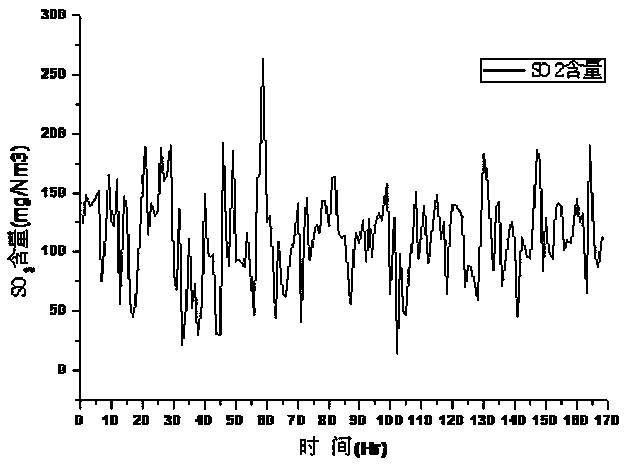

[0030] Take 23kg of fine limestone powder (particle size ≤ 0.2mm) and 0.3kg of modified fly ash as desulfurizer and binder, use a mixer to mix it with 30kg of coal slime, and use a roller forming machine for cold pressing Molding, preparing slime briquettes, and then layering it with 270kg of coal gangue and 23kg of limestone coarse powder on the conveyor belt, passing through the conveyor belt into the circulating fluidized bed boiler for combustion, and then using the circulating fluidized bed to return the material bin according to the flue mouth SO 2 Concentration, control spraying a small amount of limestone. The calcium-sulfur ratio of the above-mentioned ingredients and methods...

Embodiment 2

[0032]Coal gangue and coal washing slime from the Antaibao Open-pit Coal Mine in Shanxi Pingshuo were selected, and limestone coarse powder and fine powder made by Shanxi Pingshuo Coal Gangue Power Generation Co., Ltd. were used as desulfurizers. Experiments were carried out on a bed boiler.

[0033] Take 28kg of limestone fine powder (particle size ≤ 0.2mm) and 2kg of modified fly ash as desulfurizer and binder, use a mixer to mix it with 150kg of coal slime, and use a double-roller forming machine for cold pressing , to prepare slime briquettes, and then layer it with 1350kg of coal gangue and 120kg of limestone coarse powder on the conveyor belt, enter the circulating fluidized bed boiler through the conveyor belt for combustion, and then use the circulating fluidized bed to return the material bin according to the flue mouth. SO 2 Concentration, control spraying a small amount of limestone. Using the above-mentioned ingredients and methods, the calcium-sulfur ratio is ab...

Embodiment 3

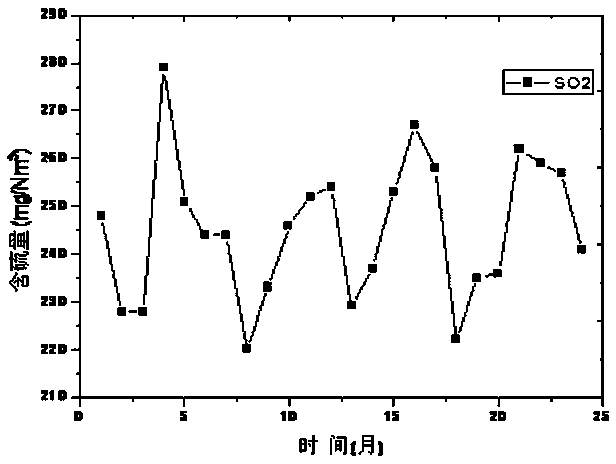

[0035] Coal gangue and coal washing slime from Antaibao open-pit coal mine in Pingshuo, Shanxi were selected, and limestone powder made by Shanxi Pingshuo Coal Gangue Power Generation Co., Ltd. was used as a desulfurizer, and experiments were carried out on the company's 235t / h circulating fluidized bed boiler.

[0036] 270kg of coal gangue and 46kg of coarse limestone powder are spread on the conveyor belt in layers, and enter the circulating fluidized bed boiler through the conveyor belt for combustion. Reuse the circulating fluidized bed back to the bin according to the SO at the flue outlet 2 Concentration, control spraying a small amount of limestone. Using the above two feeding methods, the calcium-sulfur ratio is about 2.5, the daily consumption of coal gangue is about 890 tons, and the limestone powder is about 90 tons. After monitoring, the concentration of sulfur dioxide in the exhaust gas after the dust collector is 248mg / m 3 , the desulfurization rate is 86%.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com