Method for producing pleocidin by adopting saccharopolyspora spinosa through fermentation

A technology of Saccharomyces spinosa and fermentation strains, which is applied in the field of spinosad production, and can solve the problems of the large impact of spinosad fermentation, the root cause of inability to eliminate foam, and the low efficiency of mechanical defoaming, so as to solve the problem of insufficient carbon source , Stable output and less foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 S. spinosa fermentation medium

[0016] In this example, the formula of S. spinosa fermentation medium is: high-temperature soybean cake powder 10g / L, cornstarch 30g / L, glucose 30g / L, corn steep liquor 20g / L, cottonseed cake powder 10g / L, yeast Dip powder 5g / L, calcium carbonate 5g / L and soybean oil 5g / L, prepared with water. Adjust the pH of the medium to 7.0 before sterilization, and sterilize at 121°C for 30 minutes.

Embodiment 2

[0017] Embodiment 2 utilizes the method for producing spinosad by fermentation of Saccharopolyspora spinosa

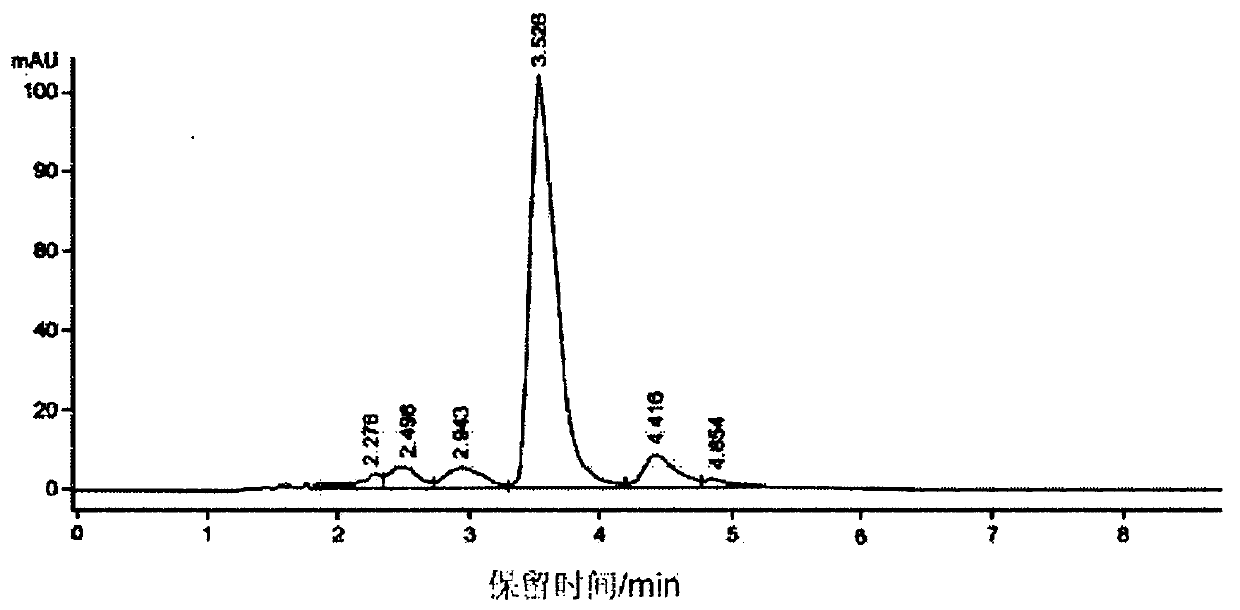

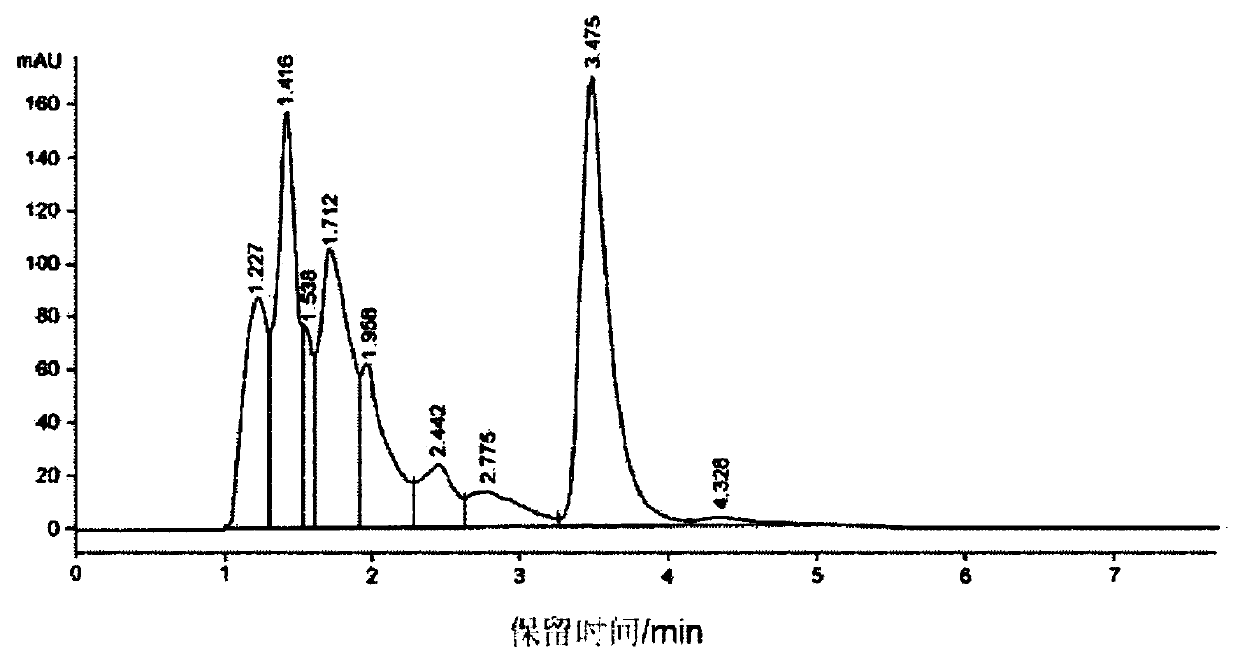

[0018] Saccharopolyspora spinosa (Saccharopolyspora spinosa) Z68 was used as the fermentation strain, and the fermentation medium of Example 1 was used to inoculate the Saccharopolyspora spinosa seed liquid in the above fermentation medium according to the inoculation ratio of 5-15% (v / v). Carry out fermentation culture. The fermentation conditions are: 28°C, rotation speed 200rpm, aeration ratio 1:0.5, tank pressure 0.03MPa, dissolved oxygen controlled above 40%, and fermentation period of 192hr. At 96 hours after the start of fermentation, soybean oil was added for the first time to a final concentration of 30 g / L, and glucose was added to a final concentration of 30 g / L. At 144 hours after the start of fermentation, glucose was added for the second time to a final concentration of 30 g / L.

[0019] Wherein, the preparation method of S. spinosa seed solution is: digg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com