A multi-frequency coupled vibration aging system and method

A vibration aging and frequency technology, which is used in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of limited adjustment and low energy at key frequency points, so as to improve efficiency, reduce workload, and improve residual stress elimination effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] With reference to the drawings, the present invention will be further explained:

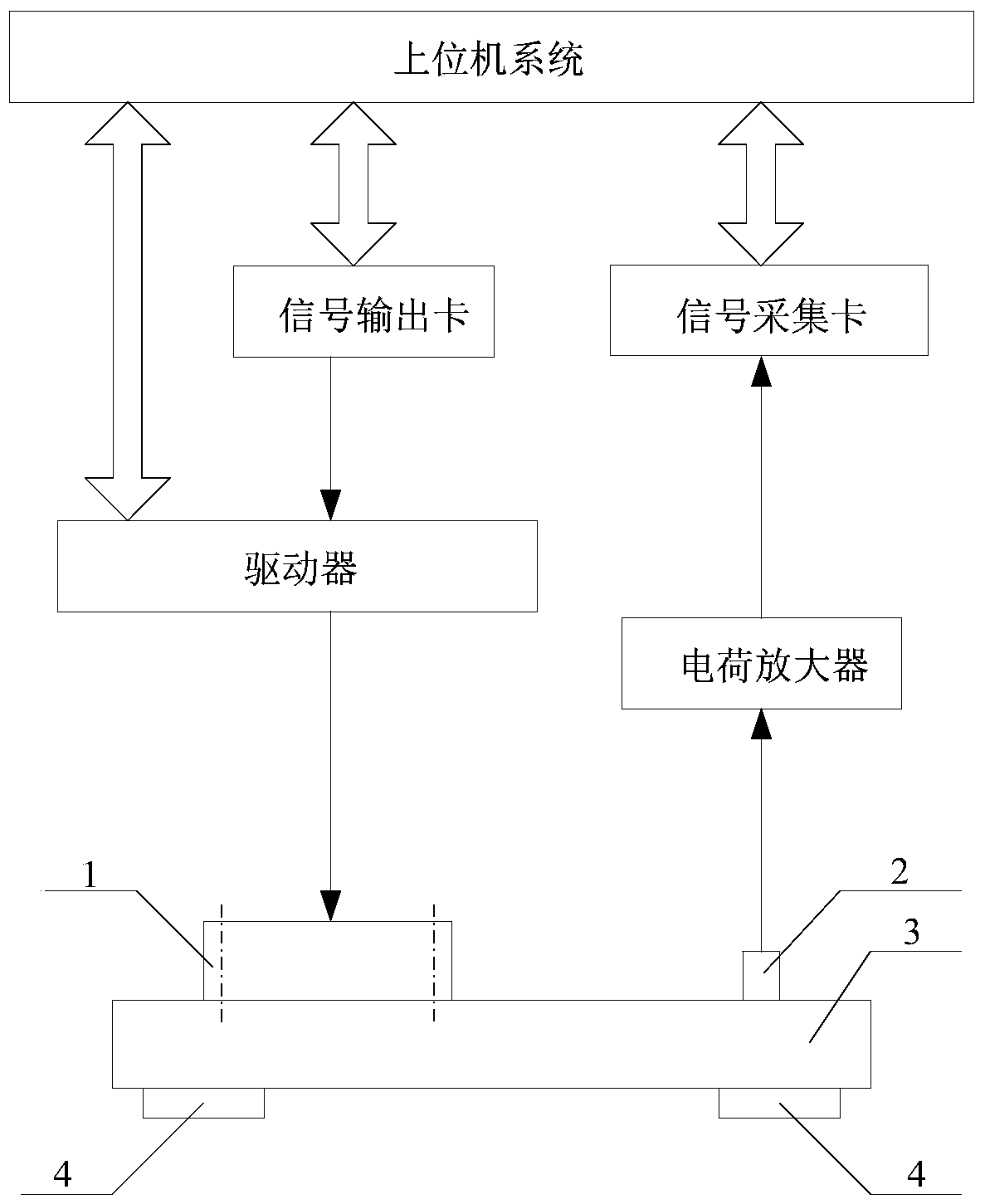

[0031] Multi-frequency coupling vibration aging system, including host computer system, signal output card, driver, vibration exciter 1, acceleration sensor 2, charge amplifier, signal acquisition card, support device 4; vibration exciter 1 is fixed on the surface of workpiece 3, workpiece 3 Installed on the elastic support device 4, the host computer system control signal output card outputs a synthesized excitation signal; the synthesized excitation signal output by the signal output card is input to the exciter 1 through the driver, and then drives the exciter 1 to generate vibration; The acceleration sensor 2 is installed on the workpiece 3. The acceleration sensor 2 is connected with the input channel of the charge amplifier, the output channel of the charge amplifier is connected with the signal acquisition card, and the signal acquisition card is connected with the upper computer syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com