Method for eliminating residual stress of aluminum alloy aviation forge cylinder

A technology of residual stress and aluminum alloy, which is applied in the field of residual stress elimination of aviation forging cylinders, can solve the problems that it is difficult to apply residual stress elimination of larger size forging cylinders, and can achieve good residual stress reduction effect, eliminate residual stress, Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

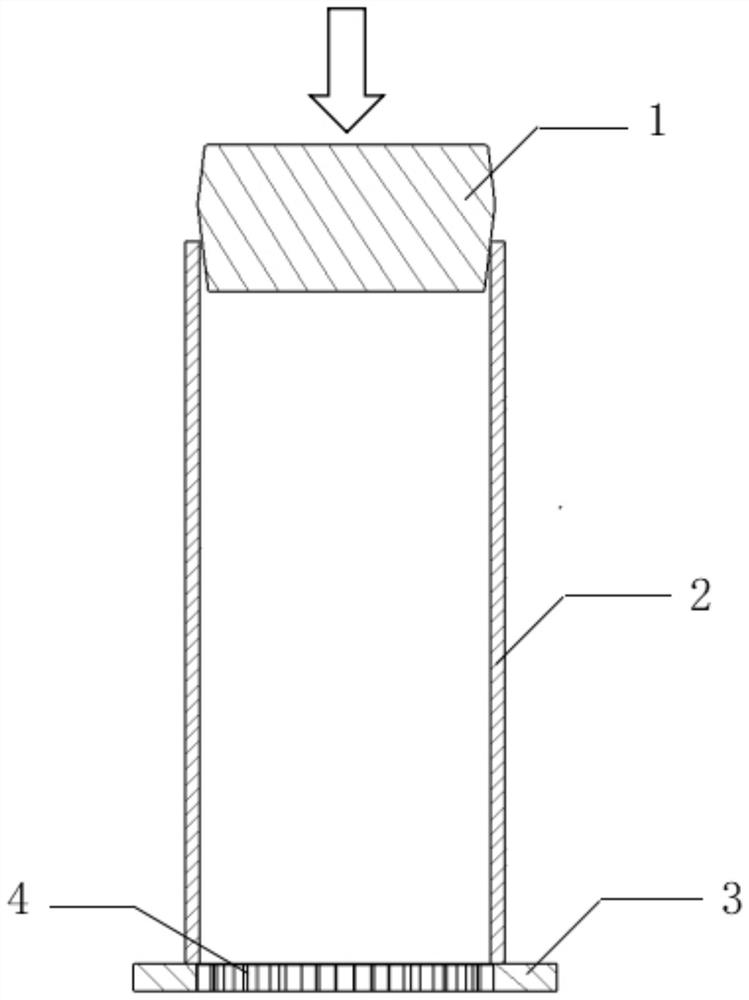

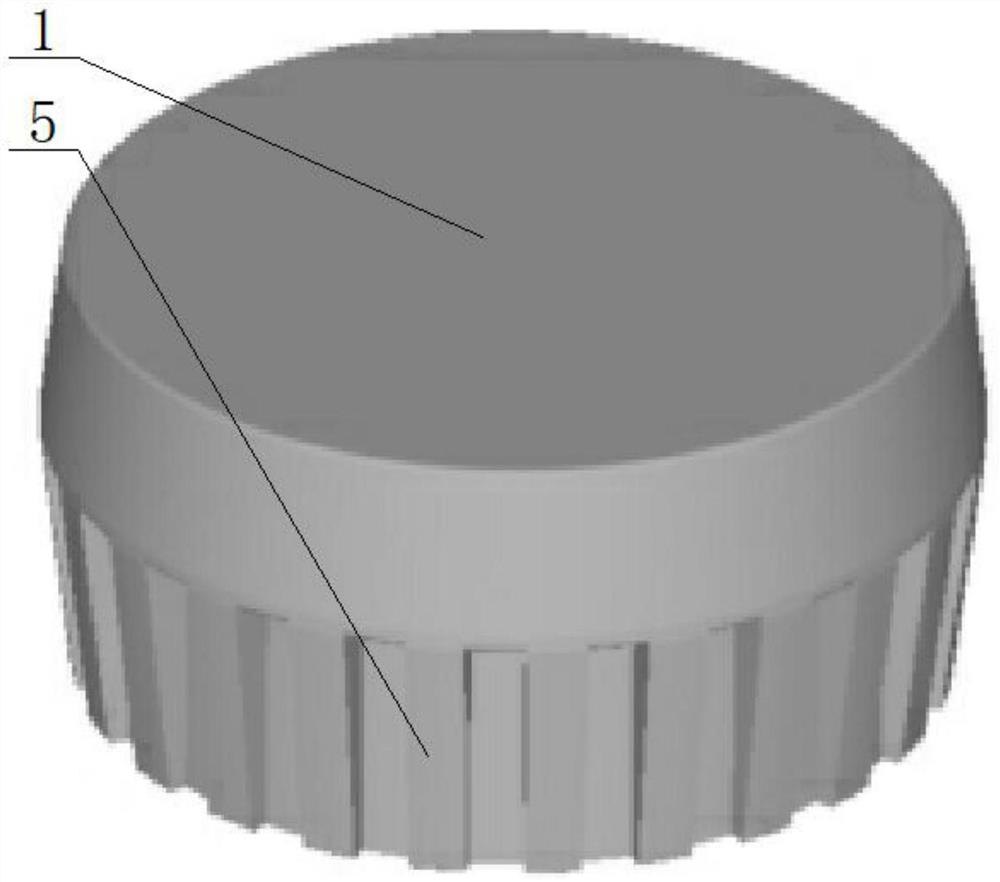

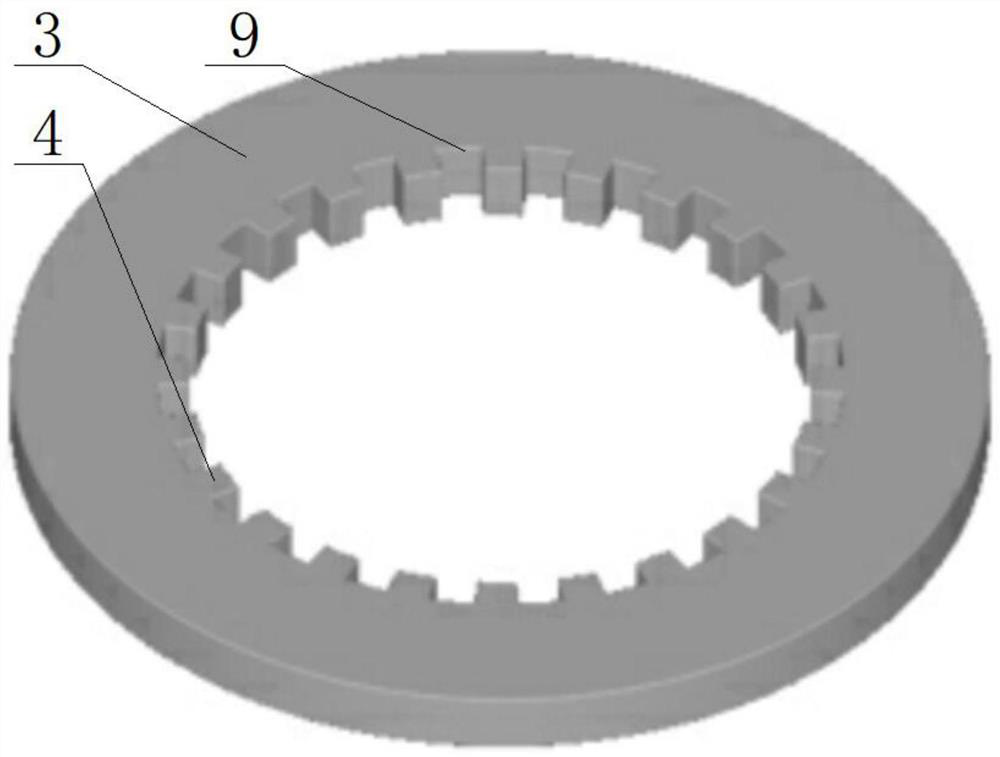

[0026] In this embodiment, a 7075 aluminum alloy forged barrel 2 is taken as an example to illustrate the method and process of eliminating residual stress. The final specifications required for the 7075 cylindrical product are the outer diameter of 1150±2mm, the inner diameter of 1050±2mm, the height requirement of 2550±10mm, and the wall thickness of the forging is 50±2mm. According to the final size requirements, the production size of the hot forged part of the forging cylinder 2 is designed, the inner diameter is 986±4mm, the outer diameter is 1098±4mm, and the height requirement is 2610mm±10mm;

[0027] Step 1: On a 60MN free forging hydraulic press, use the free forging billet and the horse bar reaming method to produce hot forgings that meet the design specifications, and then slowly cool to room temperature in the air. Due to the wall thickness of the hot forgings produced by the reaming method There will be a small difference, so the inner and outer surfaces of the forg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com