Dry cutting method of steel pipe plug piles in foundation pits in cofferdams of immersed tunnels

A technology of steel pipes for immersed tunnels and foundation pits, which can be applied to sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as unsatisfactory construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

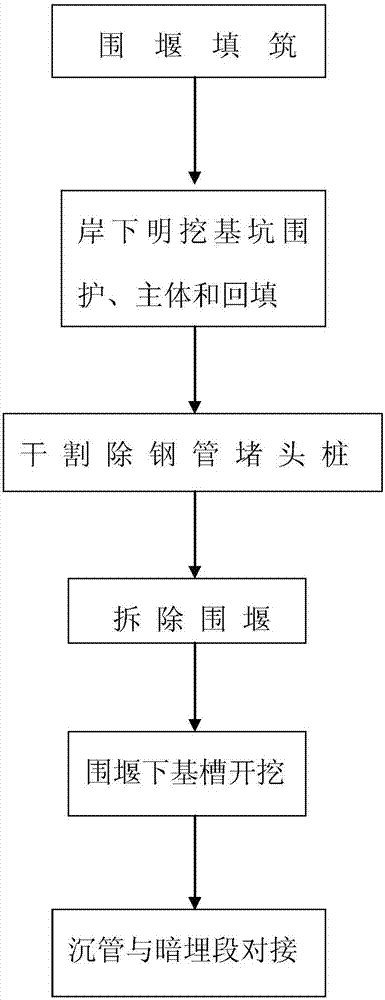

[0030] Such as figure 1 Shown in detail, the dry cutting method of steel pipe plug piles in foundation pit in the cofferdam of immersed tunnel tunnel provided by the present invention is specified, and the method comprises:

[0031] Step 1, cofferdam filling step

[0032] The cofferdam is a sand-filled long-tube bag cofferdam, and the long-tube sandbags are filled with sand by sand ship + sand pump ship + laying ship. During this period, the process construction of auxiliary works such as plastic concrete cut-off wall and cofferdam slope protection will be interspersed. The overall filling sequence includes construction of long sand-filled pipes and sandbags divided into two working faces, and construction is carried out from the middle of the waterside side of the cofferdam along the axis to the shorelines on both sides.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com