Hydraulic system of overflow-loss-free loader and control method of hydraulic system

A technology of hydraulic system and overflow loss, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Scale promotion and other issues to achieve the effect of improving energy utilization, strong anti-pollution ability, and improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

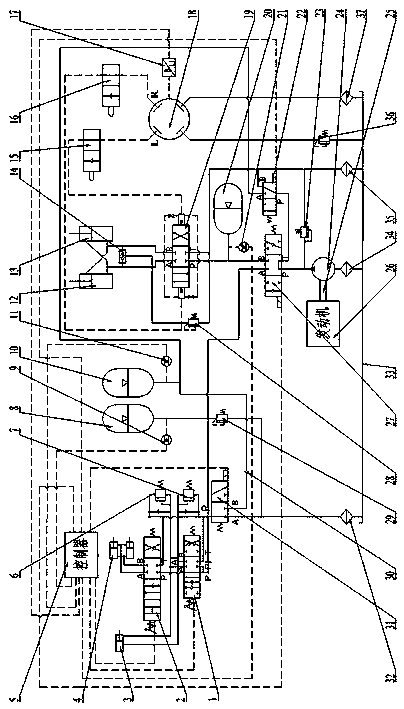

[0020] see figure 1 , is an embodiment of the present invention, the system is composed of an engine, a transmission shaft, a filter, a fuel tank, a quantitative pump, a three-position four-way reversing valve, a two-position three-way reversing valve, an accumulator, a steering gear, and a steering limiter. Position valve, flow amplification valve, steering cylinder, safety valve, sensor, one-way valve, double-acting safety valve, multi-way valve, bucket cylinder, boom cylinder and controller. The accumulator includes a high-pressure accumulator 8, a low-pressure accumulator 10 and a steering accumulator 20; the steering limit valve includes a left steering limiting valve 15 and a right steering limiting valve 16; the flow amplifying valve Including the first three-position four-way reversing valve 19, or the gate type shuttle valve 14 and the second safety valve 28; the sensor includes the first pressure sensor 9, the second pressure sensor 11, the third pressure sensor 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com