Wear-resisting sintering wind box branch pipe and online repair method

A bellows and pipe technology, which is applied to the production process of the main charge, can solve the problems of fast wear and high air leakage rate of the flue, and achieve the effects of preventing cracking and falling off, good ductility, and solving the problems of wear and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the structure, function and effect of the present invention, the following preferred embodiments are now used in conjunction with the accompanying drawings to describe in detail.

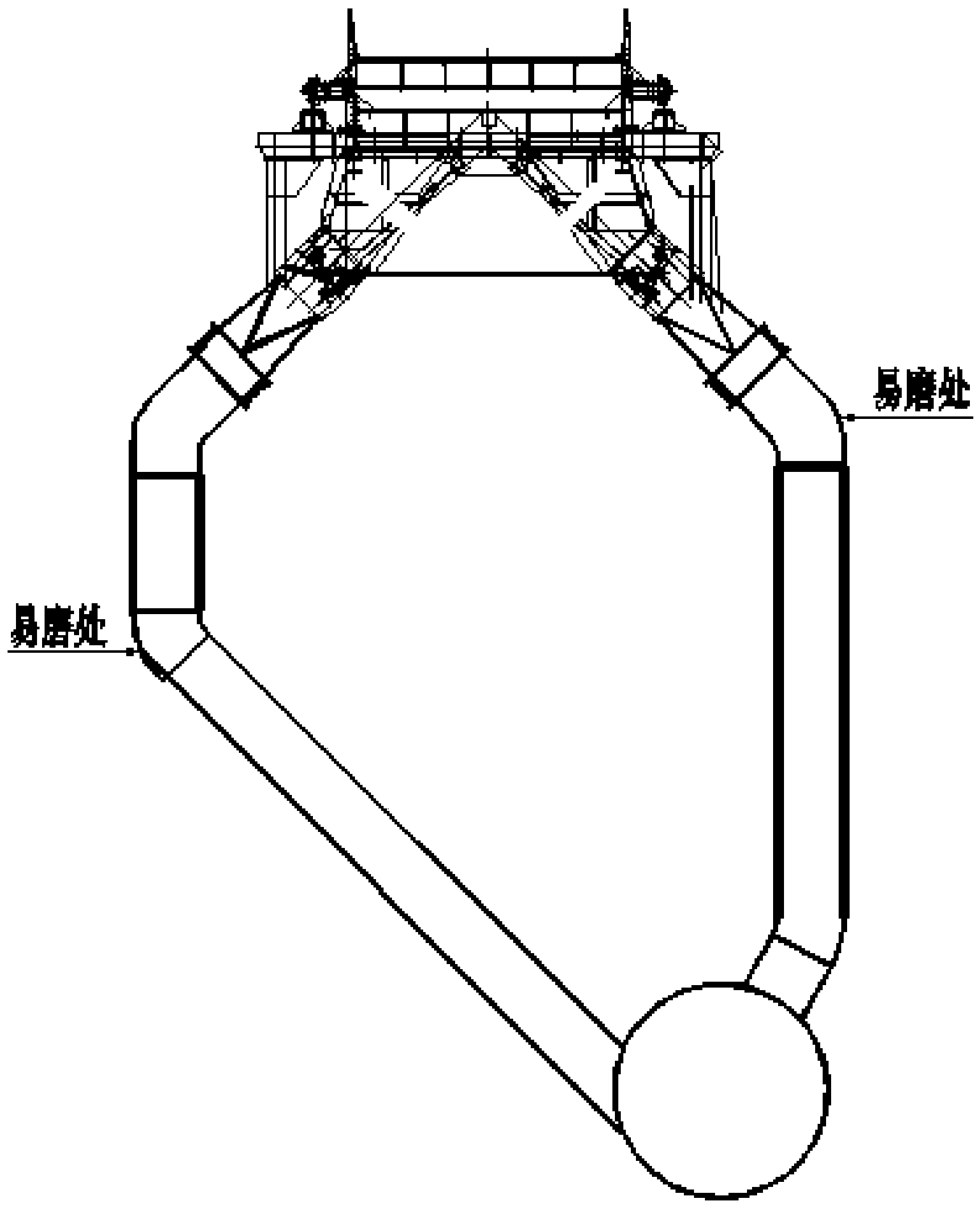

[0025] Depend on figure 1 It can be seen from the structure shown that the turning point of the bellows branch is the place where the wear is the most severe due to the high-speed erosion of the sinter particles.

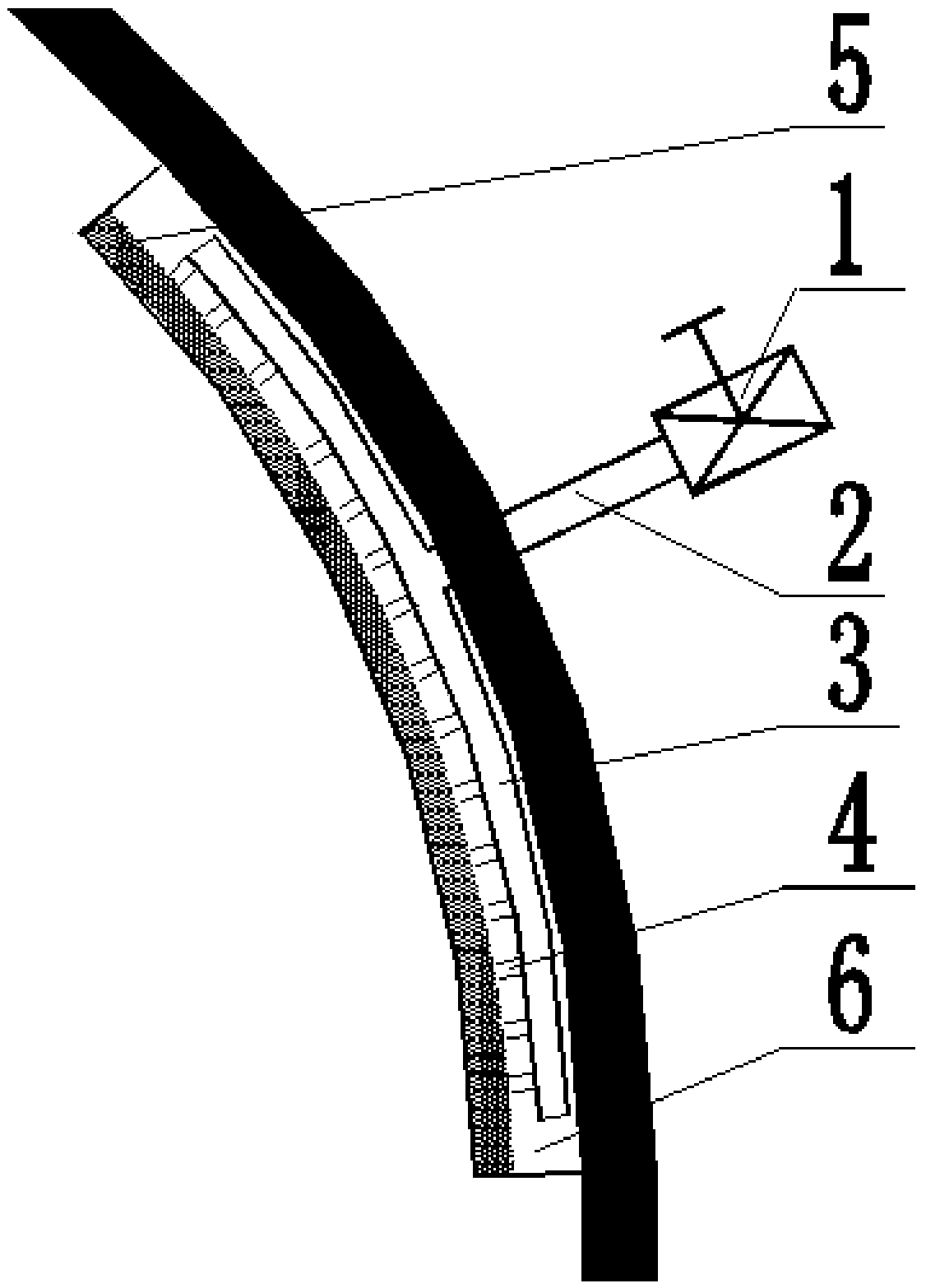

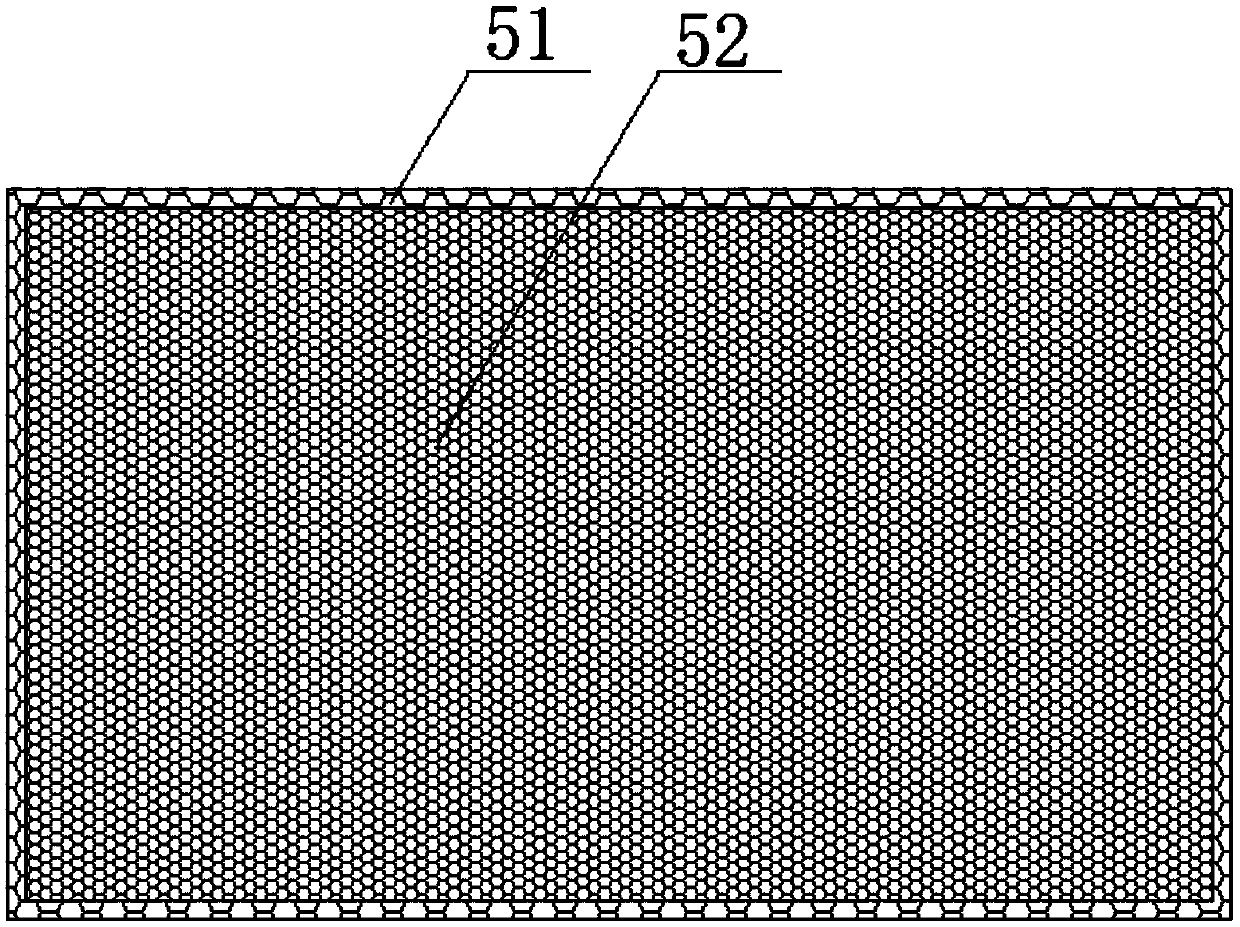

[0026] Such as image 3 , use SL8303 (500°C high temperature resistant glue) to bond 30-mesh stainless steel wire mesh to 2-mesh stainless steel embossed screen. It is a skeleton with a rigid 30-mesh stainless steel wire composite wire mesh.

[0027] Preferably, the skeleton net 5 can also be a 30-mesh silica gel net.

[0028] In the easy-to-wear area of the inner wall of the bellows branch pipe, at intervals of 10cm×10cm, use SL8303 high-temperature-resistant glue to seal 1cm 2 Paste the high temperature resistant fluorosilicone rubber block on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com