Special X-ray fluorescence energy spectrometer for high-precision cement industry

An X-ray, high-precision technology, applied in the field of X-ray fluorescence detection, can solve the problems of high failure rate, high maintenance cost, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

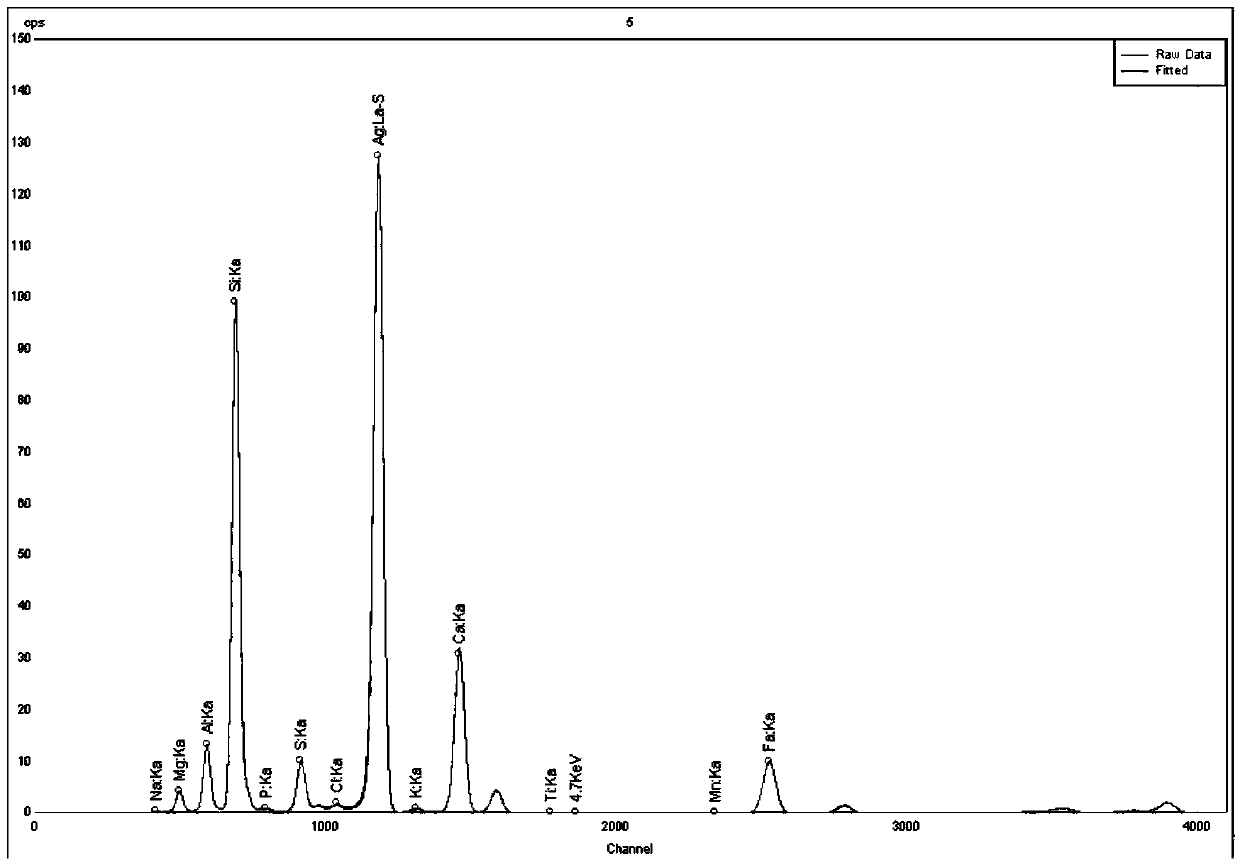

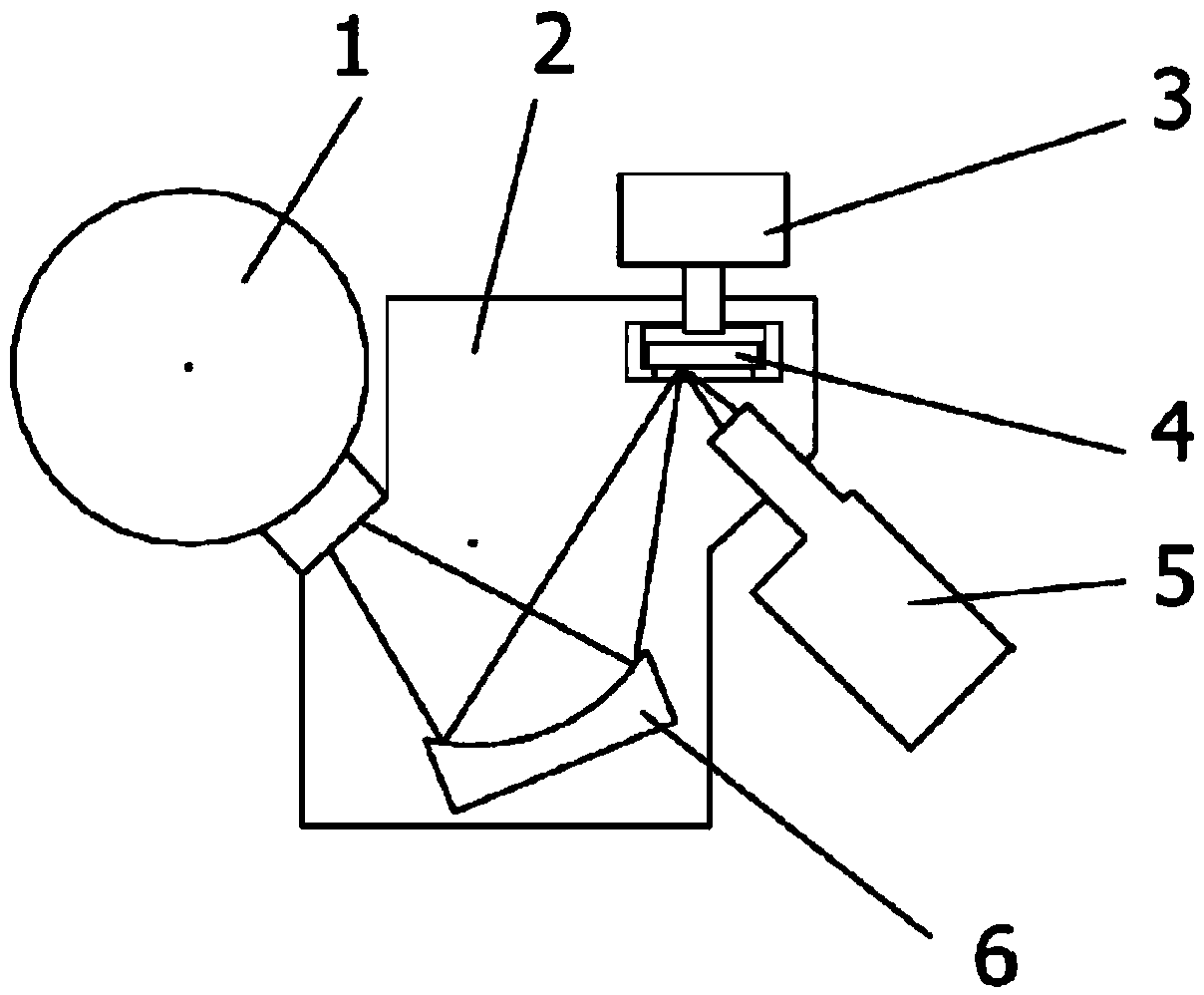

[0018] A special X-ray fluorescence energy spectrometer for high-precision cement industry, such as image 3 As shown, it includes an X-ray tube 1, a diffraction crystal 6, a sample stage 4, and a detector 5, and the diffraction crystal 6 is an all-focus hyperboloid curved crystal prepared by Ge(111) crystal; the all-focus hyperboloid curved crystal The radius of the Rowland circle is R300mm; the X-ray tube 1 is an X-ray tube with an air-cooled thin beryllium window of 50W, the focal spot of the X-ray tube is 100 μm-350 μm, and the target material used in the X-ray tube is an Ag target material; The sample stage 4 is provided with a spin mechanism 3 for automatic rotation of the sample stage 4; the diffraction crystal, the sample stage, and the detector are all placed in the vacuum airtight space 2, so that the entire optical path propagates in the vacuum environment.

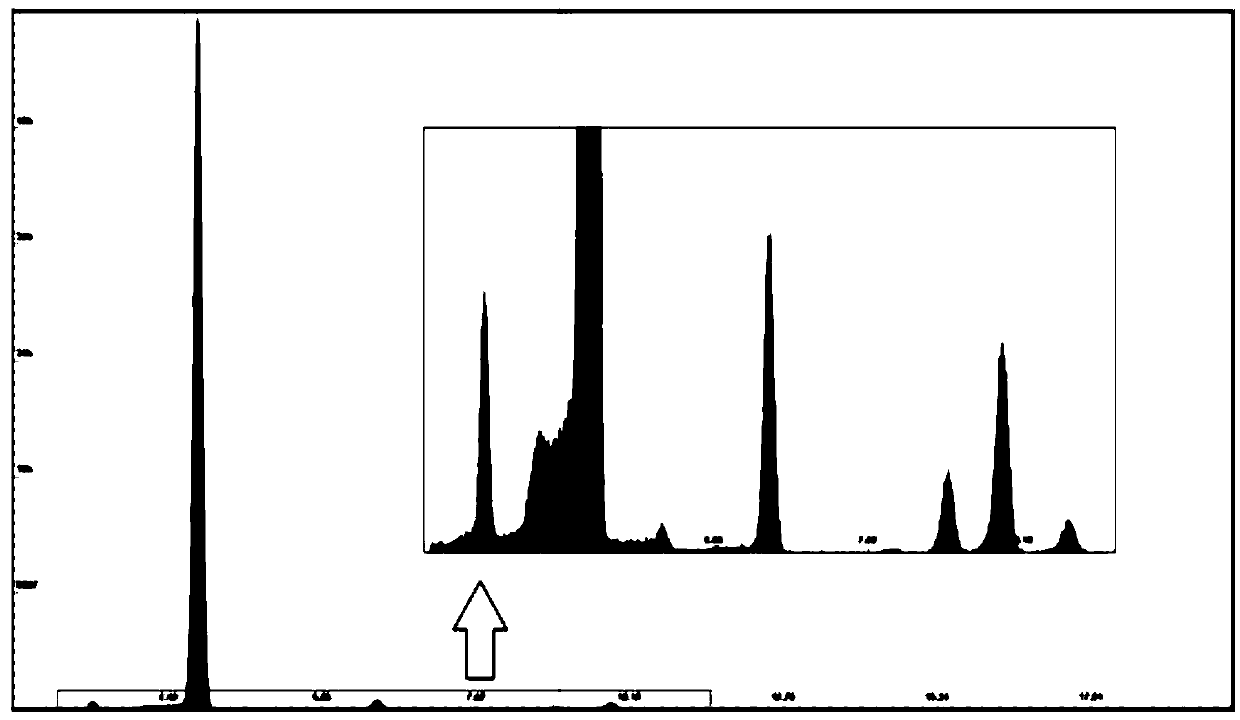

[0019] The X-ray fluorescence energy spectrometer in this embodiment, the optical path is in a vacuum enviro...

Embodiment 2

[0028] The high-precision X-ray fluorescence spectrometer dedicated to the cement industry in this embodiment is different from Embodiment 1 in that the radius of the Rowland circle of the all-focus hyperboloid curved crystal used is 50 nm.

[0029] In this embodiment, the radius of the Rowland circle of the all-focus hyperboloid curved crystal can be arbitrarily selected between 50 nm and 300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com