Transformer cooling coil structure

A technology for cooling coils and transformers, which is applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, transformer/inductor parts, etc. Problems such as small heat exchange area achieve the effects of not affecting insulation performance, preventing leakage, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

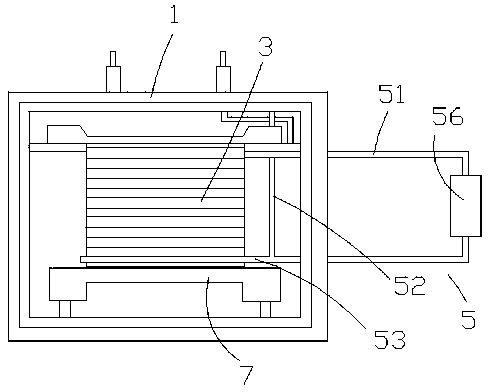

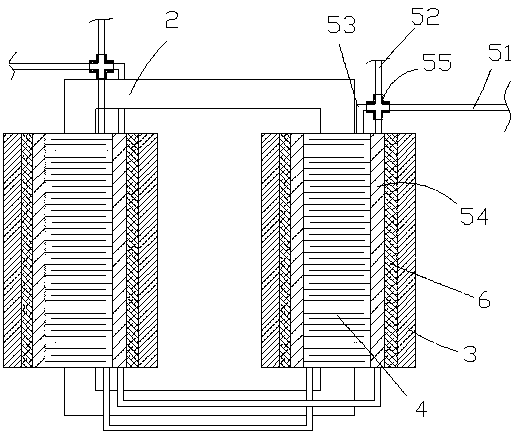

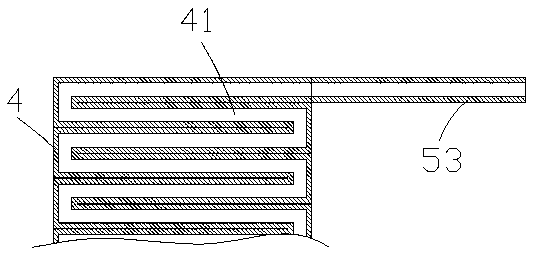

[0025] The transformer cooling coil structure of the present invention includes a test transformer housing 1 filled with insulating gas. The test transformer housing 1 is provided with an iron core 2, a high-voltage coil 3 and a low-voltage coil 4, a high-voltage coil 3 and a low-voltage coil. The coil 4 is coaxially arranged on the iron core 2, and the high-voltage coil 3 is located outside the low-voltage coil 4, wherein: the cooling coil structure also includes a conductive cooling cycle structure 5, and the conductive cooling cycle structure 5 includes a connecting pipe 51, a wire segment 52, and an integrated pipe 53 , the outer cooling pipe 54, the four-way valve 55 and the refrigeration equipment 56, the outer cooling pipe 54 surrounds the outer side of the low-voltage coil 4, and the inner pipe wall of the outer cooling pipe 54 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com