Cell stack, lithium-air secondary battery unit and assembly method thereof

A technology of secondary battery cells and cells, which is applied to electrical components, fuel cell type half cells, primary cell type half cells, and hybrid batteries, etc. , low structural stability, etc., to achieve the effect of controllable gas flow and pressure, convenient assembly and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

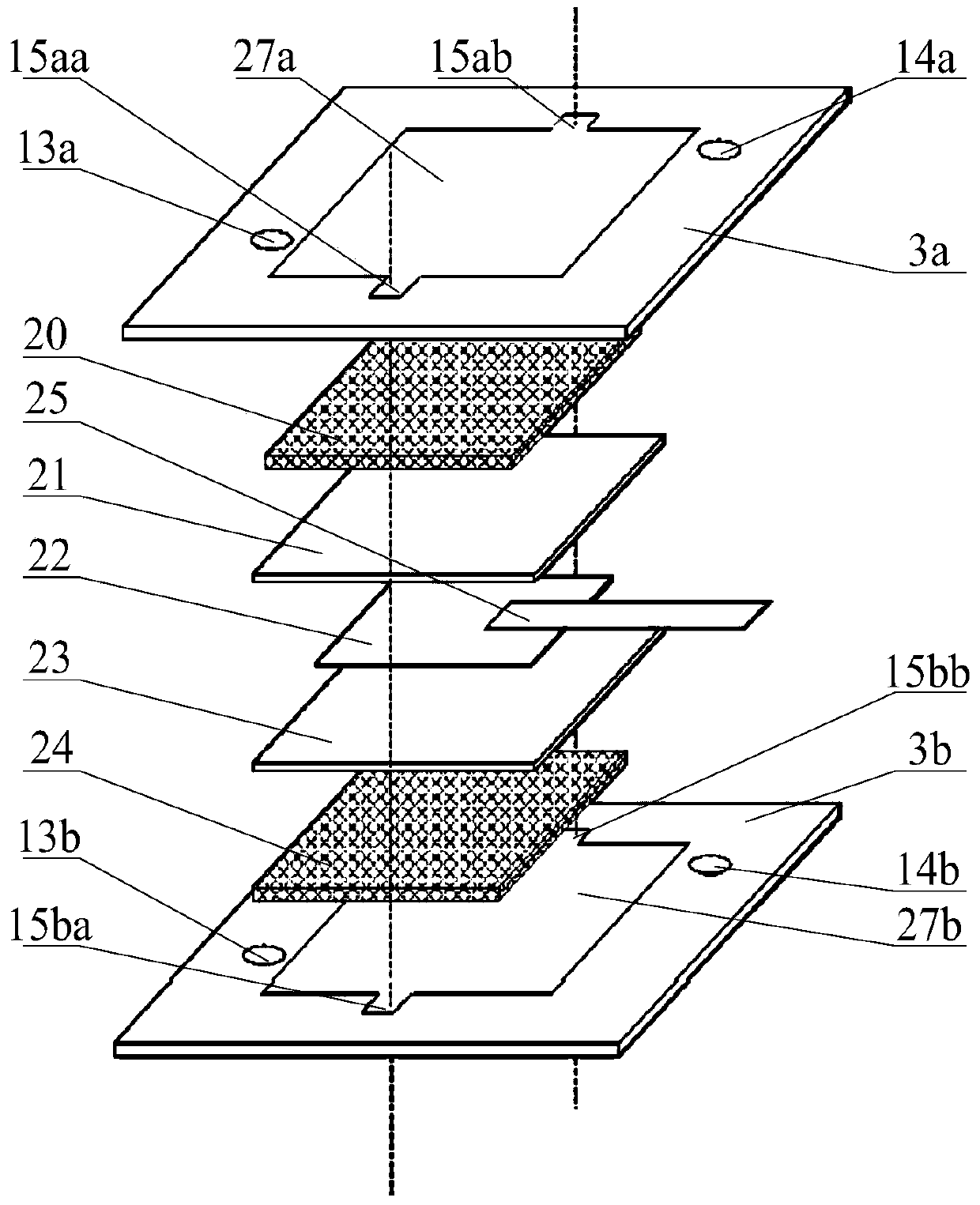

[0077] See attached figure 1 The cell stack provided in Example 1 of the present invention includes an upper sealing gasket 3a, an upper air positive electrode 20, an upper diaphragm 21, a metal lithium negative electrode 22, a lower diaphragm 23, a lower air positive electrode 24, a negative electrode tab 25, and a lower sealing gasket sheet 3b, the center of the upper sealing gasket 3a is provided with a first through hole 27a, the upper air positive electrode 20 is assembled in the first through hole 27a, and a first upper sealing gasket is also opened between the upper air positive electrode 20 and the upper sealing gasket 3a Sheet liquid injection hole 15aa, the second upper sealing gasket liquid injection hole 15ab; the center of the lower sealing gasket 3b is provided with a second through hole 27b, and the lower air positive electrode 24 is assembled in the second through hole 27b, and the lower air positive electrode 24 is connected to the lower air positive electrode ...

Embodiment 2

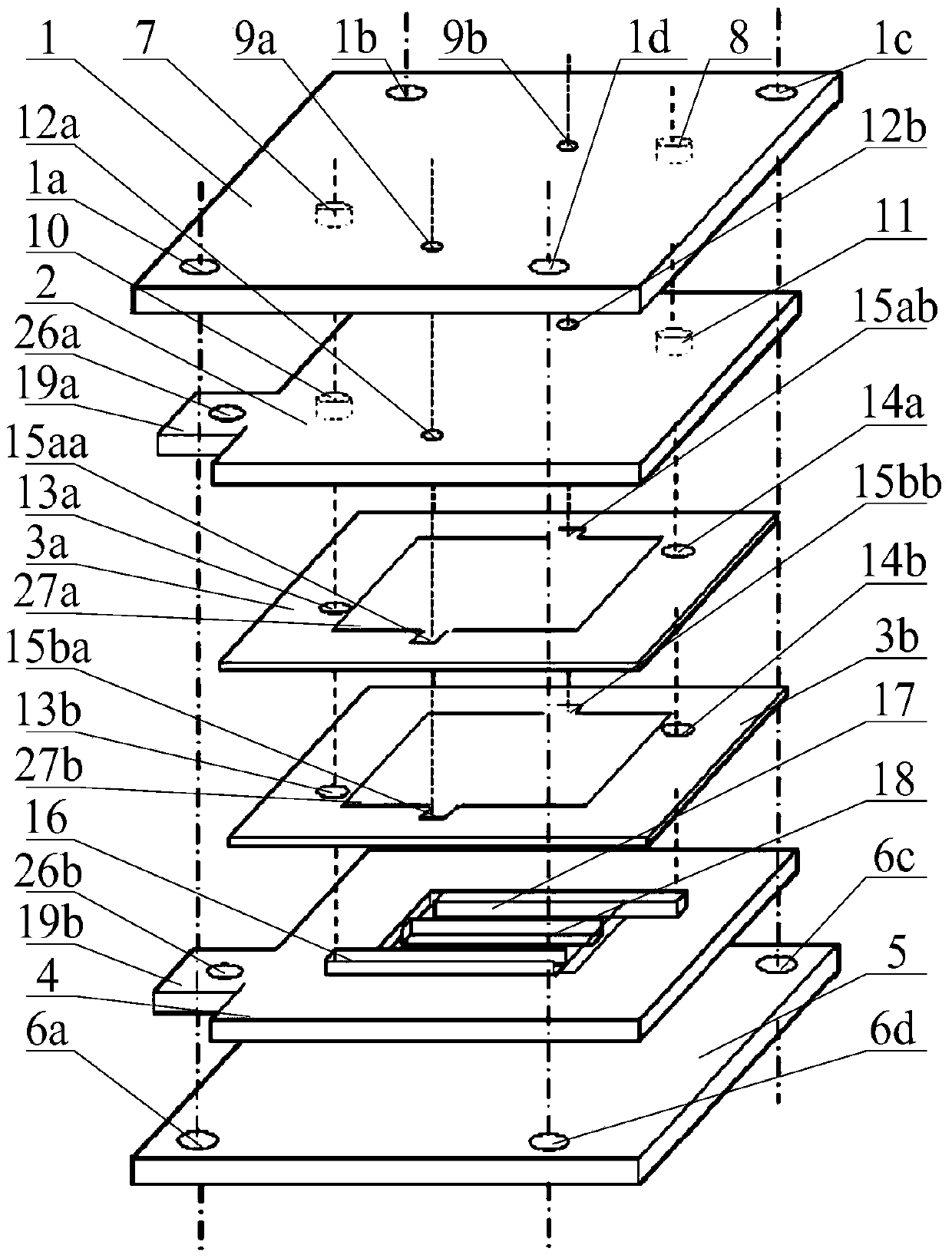

[0084] See attached figure 2 The lithium-air secondary battery unit provided in Embodiment 2 of the present invention includes, from top to bottom, an upper end plate 1, an upper gas deflector 2, a cell stack provided in Embodiment 1 of the present invention, a lower gas deflector 4, Lower end plate 5, upper end plate 1 is provided with upper end plate airway hole inlet 7, upper end plate airway hole outlet 8, upper gas deflector 2 is provided with upper gas deflector airway hole inlet 10, upper gas diversion Plate airway hole outlet 11, the lower surface of the upper gas deflector 2 and the upper surface of the lower gas deflector 4 are provided with a gas flow guide mechanism, the upper end plate airway hole inlet 7, the upper gas deflector airway hole inlet 10 , Upper sealing gasket airway hole inlet 13a, lower sealing gasket airway hole inlet 13b, flow guide mechanism, lower sealing gasket airway hole outlet 14b, upper sealing gasket airway hole outlet 14a, upper gas defl...

Embodiment 3

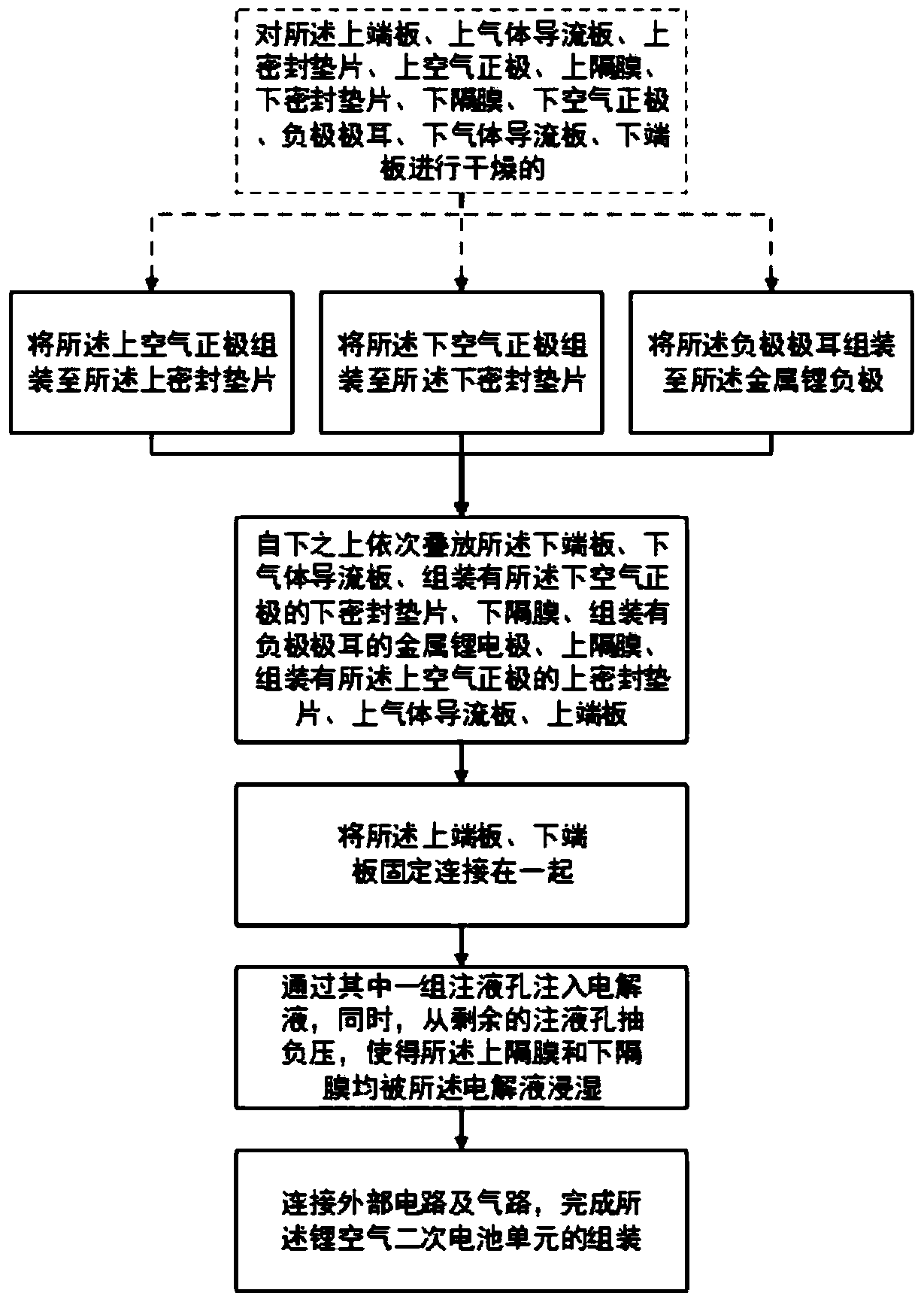

[0093] See attached image 3 , the method for assembling the lithium-air secondary battery unit provided in Embodiment 3 of the present invention comprises the following steps:

[0094] Step 1: Assemble the upper air positive electrode 20 to the upper sealing gasket 3a; assemble the lower air positive electrode 24 to the lower sealing gasket 3b; assemble the negative electrode tab 25 to the metal lithium negative electrode 22;

[0095] Step 2: stack the lower end plate 5, the lower gas deflector 4, the lower sealing gasket 3b assembled with the lower air positive electrode 24, the lower diaphragm 23, and the metal lithium electrode 22 assembled with the negative electrode tab 25 from the bottom to the top. The upper diaphragm 21, the upper sealing gasket 3a assembled with the upper air positive electrode 20, the upper gas deflector 2, and the upper end plate 1;

[0096] Step 3: Fix the upper end plate 2 and the lower end plate 5 together;

[0097] Step 4: Inject the electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com