Four-section type mandible molding plate

A mandible and forming plate technology, which is applied in the field of medical devices, can solve problems such as unfavorable beginners’ operation, reduced strength of titanium plates, and metal fatigue, so as to reduce the risks of nail hole deformation and metal fatigue, reduce in-plane bending, The effect of restoring the shape of the mandible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

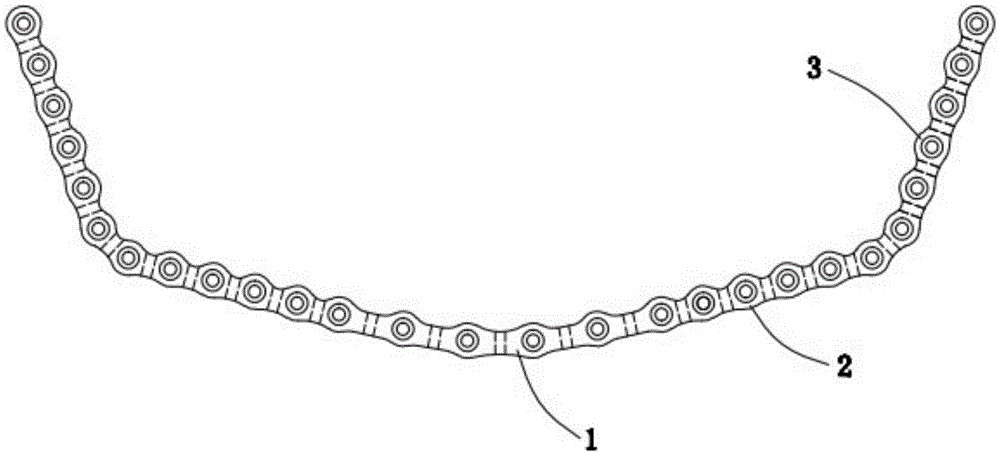

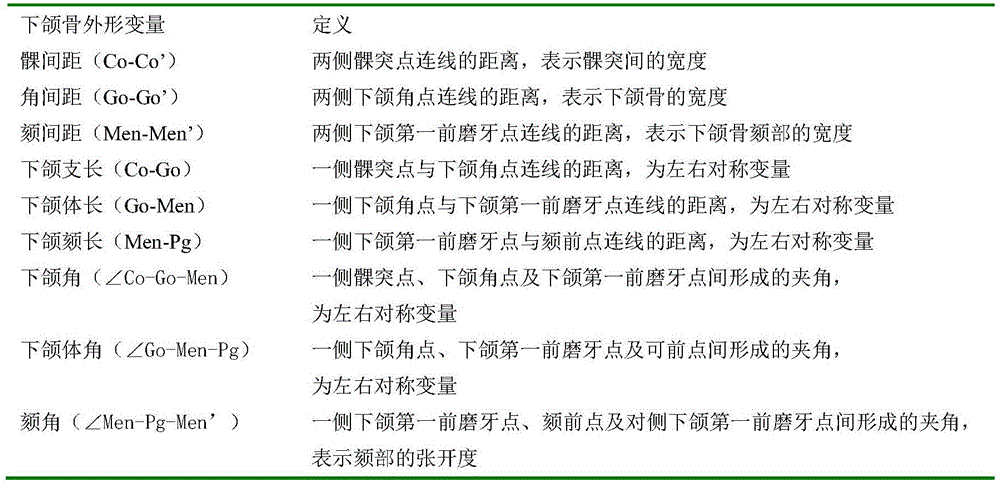

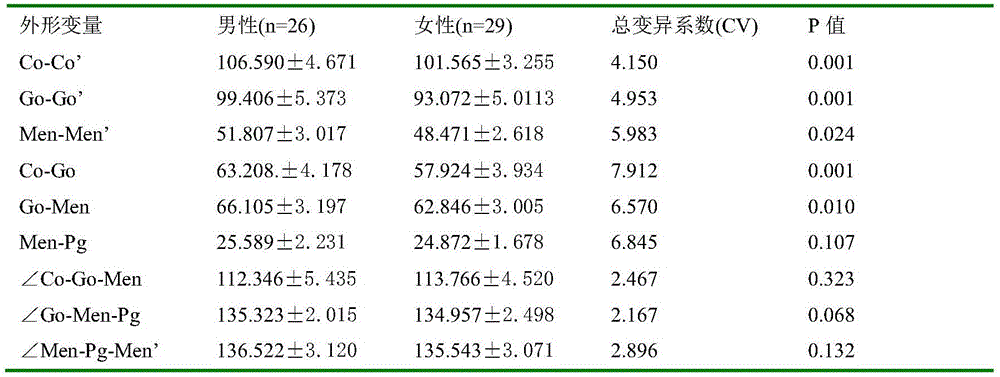

[0025] In the previous study, through the morphological analysis of the normal adult mandible, the shaping parameters of the horizontal part of the mandible were determined, and the universal fibula shaping plate was designed and produced based on this, realizing the concept of "four-segment" rapid mandible shaping.

[0026] Theoretical basis of the present invention:

[0027] 1. The mandible is composed of a vertical part and a horizontal part. The horizontal part of the mandible is composed of the mandibular body and the chin. Studies have reported that its outline is similar to a parabolic structure, which is a difficult point for mandibular reconstruction and bone shaping. Clinical practice has found that the horizontal part of the mandible is almost a straight line after the first mandibular premolar, while the curvature of the mandibular chin between the mental foramen is relatively large, and the premental point (Pg) is the most, so the mandibular first premolar The mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com