Cement base material for anti-electromagnetic radiation building and preparation method thereof

A technology for preventing electromagnetic radiation and cement-based materials, which is applied in building materials, buildings, building components, etc. to achieve integration, broad market prospects, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

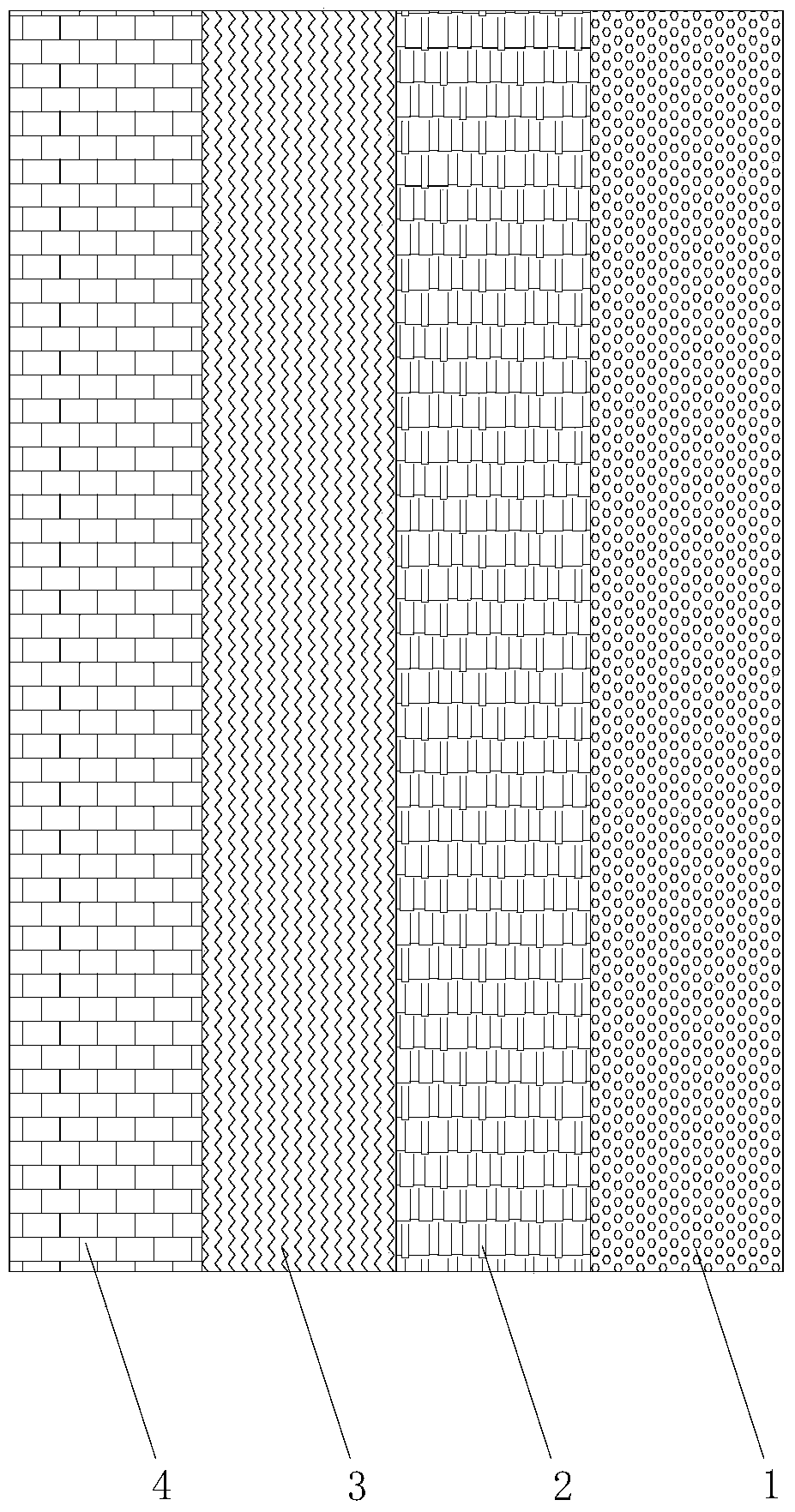

[0038] figure 1 It is a schematic diagram of the structure of the electromagnetic radiation-proof building cement-based material used on the building wall 4 according to the embodiment of the present invention. see figure 1 , the specific preparation process of the cement-based material for the anti-electromagnetic radiation building of the present embodiment is as follows:

[0039] Raw material preparation for the concrete mixture of the reflective layer 3: the cementitious material is composed of cement, quartz sand, mineral powder and microsilica, and the mass ratio of cement, quartz sand, mineral powder, microsilica and water reducer is 1:1.1 :0.14:0.2:0.02, the water-binder ratio is 0.21, the third electromagnetic functional material selects steel fiber and graphite powder, the mixing amount of steel fiber is 4% of the total mass of the third electromagnetic functional material and the gelling material, the graphite powder The mixing amount is 10% of the total mass of t...

Embodiment 2

[0048] This embodiment differs from Embodiment 1 only in that the electromagnetic functional materials and doping amounts of each layer are different. In this embodiment, the first electromagnetic functional material of the wave-transmitting layer is SiC fiber and mica sheet, the dosage of SiC fiber is 5% of the total mass of the first electromagnetic functional material and the gelling material, and the dosage of mica sheet is the first 11% of the total mass of electromagnetic functional materials and gelling materials; SiC fibers are prepared by precursor conversion method, and the resistivity is generally 10 6 Ω.cm or so; the average particle size of mica flakes is 120μm.

[0049] The second electromagnetic functional material of the wave-absorbing layer selects chopped carbon fiber, ferrite and graphite powder, the dosage of chopped carbon fiber is 3% of the total mass of the second electromagnetic functional material and the gelling material, and the dosage of ferrite is ...

Embodiment 3

[0053] This embodiment differs from Embodiment 1 and Embodiment 2 only in that the functional ingredients and dosage of each layer are different.

[0054] In this embodiment, the first electromagnetic functional material of the wave-transparent layer is SiC fibers and hollow microspheres, the dosage of SiC fibers is 3% of the total mass of the first electromagnetic functional material and the gelling material, and the dosage of hollow microspheres is 12% of the total mass of the first electromagnetic functional material and the gelling material.

[0055] The second electromagnetic functional material of the wave-absorbing layer is graphite powder, and the amount of graphite powder is 15% of the total mass of the second electromagnetic functional material and the gelling material.

[0056] The third electromagnetic functional material of the reflective layer is selected from steel fiber, conductive nickel powder and chopped carbon fiber, the amount of steel fiber is 5% of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com