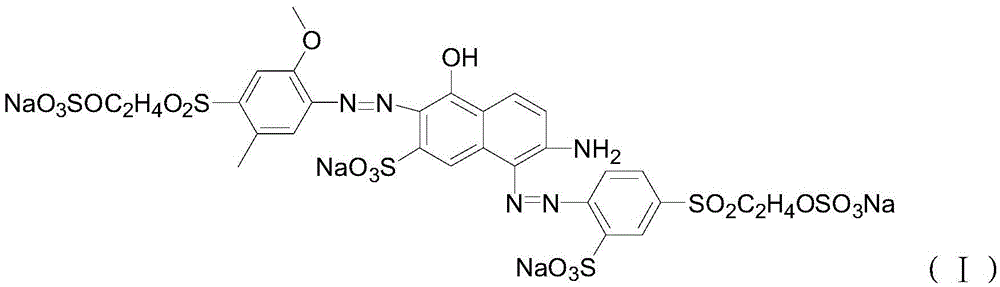

Active red dye preparation method

A technology of reactive red dye and sulfonated para-ester, which is applied in the field of preparation of reactive red dye, can solve the problems of low dye content, increased waste water, unfavorable environment, etc., to reduce salt content, reduce waste water volume, and improve environmental protection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

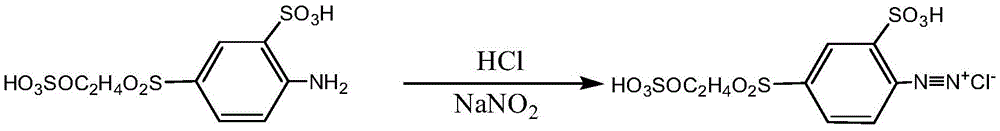

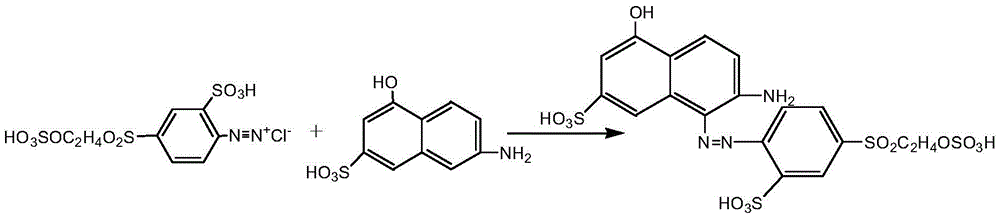

Method used

Image

Examples

Embodiment 1

[0035] (1) Put 2000kg of fuming sulfuric acid (containing 25% sulfur trioxide) in a 3000L sulfonation pot, and put 840kg of p-hydroxyethyl sulfone acetanilide into the sulfonation pot evenly in about 3 hours under stirring conditions, and feed During the process, keep the temperature ≤35°C. After the feeding is completed, use steam to slowly raise the temperature to about 80°C, use the heat of reaction to raise the temperature to 110°C, keep the temperature for reaction, and then raise the temperature to 130°C for reaction.

[0036] (2) After the reaction, use cold water to cool down to below 60°C, and then add water dropwise into the pot. The temperature is controlled not to exceed 60°C during the dropwise addition, and it takes about 3 hours. After adding water, raise the temperature to 98±1°C, and keep the temperature for 10 hours. , cooled to 25°C.

[0037] (3) Add 1000kg of bottom water to the dilution pot, start stirring, put in 1500kg of crushed ice, then put the sulfo...

Embodiment 2

[0044] (1) Put 2000kg of fuming sulfuric acid (containing 25% sulfur trioxide) in a 3000L sulfonation pot, and put 840kg of p-hydroxyethyl sulfone acetanilide into the sulfonation pot evenly in about 3 hours under stirring conditions, and feed During the process, keep the temperature ≤35°C. After the feeding is completed, use steam to slowly raise the temperature to about 80°C, use the heat of reaction to raise the temperature to 110°C, keep the temperature for reaction, and then raise the temperature to 130°C for reaction.

[0045] (2) After the reaction, use cold water to cool down to below 60°C, and then add water dropwise into the pot. The temperature is controlled not to exceed 60°C during the dropwise addition, and it takes about 3 hours. After adding water, raise the temperature to 98±1°C, and keep the temperature for 10 hours. , cooled to 25°C.

[0046] (3) Add 1000kg of bottom water to the dilution pot, start stirring, put in 1500kg of crushed ice, then put the sulfo...

Embodiment 3

[0053] (1) Put 2000kg of fuming sulfuric acid (containing 25% sulfur trioxide) in a 3000L sulfonation pot, and put 840kg of p-hydroxyethyl sulfone acetanilide into the sulfonation pot evenly in about 3 hours under stirring conditions, and feed Keep the temperature ≤35°C during the process. After the feeding is completed, use steam to slowly raise the temperature to about 80°C, use the heat of reaction to raise the temperature to 110°C, keep the temperature for reaction, and then raise the temperature to 130°C for reaction.

[0054] (2) After the reaction, use cold water to cool down to below 60°C, and then add water dropwise into the pot. The temperature is controlled not to exceed 60°C during the dropwise addition, and it takes about 3 hours. After adding water, raise the temperature to 98±1°C, and keep the temperature for 10 hours. , cooled to 25°C.

[0055] (3) Add 1000kg of bottom water to the dilution pot, start stirring, put in 1500kg of crushed ice, then put the sulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com