Single-component high-efficiency lightweight interior-wall insulation putty and preparation method thereof

A thermal insulation putty, a single-component technology, applied in the direction of filling slurry, etc., can solve the problems of insufficient safety in use, and achieve the effects of not easy to crack, high bonding strength, and convenient construction

Inactive Publication Date: 2016-04-27

CHONGQING XINGYU POLYMER PAINT

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The thermal insulation effect of this scheme largely depends on the foaming reaction between isocyanate and polyhydroxy polymer compound, which in turn depends on various conditions such as temperature and stirring; in addition, isocyanate is a highly toxic product, which is not safe enough to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

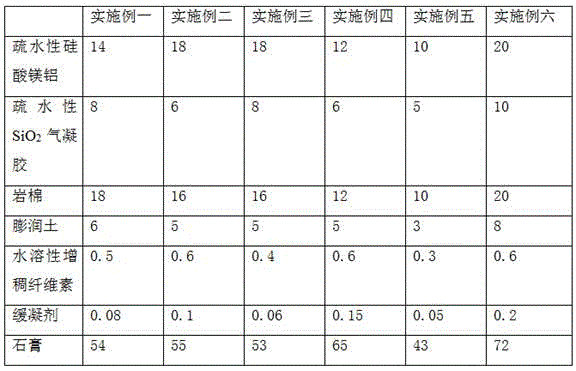

[0030] Embodiment one, embodiment two, embodiment four~embodiment six except that the component quality of table 1 is different, all the other are consistent with embodiment three.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

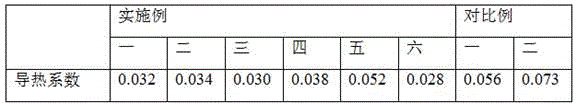

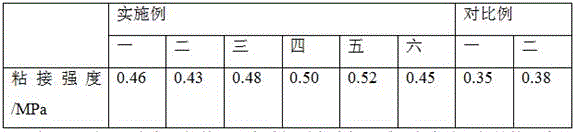

The invention discloses single-component high-efficiency lightweight interior-wall insulation putty, which comprises, by weight, 10-20 parts of hydrophobic aluminium-magnesium silicate, 5-10 parts of hydrophobic SiO2 aerogel, 10-20 parts of rock wool, 3-8 parts of bentonite, 0.3-0.6 part of water-soluble thickening cellulose, 0.05-0.2 part of a retarder and 43-72 parts of gypsum. The technical problem to be solved is to provide single-component high-efficiency lightweight interior-wall insulation putty which has low heat conductivity coefficient, good thermal insulation effect and high fire resistance rating and is convenient for construction and a preparation method thereof.

Description

technical field [0001] The invention relates to the field of thermal insulation building materials, in particular to a single-component high-efficiency lightweight interior wall thermal insulation putty and a preparation method thereof. Background technique [0002] In the field of construction, building thermal insulation is an important measure to achieve the strategic goal of sustainable development in my country. Considering the occupation of the area, etc., the external wall insulation system is the most widely used for building thermal insulation at present, but the construction procedure of the external wall insulation is complicated, especially for the thermal insulation transformation of some old buildings, due to the need to re-build scaffolding , and the difficulty of safety management, the opinions of the owners are often not unified. Compared with the external insulation renovation project, the implementation of the internal insulation renovation is more flexib...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D5/34

CPCC09D5/34

Inventor 季金苟谢方奎

Owner CHONGQING XINGYU POLYMER PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com