Treatment process for improving structure and performance of Al-Mg alloy

A treatment process and alloy structure technology, which is applied in the field of treatment process to improve the structure and performance of Al-Mg alloy, can solve the problems that it is difficult to completely analyze the influence of rare earth elements on the performance, and the addition of rare earth elements has a great influence, and achieve a large degree of distortion , low conductivity, high solid solution temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A treatment process for improving the microstructure and properties of an Al-Mg alloy, comprising the following steps:

[0023] (1) Ingredients: The raw material is borated industrial pure aluminum (99.7% mass fraction), the composition is: 99.29%Al, 0.004%B, 0.167%Si, 0.271%Fe, 0.055%Mg, 0.041%Cr, 0.0027% Ni, 0.033%Ti, the rest 0.071;

[0024] (2) Prepare Al-Mg alloy by conventional means;

[0025] (3) Solid solution: Al-Mg alloy is kept at 535°C for 5 hours. When the holding is over, it will be taken out of the box-type heat treatment furnace and immediately cooled with water at room temperature.

[0026] In the step (2), a well-type heat treatment furnace is used for smelting.

[0027] In the step (3), a box-type heat treatment furnace is used for solution treatment.

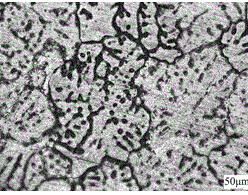

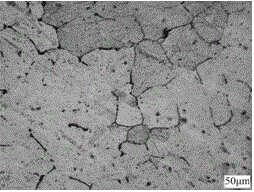

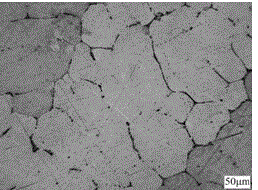

[0028] Using the above treatment process to improve the structure and properties of Al-Mg alloy, it can be obtained as follows Figure 1~Figure 4 The metallographic and microstructure observation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com