Heat neutron spectrum hybrid-positioning multi-flow-region fuel assembly and supercritical water reactor

A hybrid positioning and fuel assembly technology, which is applied in the field of nuclear reactors, can solve the problems of complex structural design and manufacturing difficulties of assemblies and cores, and achieve the effects of enhancing the axial structural design strength of assemblies, reducing structural design, and enhancing heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

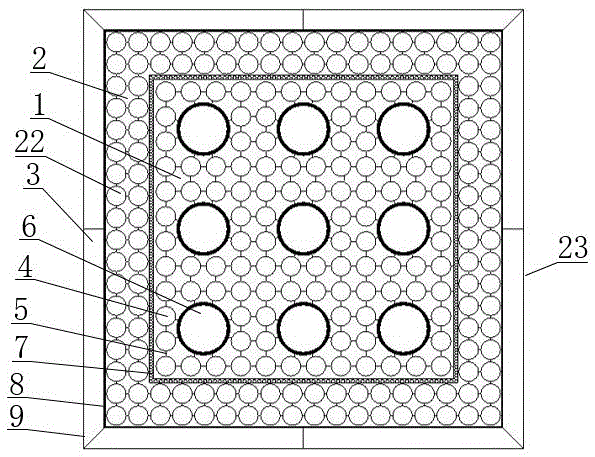

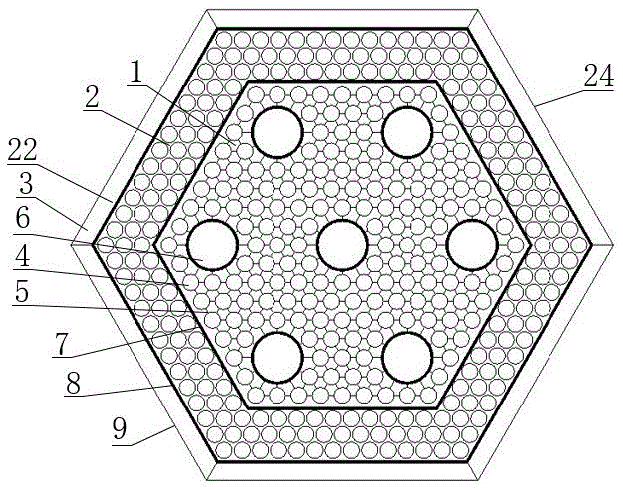

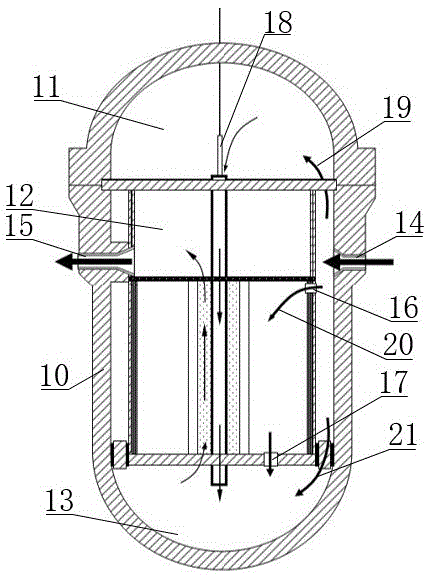

[0028] Such as figure 1 , figure 2 As shown, a thermal neutron spectrum mixed positioning multi-flow zone fuel assembly includes a heat insulation shroud 7 and a strong heat insulation assembly box 8 and an assembly grid 9 that are sequentially set outside the heat insulation shroud 7 in the radial direction. The inside of the heat enclosure 7 is the inflow zone 1, the middle flow zone 2 is between the heat insulation enclosure 7 and the strong heat insulation component box 8, and the outflow zone 3 is between the strong heat insulation component box 8 and the component grid 9, namely The interior of the fuel assembly radially includes an inner flow area 1, an intermediate flow area 2, and an outer flow area 3. The coolant inlet of the inner flow area 1 is located at the upper part of the inner flow area 1, and the cooling of the inner flow area 1 The agent outlet is located at the lower part of the inner flow area 1, the coolant inlet of the middle flow area 2 is located at...

Embodiment 2

[0036] Such as figure 1 As shown, the structure of the thermal neutron spectrum mixing and positioning multi-flow area fuel assembly is the same as that of Embodiment 1, and further, the thermal neutron spectrum mixing positioning multi-flow area fuel assembly is a square fuel assembly 23, and the fuel assembly adopts a fuel rod outside The diameter is 9.5 mm, and the fuel rods 4 in the internal flow area are arranged in a 12×12 square grid with a grid pitch of 12.2 mm. A total of 9 guide tubes 6 and 108 fuel rods are arranged in the internal flow area 1, and the grid frame 5 is used for positioning. Each guide tube 6 occupies 4 grid positions, the outer diameter of the guide tube 6 is 24.0 mm, and the wall thickness is 1.0 mm. The heat insulation shroud 7 between the inner flow area 1 and the middle flow area 2 has a thickness of 1.0mm. The fuel rods 22 in the middle flow area are arranged in a dense grid of 18×18 squares with a grid pitch of 10.6 mm. A total of 128 fuel rod...

Embodiment 3

[0040] The structure of the thermal neutron spectrum mixed positioning multi-flow zone fuel assembly is the same as that of embodiment 1, and further, such as figure 2 As shown, the fuel assembly in the thermal neutron spectrum mixing and positioning multi-flow area is a hexagonal fuel assembly 24, the outer diameter of the fuel rods is 9.5 mm, and the fuel rods 4 in the inner flow area are arranged in a triangular grid with a grid pitch of 12.6 mm. A total of 7 guide pipes 6 and 168 fuel rods are arranged in zone 1, and the grids 5 are used for positioning. Each guide tube 6 occupies 7 grid positions, the outer diameter of the guide tube 6 is 29.0 mm, and the wall thickness is 1.0 mm. The heat insulation shroud 7 between the inner flow area 1 and the middle flow area 2 has a thickness of 2.0 mm and a distance across sides of 191.4 mm. The fuel rods 22 in the intermediate flow area have a grid pitch of 10.6 mm, and a total of 216 fuel rods are arranged. The wires are used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com