Time-difference generator using two-pole balance

A time difference and generator technology, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve generator damage, generator fire damage, instrument and equipment damage, etc. problems, to achieve the effect of improving power generation efficiency, improving commerciality and reliability, and increasing power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

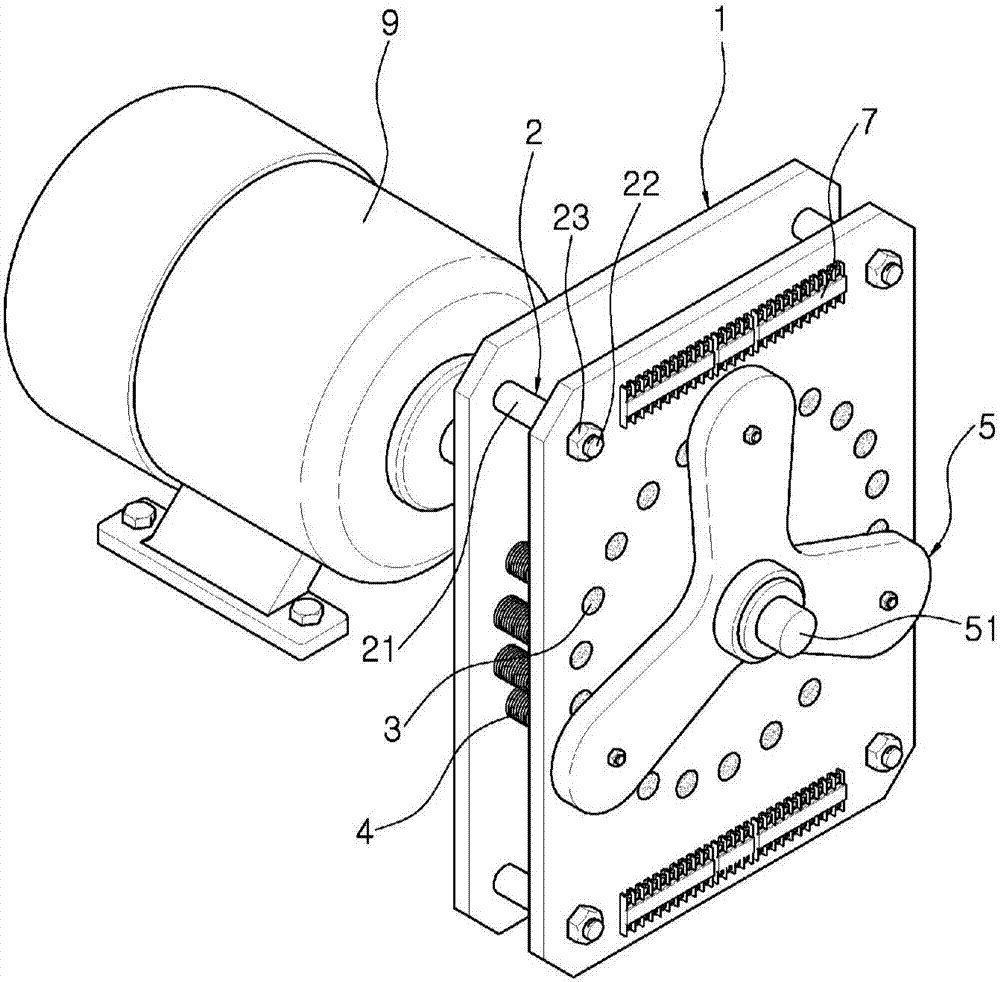

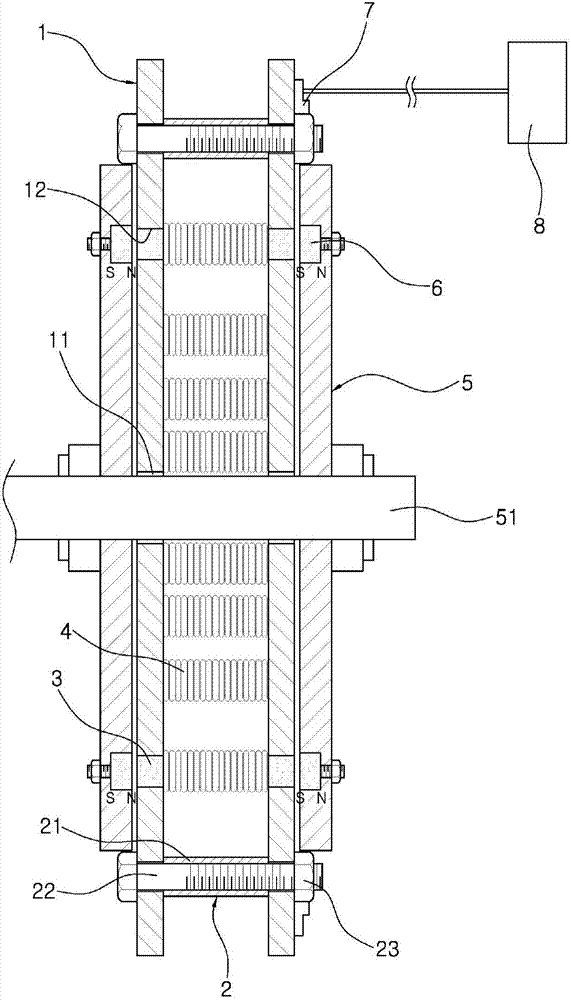

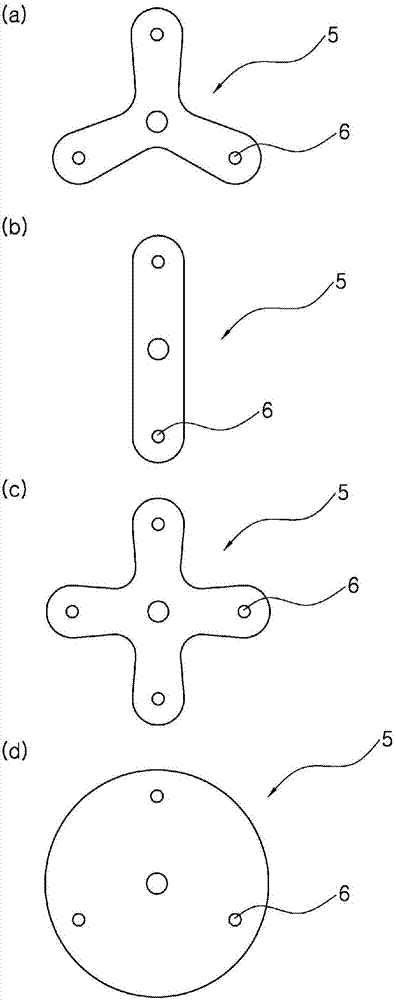

[0048] figure 1 is a perspective view of a generator according to an embodiment of the present invention, figure 2 is a sectional view of a generator according to an embodiment of the present invention, image 3 Parts (a) to (d) are front views showing various embodiments of the rotating plate for a rotor in the present invention, Figure 4 It is the front view of the fixed plate of the generator of another embodiment of the present invention, Figure 5 Parts (a) and (b) of (a) are exemplary front views of rotating plates for a plurality of rotors applied to another embodiment of the present invention.

[0049] Accordingly, the time-difference generator using two-pole balance of the present invention is characterized in that it includes: a pair of fixed plates 1, forming a rotating shaft passing hole 11 at the center point, and leavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com