Application and method for using medium-chain fatty glyceride as condensing agent in dropping capsule

A technology of medium-carbon chain fatty acid glyceride and caprylic capric acid glyceride, which is applied in the application field of medium-carbon chain fatty acid as a condensing agent in the preparation of dropping soft capsules or capsules, and can solve the problem of undiscovered medium-carbon chain fatty acid glyceride Use and other problems to achieve the effect of prolonging the service life, preventing the turbidity of the condensing agent, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

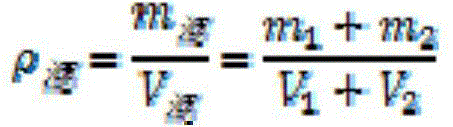

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 takes fat-soluble vitamins as the method for content dripping capsules

[0029] A method for dripping capsules, the method for dripping comprises the steps of:

[0030] (1) Pour glyceryl caprylate into the condensate storage tank of the capsule preparation machine, adjust its temperature to about 12°C, and set aside;

[0031] (2) Drop the content containing vitamin A, vitamin D, vitamin E, vitamin K and the capsule material into caprylic capric acid glyceride in the form of concentric column flow, and the residence time of the content in the condensing agent is 30s Left and right, molding to obtain prototype capsules;

[0032] (3) Take out the prototype capsule, initially filter out the grease on its surface, then place the capsule in ethyl acetate solvent at room temperature according to the weight ratio of the prototype capsule to ethyl acetate 1:2, and stir to remove the surface of the rough product. grease, repeat the above operation 2 times, and then...

Embodiment 2

[0033] Embodiment 2 takes menthol as the method for content drip capsule

[0034] A method for dripping capsules, the method for dripping comprises the steps of:

[0035] (1) Pour glyceryl caprylate into the condensate storage tank of the capsule preparation machine, adjust its temperature to about 12°C, and set aside;

[0036] (2) the content containing menthol is dropped in caprylic capric acid glyceride, and the residence time of described content in condensing agent is about 30s, and molding obtains prototype dropping pill;

[0037] (3) Take out the rudimentary dropping pills, preliminarily filter out the grease on its surface, then place the dropping pills in an ethanol solvent at room temperature according to the weight ratio of the rudimentary dropping pills to ethanol 1:3, and stir to remove the grease on the surface of the crude product. Grease, then take out described rudiment dropping pill and carry out follow-up operation.

Embodiment 3

[0038] Embodiment 3 drops the method for capsule with the content that contains fragrance material

[0039] A method for dripping capsules, the method for dripping comprises the steps of:

[0040] (1) Pour glyceryl caprylate into the condensate storage tank of the capsule preparation machine, adjust its temperature to about 12°C, and set aside;

[0041] (2) Drop the content containing ethyl lactate and ethyl acetate flavoring material into caprylic capric acid glyceride, and the residence time of the content in the condensing agent is about 30s, and the prototype soft capsule is obtained by molding;

[0042] (3) Take out the prototype soft capsule, preliminarily filter the grease on its surface, then place the capsule in an ethanol solvent at room temperature according to the weight ratio of the prototype capsule to ethanol 1:2, stir to remove the grease on the surface of the crude product, Then take out described rudimentary soft capsule and carry out follow-up operation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com