Waste gas adsorption treatment device and treatment method

A technology of adsorption treatment and treatment method, which is applied in the field of waste gas adsorption treatment devices, can solve problems such as personal safety and property safety threats, combustion or explosion accidents of waste gas adsorption treatment devices, etc., achieves strong fire and explosion protection performance, reduces explosion accidents, and reduces hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

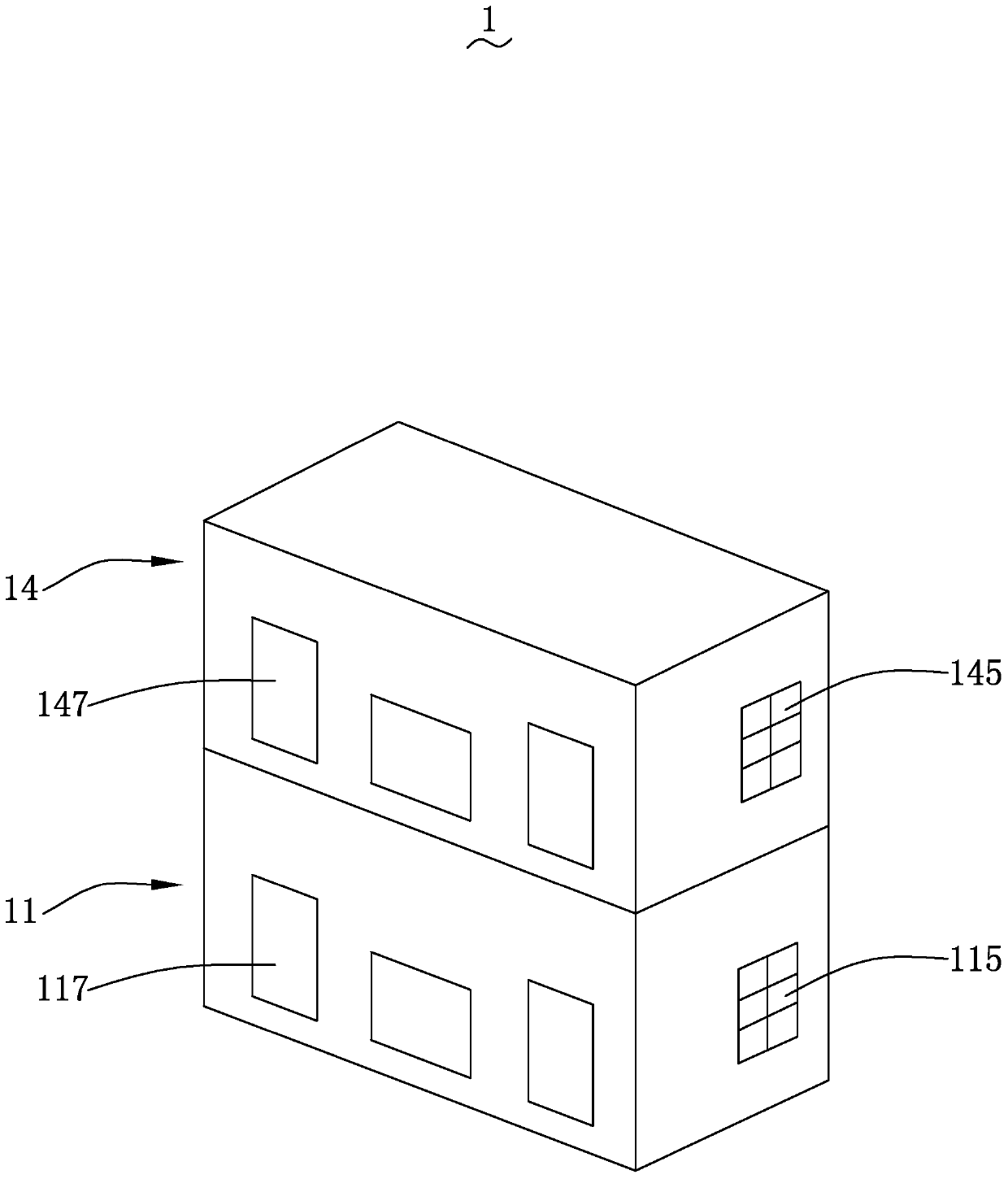

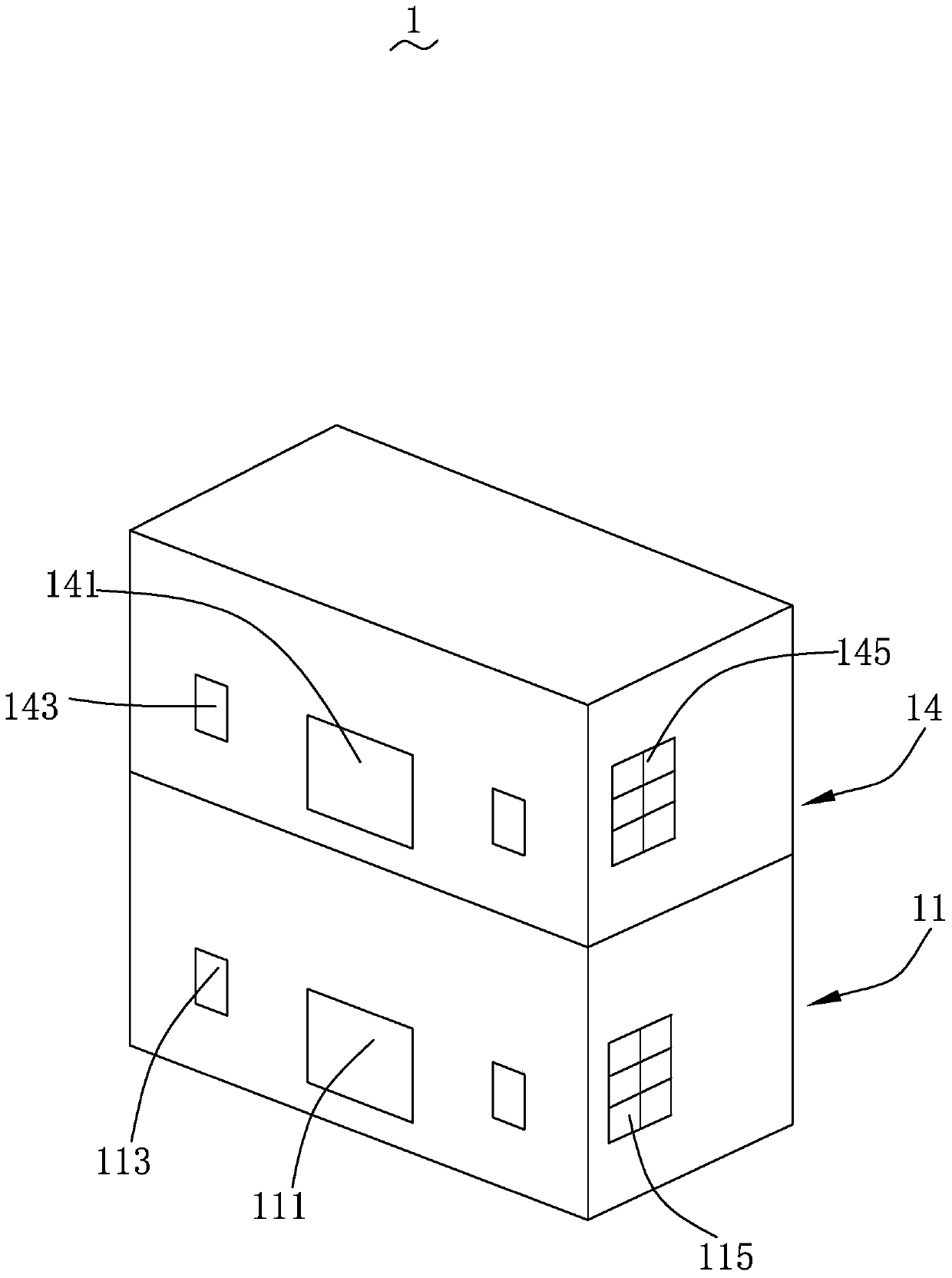

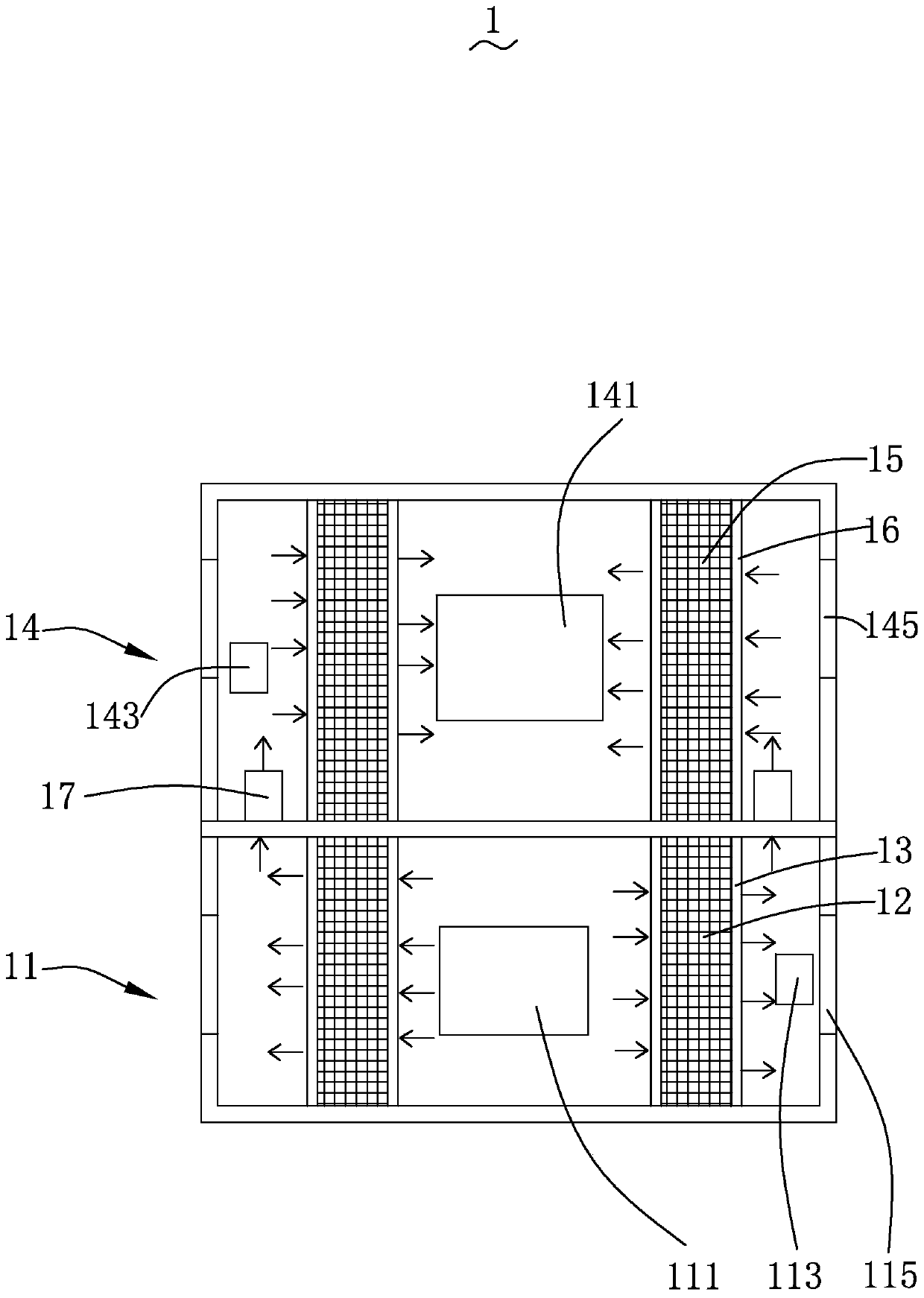

[0031] Please refer to Figure 1 to Figure 3 ,in figure 1 It is a schematic diagram of the three-dimensional structure of Embodiment 1 of the exhaust gas adsorption treatment device of the present invention; figure 2 It is a schematic three-dimensional structure diagram from another angle of Embodiment 1 of the exhaust gas adsorption treatment device of the present invention; image 3 It is a schematic diagram of gas flow in the adsorption process of Embodiment 1 of the exhaust gas adsorption treatment device of the present invention. The exhaust gas treatment device 1 includes a first adsorption box 11 , a primary flame retardant adsorber 12 , a primary support 13 , a second adsorption box 14 , a secondary flame retardant adsorber 15 , a secondary support 16 and a connecting pipe 17 .

[0032] The first adsorption box 11 and the second adsorption box 14 are stacked, and the first adsorption box 11 is located below the second adsorption box 14, and the first adsorption box ...

Embodiment 2

[0064] Please refer again Figure 6 to Figure 8 ,in Figure 6 It is a schematic diagram of the three-dimensional structure of Embodiment 2 of the exhaust gas adsorption treatment device of the present invention, Figure 7 It is a schematic diagram of the three-dimensional structure of another angle of Embodiment 2 of the exhaust gas adsorption treatment device of the present invention, Figure 8 It is a schematic diagram of gas flow in the adsorption process of Embodiment 2 of the exhaust gas adsorption treatment device of the present invention. The exhaust gas adsorption treatment device 2 includes a first adsorption box 21, a primary flame retardant adsorber 22, a primary support 23, a second adsorption box 24, a secondary flame retardant adsorber 25, a secondary support 26, a connecting pipe 27 and Electric damper 28.

[0065] Except that the number of the first desorption port 213 and the second desorption port 243 are different, and the electric air valve 28 is added, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com