Horizontal alkylation reactor with recycle acid feeding distribution tube

A technology of feeding distribution pipe and circulating acid, which is applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of unsatisfactory distribution effect and efficiency of circulating acid. and other problems, to achieve the effect of resisting shock, suppressing vibration, and mixing adequately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

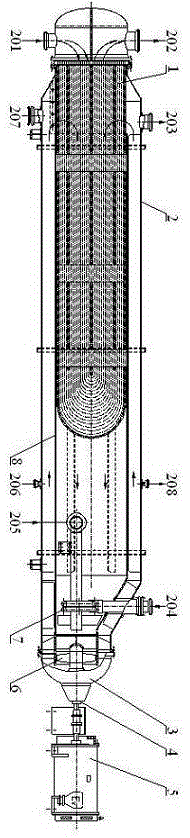

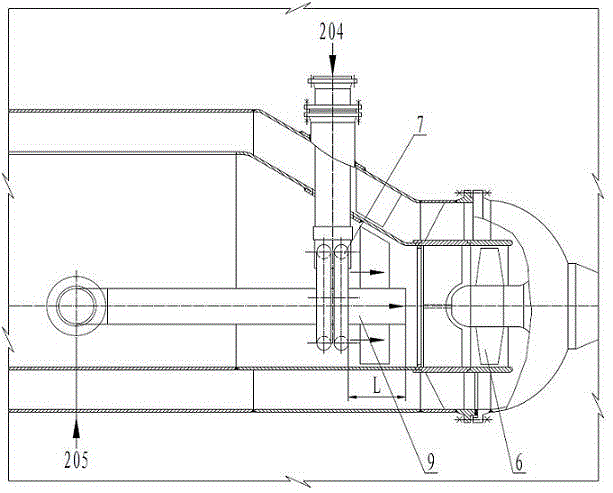

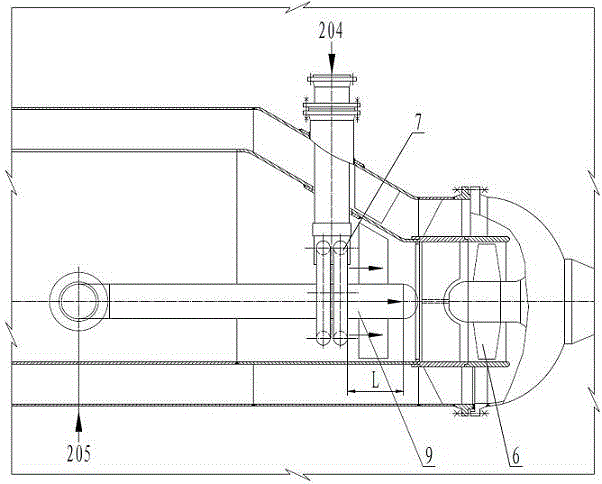

[0022] Such as figure 1 A horizontal alkylation reactor provided with a circulating acid feed distribution pipe, which includes a body 2, a guide plate 3, a mechanical seal system 4 and a motor 5, and the body 2 is respectively provided with a refrigerant inlet 201 and a refrigerant outlet 202, reaction product and acid outlet 203, raw material inlet 204, circulating acid inlet 205, waste acid outlet 206, mixture outlet 207, safety valve port 208; the body 2 is provided with an internal circulation sleeve 8, and the guide plate 3 at the rear end of the body 2 Connected with the motor 5 through the mechanical seal system 4; the inner circulation sleeve 8 is provided with a U-shaped tube heat exchange tube bundle 1, and the propeller 6 is provided between the end of the inner circulation sleeve 8 and the guide plate 3, and the main shaft of the propeller 6 is set It is connected to the mechanical seal system 4 and connected to the motor 5 through a coupling; the circulating acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com