Method for preparing trichlorosilane catalyst through hydrogenation dechlorination of silicon tetrachloride

A technology for hydrodechlorination and trichlorosilane, applied in the field of silicon purification, can solve the problems of high cost, complex catalyst preparation process, etc., and achieve the effects of solving storage, reducing pollution control equipment and operating costs, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

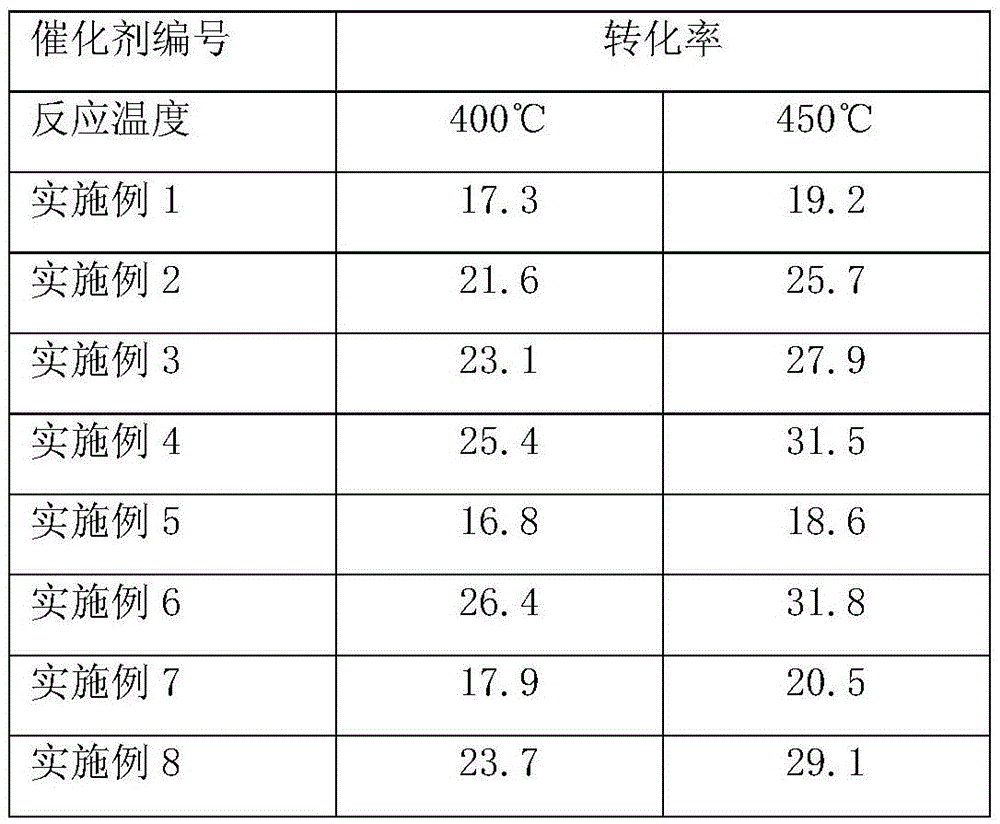

Embodiment 1

[0022] (1) Amorphous silicon aluminum after roasting, the specific surface area is 150m 2 / g, pore volume 0.7mL / g, silicon oxide content 5wt%, particle size 125μm, mixed with cuprous chloride, the mixing mass ratio is cuprous chloride:amorphous silicon aluminum=2.8:1.

[0023] (2) Under the protection of an inert gas, the above mixture was heated with a heating rate of 50°C / h, a calcination temperature of 450°C, and a constant temperature time of 30 minutes. After the constant temperature was completed, the temperature was naturally lowered to obtain a finished catalyst.

Embodiment 2

[0025] Others are the same as Example 1, the difference is that in step (2), the temperature during the roasting is 600 degrees centigrade, and the constant temperature is 30min.

Embodiment 3

[0027] (1) Amorphous silicon aluminum after roasting, the specific surface area is 500m 2 / g, pore volume 1.0mL / g, silicon oxide content 50wt%, particle size 200μm, mixed with cuprous chloride, the mixing mass ratio is cuprous chloride:amorphous silicon aluminum=4.0:1.

[0028] (2) Under the protection of an inert gas, the above mixture was heated with a heating rate of 100°C / h, a calcination temperature of 600°C, and a constant temperature time of 60 minutes. After the constant temperature was completed, the temperature was naturally lowered to obtain a finished catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com