Surface anisotropic topography processing method based on electronic dynamic regulation

An electronic dynamic control and anisotropic technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as complex processing technology, environmental pollution, and complex parameter adjustment, and achieve efficient processing methods and simplified processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

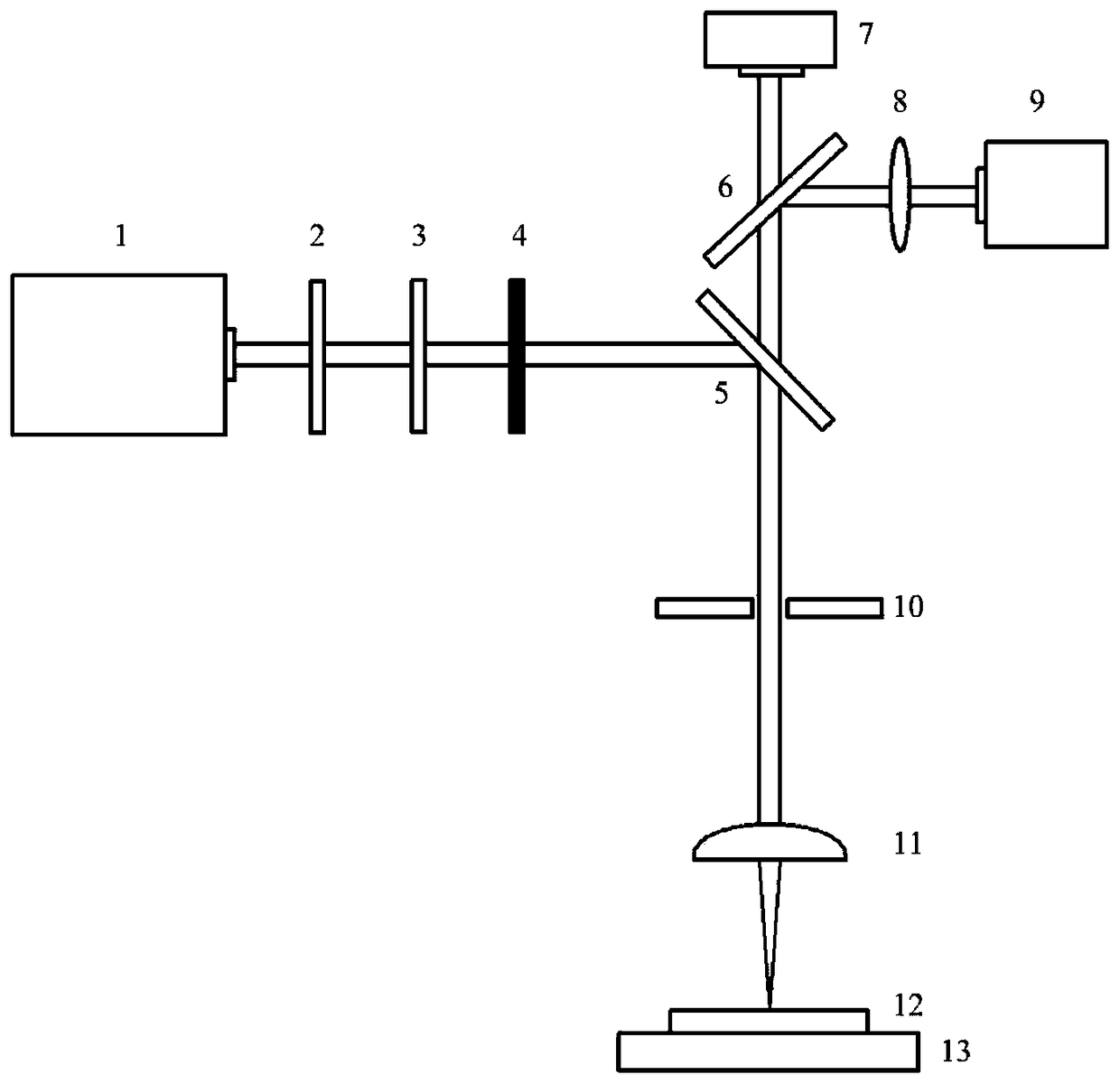

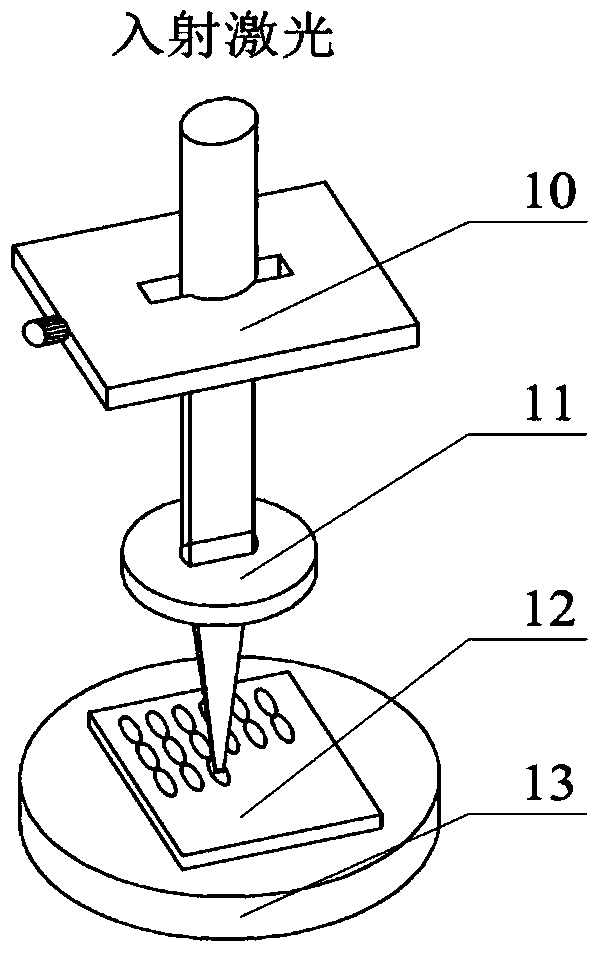

[0018] The method of surface anisotropic topography processing based on electronic dynamic control, the specific steps are as follows:

[0019] Step 1: Adjust the optical path of the femtosecond laser system to ensure that the laser can be vertically incident on the surface of the sample placed horizontally;

[0020] Step 2: Place the slit where the light path passes, adjust the position of the slit, and adjust the width of the slit to the desired size to ensure that the laser passes through the center of the slit vertically; the smaller the slit width, the more anisotropic the surface of the material obtained. The larger the ratio of the long and short axes of the anisotropic topography, the ratio of the long and short axes of the anisotropic topography can be continuously adjusted through the slit width;

[0021] Step 3: Carry out imaging with the help of imaging CCD9 and white lighting light source 7, observe the surface morphology and processing process of the processed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com