Preparation method of cellulose aerogels ball with controllable diameters

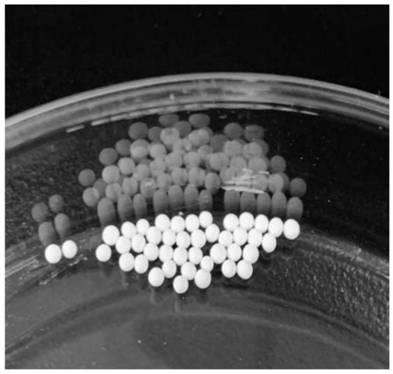

An aerogel ball and cellulose technology, which is applied in the field of preparation of cellulose aerogel balls, can solve the problem that the diameter of cellulose aerogel balls cannot be effectively controlled, the application range of cellulose aerogel balls is limited, and the disadvantages are great. Large-scale production application and other issues, to achieve the effect of improving application value, reducing preparation cost, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Preparation of cellulose solution:

[0042] Add 7g of NaOH and 12g of urea into 81g of cellulose powder aqueous suspension with a solid content of 1.2%, refrigerate at -8°C for 4 hours, take it out, and stir at room temperature until the cellulose powder dissolves into a transparent and viscous cellulose solution;

[0043] 2) Preparation of acidic coagulation bath:

[0044] Mix 100ml of ethyl acetate and 30ml of acetic acid, and stir evenly, as an acidic coagulation bath for later use;

[0045] 3) Preparation of cellulose gel balls:

[0046] The cellulose solution prepared in step 1) is transferred to the cylinder cavity of the dispensing needle of the dispensing device, and the needle of the dispensing needle is fixed on the iron stand, located at 2 cm above the acidic coagulation bath prepared in step 2), Specifically, the dispensing device includes a dispensing machine, a dispensing needle, and an air pump. The dispensing machine is used as a pressure controller...

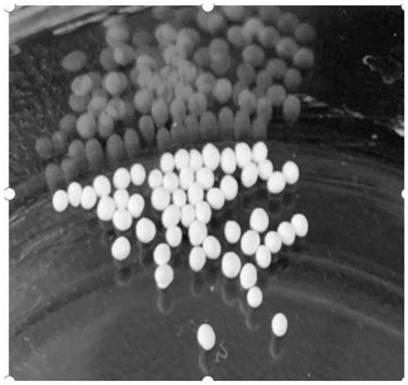

Embodiment 2

[0050] 1) Preparation of cellulose solution:

[0051] Add 7g of NaOH and 12g of urea into 81g of cellulose powder aqueous suspension with a solid content of 2%, refrigerate at -8°C for 6 hours, take it out, and stir at room temperature until the cellulose powder dissolves into a transparent and viscous cellulose solution;

[0052] 2) Preparation of acidic coagulation bath:

[0053] Mix 100ml of ethyl acetate and 30ml of hydrochloric acid with a mass fraction of 15%, and stir evenly, and use it as an acidic coagulation bath for subsequent use;

[0054] 3) Preparation of cellulose gel balls:

[0055] The cellulose solution prepared in step 1) is transferred to the cylinder cavity of the dispensing needle of the dispensing device, and the needle of the dispensing needle is fixed on the iron stand, located at 5 cm above the acidic coagulation bath prepared in step 2), Specifically, the dispensing device includes a dispensing machine, a dispensing needle, and an air pump. The dis...

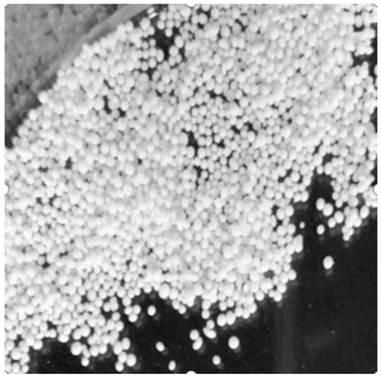

Embodiment 3

[0059] 1) Preparation of cellulose solution:

[0060] Add 7g of NaOH and 12g of urea into 81g of cellulose powder aqueous suspension with a solid content of 2.5%, refrigerate at -8°C for 8 hours, take it out, and stir at room temperature until the cellulose powder dissolves into a transparent and viscous cellulose solution;

[0061] 2) Preparation of acidic coagulation bath:

[0062] Mix 100ml of ethyl acetate and 30ml of sulfuric acid with a mass fraction of 10%, and stir evenly, and use it as an acidic coagulation bath for subsequent use;

[0063] 3) Preparation of cellulose gel balls:

[0064] The cellulose solution prepared in step 1) is transferred to the cylinder cavity of the dispensing needle of the dispensing device, and the needle of the dispensing needle is fixed on the iron stand, located at 5 cm above the acidic coagulation bath prepared in step 2), Specifically, the dispensing device includes a dispensing machine, a dispensing needle, and an air pump. The dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com