Technique for preparing ribitol by fermentation method

A preparation process, ribitol technology, applied in the direction of fermentation, microorganism-based methods, biochemical equipment and methods, etc., to achieve stable product quality, reduce glycerin content, and low content of by-products such as glycerin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

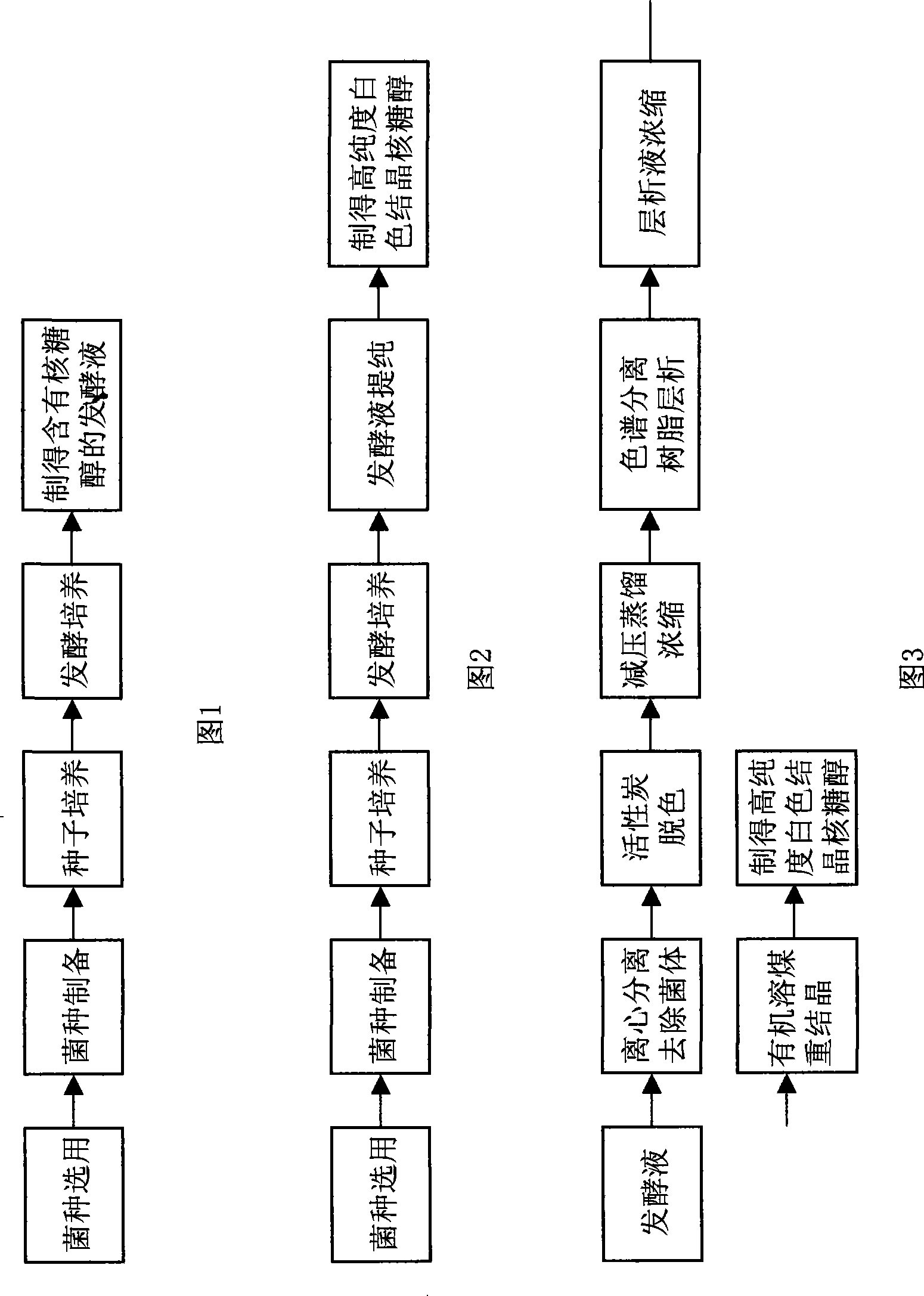

[0029] Embodiment 1: as attached figure 1 shown. Its process steps are:

[0030] (1) Strain selection. The hypertonic yeast Trichosporonoidesoedocephalis ATCC 16958 was selected

[0031] (2) Culture medium preparation.

[0032]

[0033] (3) Strain preparation. The strain was inoculated on a slant, cultured at 30°C±1°C for 4 days, and placed in a 4°C refrigerator for use.

[0034] (4) Seed cultivation.

[0035] Insert the bacterial strain after step 3 slant culture for 4 days into the seed culture solution. Aerobic cultivation was used for seed cultivation, using a 500mL Erlenmeyer shaker flask with a liquid volume of 100mL, a cultivation temperature of 30°C, a shaker rotation speed of 170rpm, and a cultivation time of 45h.

[0036] (5) Fermentation culture.

[0037] a. A 50L fermenter was used for fermentation culture, with a liquid volume of 30L, a tank pressure of 0.5MPa, a culture temperature of 30°C, and a pH of 5.0;

[0038] b. Fermentation method

[0039] The ...

Embodiment 2

[0042] Embodiment 2: as attached figure 1 shown. Its process steps are:

[0043] (1) Selection of strains. With embodiment 1.

[0044] (2) Culture medium preparation. With embodiment 1.

[0045] (3) Strain preparation. With embodiment 1.

[0046] (4) Seed cultivation. Same as implementation 1.

[0047] (5) Fermentation culture.

[0048] a. A 50L fermenter was used for fermentation culture, with a liquid volume of 30L, a tank pressure of 0.5MPa, a culture temperature of 30°C, and a pH of 5.0;

[0049] b. Fermentation method

[0050] Insert the seed culture solution prepared in step 4 into the fermentation medium at a volume ratio of 5%, control the aeration rate during the entire fermentation process to 1vvm, and control the stirring speed at 350rpm 30 hours before fermentation, and control the dissolved oxygen within the range of 65% to 95%. After 30 hours, the stirring speed is reduced to 100-200 rpm, and the dissolved oxygen is controlled at 5%-30%, that is, the s...

Embodiment 3

[0052] Embodiment 3: as attached figure 1 shown. Its process steps are:

[0053] (1) Selection of strains. With embodiment 1.

[0054] (2) Culture medium preparation. With embodiment 1.

[0055] (3) Strain preparation. With embodiment 1.

[0056] (4) Seed cultivation. Same as implementation 1.

[0057] (5) Fermentation culture.

[0058] a. Insert the seed culture solution into the fermentation medium at a volume ratio of 5%, control the ventilation rate to 1vvm during the whole fermentation process, and the stirring speed is 350rpm 30 hours before fermentation, and reduce the fermentation speed to 100-200rpm after 30 hours , so that dissolved oxygen is controlled at 5% to 30%, that is, the staged stirring fermentation method of the present invention is adopted. At the same time, under the premise that the total amount of glucose in the fermentation process is 20%, the glucose concentration is controlled at 5% to 10% in the first 30 hours, and the remaining glucose is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com