A kind of bamboo beam dry heat treatment method

A technology of dry heat treatment and bamboo beams, which is applied in the direction of wood heat treatment, wood treatment, wood treatment details, etc., can solve the problems of recombined bamboo dimensional stability, limited improvement of mildew resistance, difficulty in ensuring airtightness, and low steam treatment temperature, etc., to achieve Guarantee airtightness, reduce corrosion, and reduce the effect of acid gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

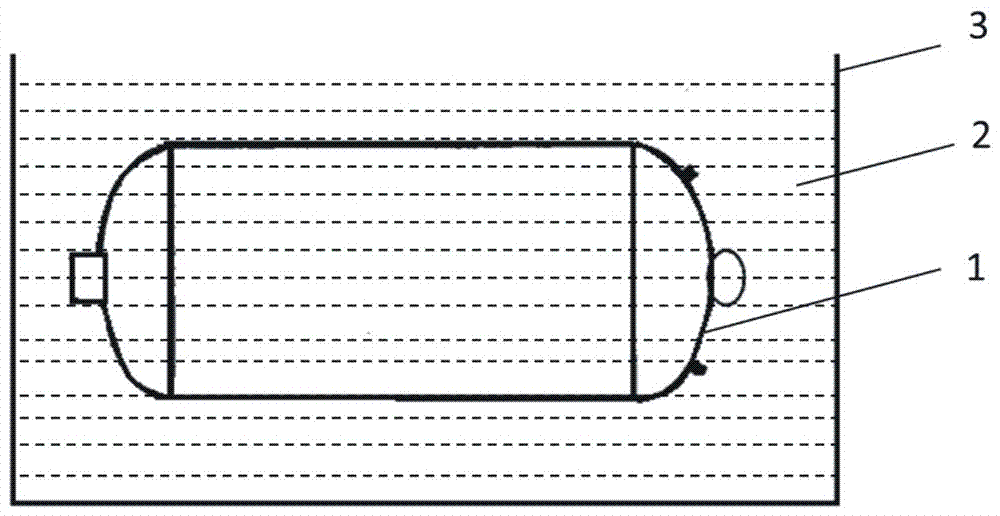

[0015] The equipment used in the bamboo bundle heat treatment equipment of the present invention comprises a pressure tank (1) and an oil pool (3), comprising the following steps: (1) preparation of bamboo bundles, (2) drying of bamboo bundles, (3) heat treatment of bamboo bundles, (4) ) Bamboo beam balance treatment:

[0016] (1) Bamboo bundle preparation:

[0017] After the raw bamboo is processed into bamboo strips with a thickness of 5 mm, it is decomposed into bamboo bundles with a diameter of 1.5 mm fiber bundles by using a decomposer;

[0018] (2) Bamboo bunch drying

[0019] The equipment used for drying the bamboo bundles described in step (1) is a mesh belt dryer, the drying temperature is 90°C, and the moisture content of the bamboo bundles after drying is 10%;

[0020] (3) Bamboo bundle heat treatment

[0021] After the step (2) is dried, the bamboo bundles are heated to 100°C with a mesh belt dryer, put into the pressure tank (1), and after closing the pressure...

Embodiment 2

[0025] The equipment used in the bamboo bundle heat treatment equipment of the present invention comprises a pressure tank (1) and an oil pool (3), comprising the following steps: (1) preparation of bamboo bundles, (2) drying of bamboo bundles, (3) heat treatment of bamboo bundles, (4) ) Bamboo beam balance treatment:

[0026] (2) Bamboo bundle preparation:

[0027] After the raw bamboo is processed into bamboo strips with a thickness of 3 mm, it is decomposed into bamboo bundles with a diameter of 3 mm fiber bundles by using a decomposer;

[0028] (2) Bamboo bunch drying

[0029] The equipment used for drying the bamboo bundles described in step (1) is a mesh belt dryer, the drying temperature is 100°C, and the moisture content of the bamboo bundles after drying is 10%;

[0030] (3) Bamboo bundle heat treatment

[0031] Put the dried bamboo bundles in step (2) into the pressure tank (1), and after closing the pressure tank door, put the bamboo bundles together with the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com