Bag tearing device and bag tearing method

A technology of breaking bags and driving devices, which is applied in the directions of packaging, transportation and packaging, and unsealing of packaged objects. It can solve the problems of blockage and entanglement of crushing equipment, inability to realize biochemical reactions, and high failure rate of equipment, so as to reduce equipment failure and improve predictability. High processing efficiency, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

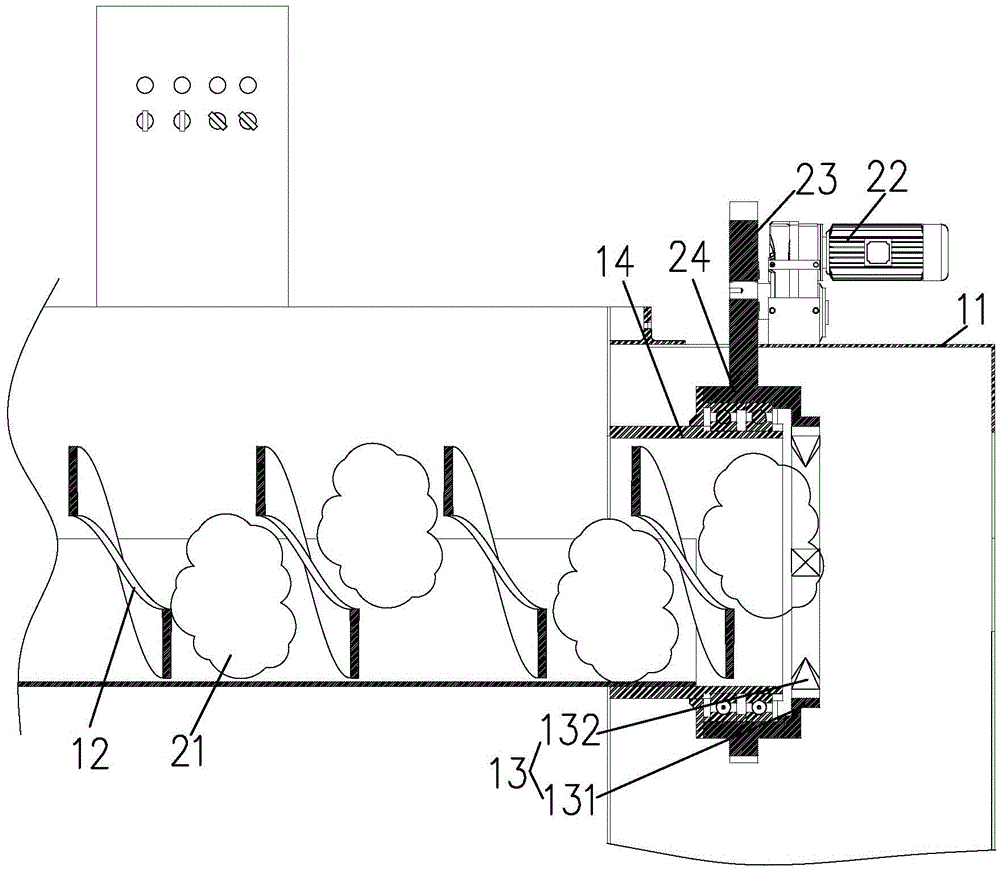

[0013] Such as figure 1 Shown is a bag-breaking device of the present invention, comprising a casing 11, a screw conveying device 12, and a bag-breaking cutter 13. The casing 11 is provided with a feed port and a discharge port, and the screw conveying device 12 and the bag-breaking cutter 13 are all provided with In the casing 11, the screw conveying device 12 is connected with a driving device, and the bag breaking cutter 13 includes a cutter driving device, a deceleration device, a mounting disc 131 and several cutter bodies 132, the mounting disc 131 is annular, and several cutter bodies 132 are along the The circumferential direction is evenly arranged and fixed on the inner wall of the mounting plate 131. The tool mounting frame 14 is fixed in the casing 11. The tool mounting frame 14 is in the shape of a ring. A driving gear 23 is fixed on the output shaft of the driving gear 23, and the driven gear 24 meshed with the driving gear 23 is installed on the tool mounting fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com