Antiskid damping sole material and preparation method thereof

A sole material, the technology of rare earth butadiene, applied in the field of polymer composite materials, can solve the problems of human injury, foot discomfort, slipping and even falling, and achieve the effect of good anti-skid performance, excellent impact resistance and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

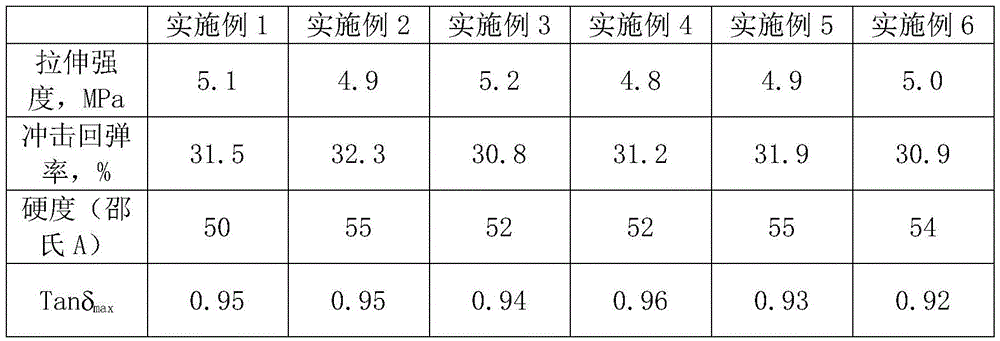

Examples

Embodiment 1

[0033] A kind of anti-slip shock-absorbing PVC shoe sole material, by weight, comprises the following components:

[0034] 30 parts of PVC resin, 10 parts of rare earth butadiene rubber,

[0035] 5 parts of natural rubber, 3 parts of wollastonite,

[0036] 2 parts of zinc stearate, 1 part of hollow glass microspheres,

[0037] 1 part foaming agent, 2 parts active agent,

[0038] Accelerator 0.5 parts, vulcanizing agent 0.5 parts.

[0039] Its preparation method comprises the following steps:

[0040] Add PVC resin, rare earth butadiene rubber, natural rubber, foaming agent, and coupling agent to the open mill and knead for 2 minutes at 80°C, add wollastonite, zinc stearate, hollow glass microspheres, and promote and vulcanizing agent, the temperature was raised to 100°C, and the kneading was continued for 5 minutes. After the kneading was uniform, the sheet was produced, and after being placed at room temperature for 12 hours, it was molded and vulcanized on a flat vulcani...

Embodiment 2

[0042] A kind of anti-slip shock-absorbing PVC shoe sole material, by weight, comprises the following components:

[0043] 60 parts of PVC resin, 15 parts of rare earth butadiene rubber,

[0044] 12 parts of natural rubber, 6 parts of wollastonite,

[0045] 5 parts of zinc stearate, 2 parts of hollow glass microspheres,

[0046] 2 parts of foaming agent, 3 parts of active agent,

[0047] Accelerator 1 part, vulcanizing agent 1.5 parts.

[0048] Its preparation method comprises the following steps:

[0049] Add PVC resin, rare earth butadiene rubber, natural rubber, foaming agent, and coupling agent to the open mill and knead for 5 minutes at 100°C, add wollastonite, zinc stearate, hollow glass microspheres, and promote and vulcanizing agent, the temperature was raised to 120°C, and the kneading was continued for 10 minutes. After kneading evenly, the sheet was produced, and after being placed at room temperature for 24 hours, it was molded and vulcanized on a flat vulcaniz...

Embodiment 3

[0051] A kind of anti-slip shock-absorbing PVC shoe sole material, by weight, comprises the following components:

[0052] 35 parts of PVC resin, 11 parts of rare earth butadiene rubber,

[0053] 7 parts of natural rubber, 4 parts of wollastonite,

[0054] 3 parts of zinc stearate, 1.2 parts of hollow glass microspheres,

[0055] 1.2 parts of blowing agent, 2.2 parts of active agent,

[0056] Accelerator 0.6 parts, vulcanizing agent 0.7 parts.

[0057] Its preparation method comprises the following steps:

[0058] Add PVC resin, rare earth butadiene rubber, natural rubber, foaming agent, and coupling agent to the open mill and knead for 3 minutes at 85°C, add wollastonite, zinc stearate, hollow glass microspheres, and promote and vulcanizing agent, the temperature was raised to 105°C, and the kneading was continued for 6 minutes. After the kneading was uniform, the sheet was released, and after being placed at room temperature for 14 hours, it was molded and vulcanized on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com