Biodegradable mulch and preparation method thereof

A technology of biodegradation and mulching, which is applied in the field of film materials, can solve the problems of difficulty in meeting the requirements of crops with long growth cycles and fast degradation speed, and achieve excellent biodegradability and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a biodegradable mulch film, comprising the following steps:

[0035] The raw materials are sequentially melt-blended, granulated and blow-molded to obtain a biodegradable mulch film;

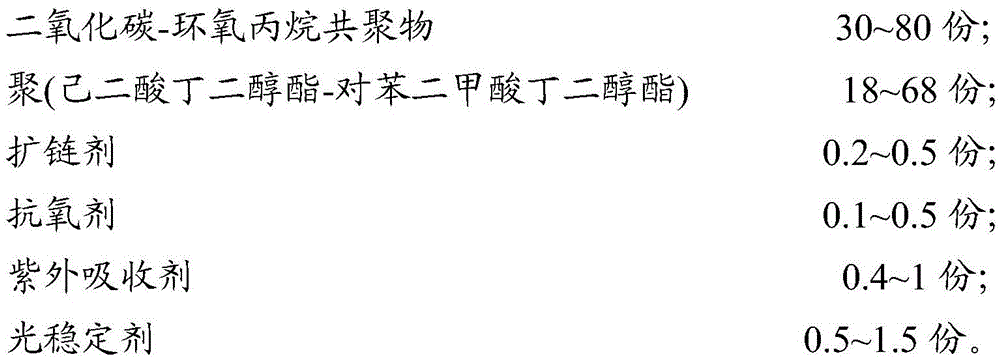

[0036] The raw materials include 30 to 80 parts by weight of carbon dioxide-propylene oxide copolymer, 18 to 68 parts by weight of poly(butylene adipate-butylene terephthalate), 0.2 to 0.5 parts by weight of Chain agent, 0.1-0.5 parts by weight of antioxidant, 0.4-1 parts by weight of ultraviolet absorber and 0.5-1.5 parts by weight of light stabilizer.

[0037] In the preparation method provided by the invention, the raw materials are first melt-blended and granulated, and the raw materials include carbon dioxide-propylene oxide copolymer, poly(butylene adipate-butylene terephthalate), Chain extenders, antioxidants, UV absorbers and light stabilizers. In the present invention, the content of the carbon dioxide-propylene oxide copolymer in t...

Embodiment 1

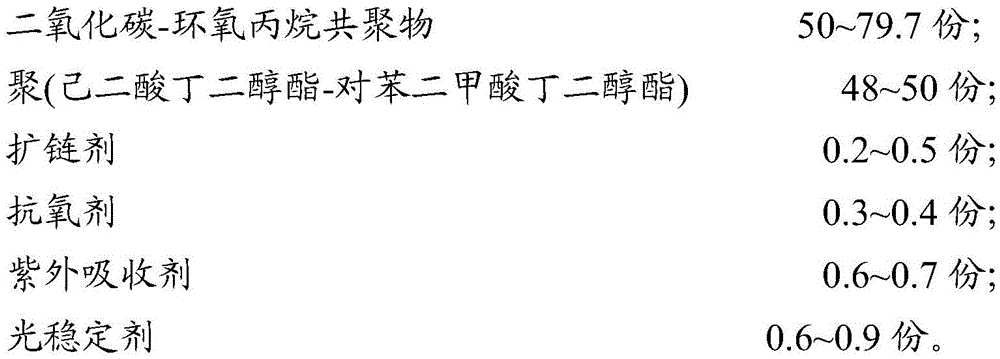

[0043] The melt index of 48 parts by weight is poly(butylene adipate-butylene terephthalate) of 3.5g / 10min, the melt index of 50 parts by weight is the carbon dioxide-propylene oxide of 0.5g / 10min Copolymer, 0.3 parts by weight antioxidant 1135, 0.3 parts by weight UV absorber 571, 0.3 parts by weight UV absorber 765, 0.3 parts by weight light stabilizer 944, 0.3 parts by weight light stabilizer 622, 0.3 parts by weight light stabilizer 770 Mix homogeneously with the BASF epoxy chain extender 4370 of 0.2 parts by weight in the mixer, then add the obtained mixture into a twin-screw granulator and granulate to obtain plastic particles; in the granulation process, the twin-screw granulator The temperature in the first zone is 140°C, the temperature in the second zone is 165°C, the temperature in the third zone is 180°C, the temperature in the fourth zone is 190°C, the temperature in the fifth zone is 195°C, the temperature in the sixth zone is 195°C, and the temperature in the sev...

Embodiment 2

[0046] The melt index of 68 parts by weight is the poly(butylene adipate-butylene terephthalate) of 3.0g / 10min, the melt index of 30 parts by weight is the carbon dioxide-propylene oxide of 0.5g / 10min Copolymer, 0.3 parts by weight antioxidant 1135, 0.3 parts by weight UV absorber 571, 0.3 parts by weight UV absorber 765, 0.3 parts by weight light stabilizer 944, 0.3 parts by weight light stabilizer 622, 0.3 parts by weight light stabilizer 770 Mix homogeneously with the BASF epoxy chain extender 4370 of 0.2 parts by weight in the mixer, then add the obtained mixture into a twin-screw granulator and granulate to obtain plastic particles; in the granulation process, the twin-screw granulator The temperature in the first zone is 140°C, the temperature in the second zone is 165°C, the temperature in the third zone is 185°C, the temperature in the fourth zone is 195°C, the temperature in the fifth zone is 195°C, the temperature in the sixth zone is 200°C, and the temperature in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com