Temperature change film deposition system

A technology of thin film deposition and deposition equipment, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of complex cavity switching operation and temperature change, so as to improve reaction efficiency, accelerate cooling, and avoid The effect of manual manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

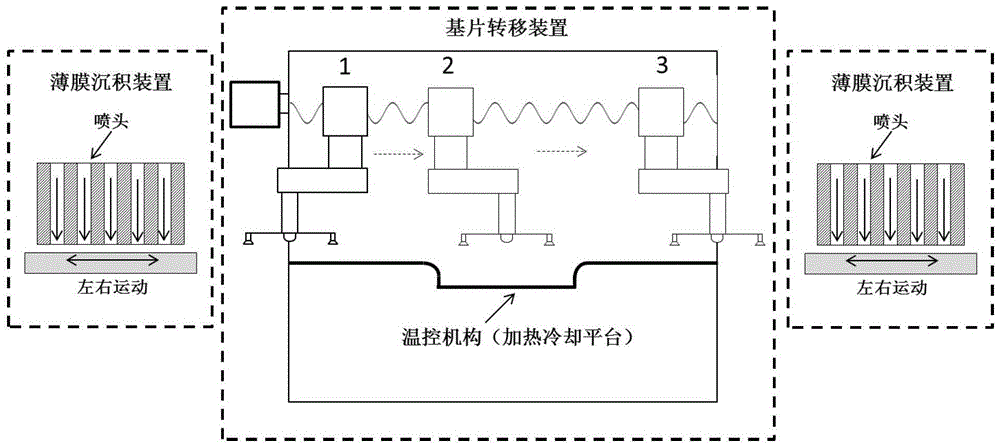

[0031] A variable temperature thin film deposition system, comprising two deposition devices and a substrate transfer device, the two deposition devices are at both ends of the substrate transfer device, such as figure 1 shown. The plurality of deposition devices have a substrate temperature control mechanism for respectively maintaining a constant temperature of the substrate carrying platform.

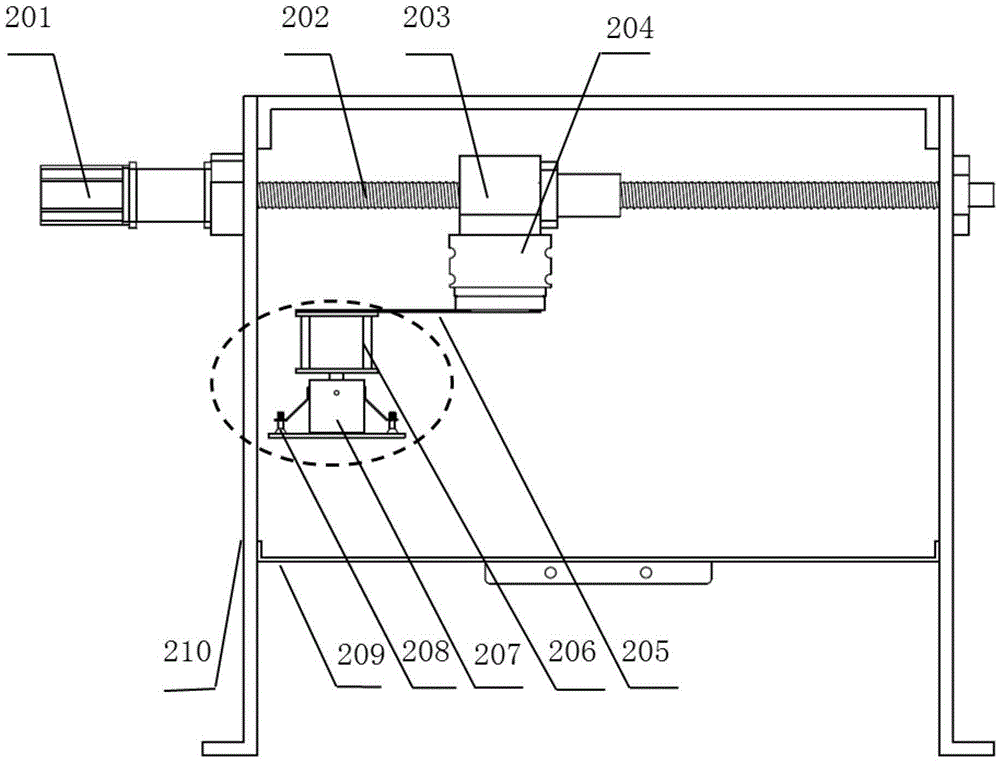

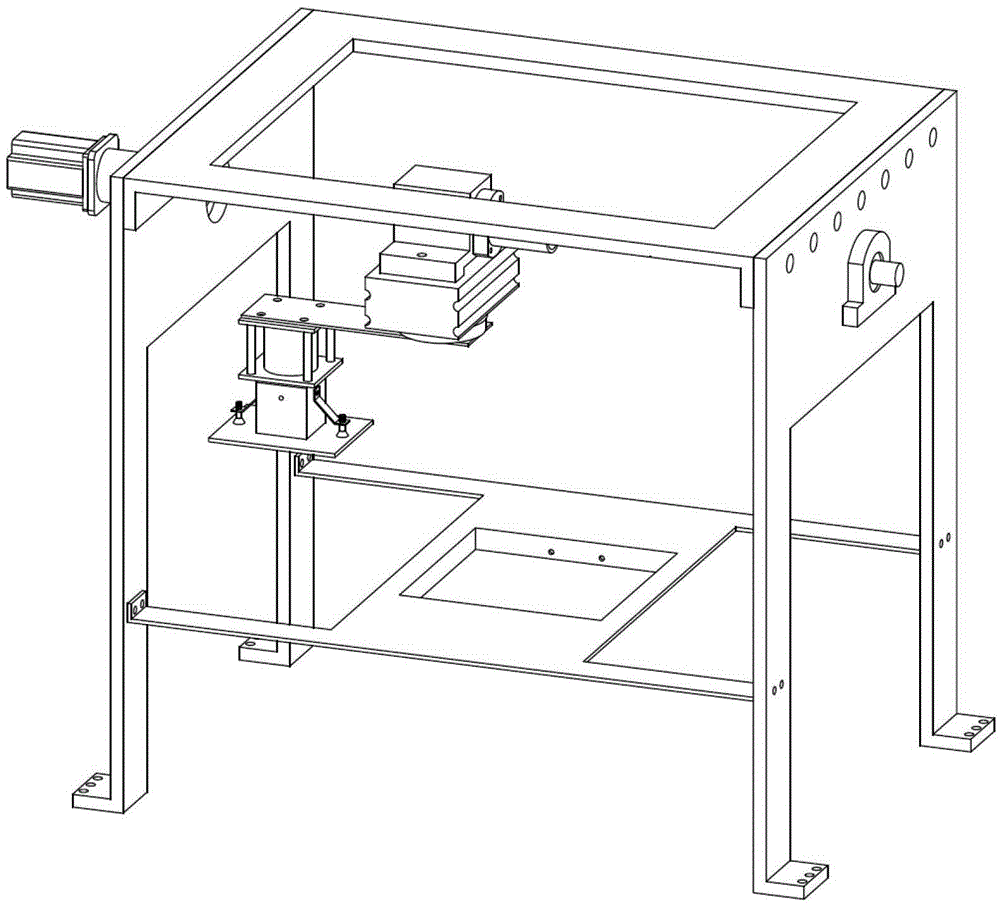

[0032] The substrate transfer device, such as figure 2 201 is a stepping motor, 202 is a ball screw, 203 is a workbench, 204 is a rotating cylinder, that is, a rotating mechanism, 205 is a mechanical arm, 206 is a telescopic cylinder, that is, a lifting mechanism, 207 is an inert gas nozzle, 208 It is a vacuum adsorption device, that is, a grabbing device, 209 is a cooling and heating platform, and 210 is a supporting frame.

[0033]The supporting frame 210 is composed of three steel plates, which are used to support and install the stepper motor and the ball screw, and fix the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com