Method for preparing regeneration lines for net body

The technology of body net and net wire is applied in the field of preparation of recycled wire for body net, which can solve the problems of potential safety hazards, poor strength of polyethylene monofilament, poor strength of body net wire and poor fishing performance, etc., so as to improve safety, The effect of improved durability and safety, and significant advantages in breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

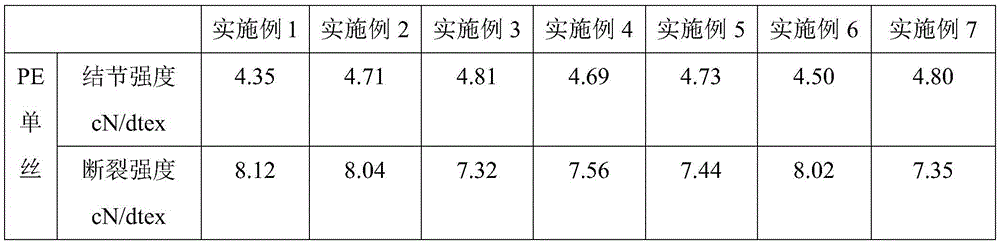

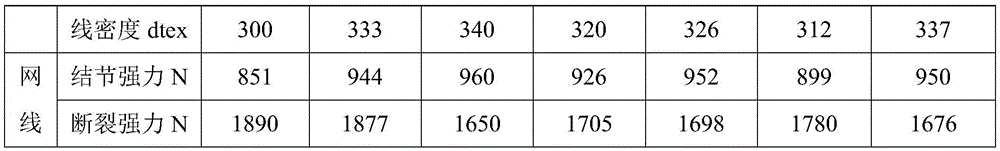

[0032] A preparation method for a regenerated thread for a body net, comprising the following steps:

[0033] (1) prepare materials according to the raw material components described in table 1 and table 2;

[0034] (2) Preparation of anti-aging masterbatch: mix HDPE regenerated pellets and pigments, and carry out twin-screw extrusion granulation at 220-250°C. The aspect ratio of the twin-screw extruder is 42, and the speed is 50-80r / min, the obtained masterbatch is dried in an oven at 70-100°C for 12-24h;

[0035] (3) Coloring: Stir and mix the MMWPE pellets, turpentine and the anti-aging masterbatch obtained in step (2) for 1600s to 5400s;

[0036] (4) Extrusion, cooling and pre-drawing: Put the colored MMWPE pellets obtained in step (3) into a single-screw extruder for melt extrusion. The temperature control ranges of Zone III and Zone IV are 318.0°C-321.0°C, 334.8°C-336°C, 349.5°C-351.5°C, 346.8°C-347.9°C respectively. The first drafting roller pre-draws, the cooling wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Lay length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com