Prefabricated sandwich thermal-insulation laminated wallboard and manufacturing method

A technology of prefabricated wall panels and manufacturing methods, applied in the direction of building components, buildings, building structures, etc., can solve the problems of reliability and product quality adverse effects, thermal insulation boards are easily damaged, and pouring process is troublesome, so as to avoid wall Plate cooling and heat bridge, eliminating potential safety hazards, and high production reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

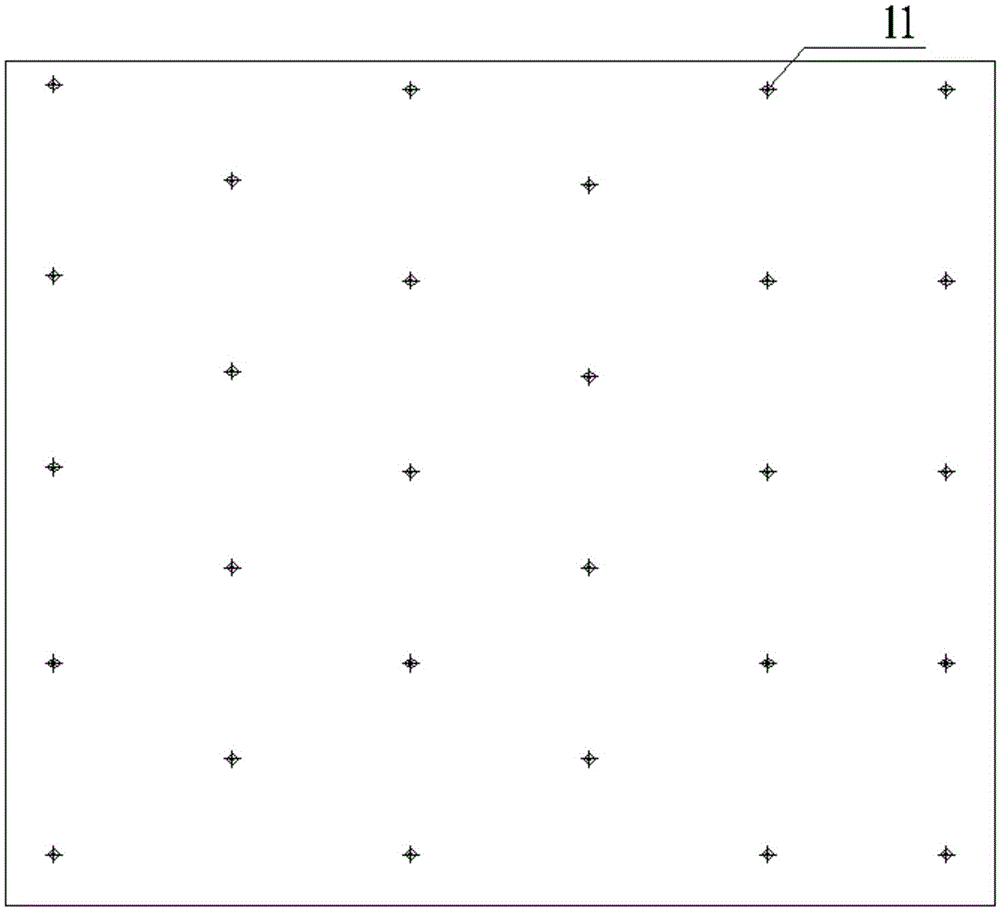

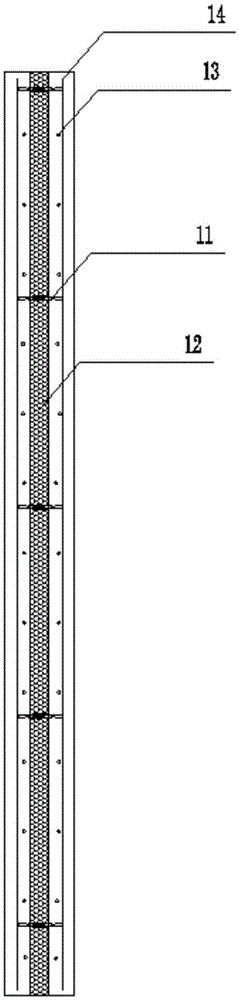

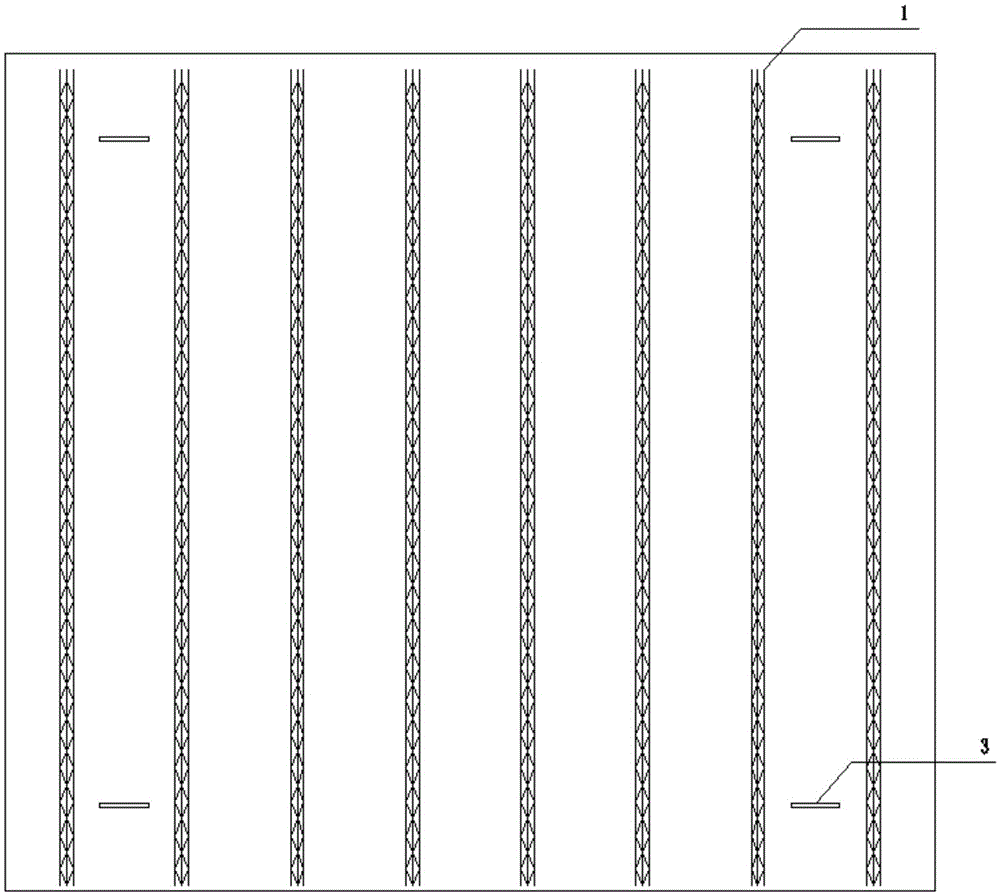

[0045] see Figure 3-Figure 11 , a kind of prefabricated sandwich thermal insulation laminated wallboard, comprising inner and outer layer prefabricated wallboards and an insulation layer 2 between them, and an insulation connector; The planar grid is poured as a skeleton; the insulation connectors are pre-embedded through the inner and outer prefabricated wall panels and the insulation layer 2; the insulation layer 2 is a foam insulation material, poured in the inner and outer layers between prefabricated wall panels.

[0046] The thermal insulation layer 2 is any one of foam thermal insulation materials such as polyurethane, phenolic, foamed cement, foamed glass, and polystyrene resin.

[0047] The thickness of the thermal insulation layer 2 is 30-200mm.

[0048] see Figure 4 , the heat preservation connector is made of stainless steel, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com