Pipe conveying device of natural gas hydrate

A natural gas and hydrate technology, applied in wellbore/well components, construction, production fluids, etc., can solve the problems of no large-scale natural gas hydrate commercial exploitation practice, changeable seabed environment, etc., to ensure operation continuity and difficult The effect of damage and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

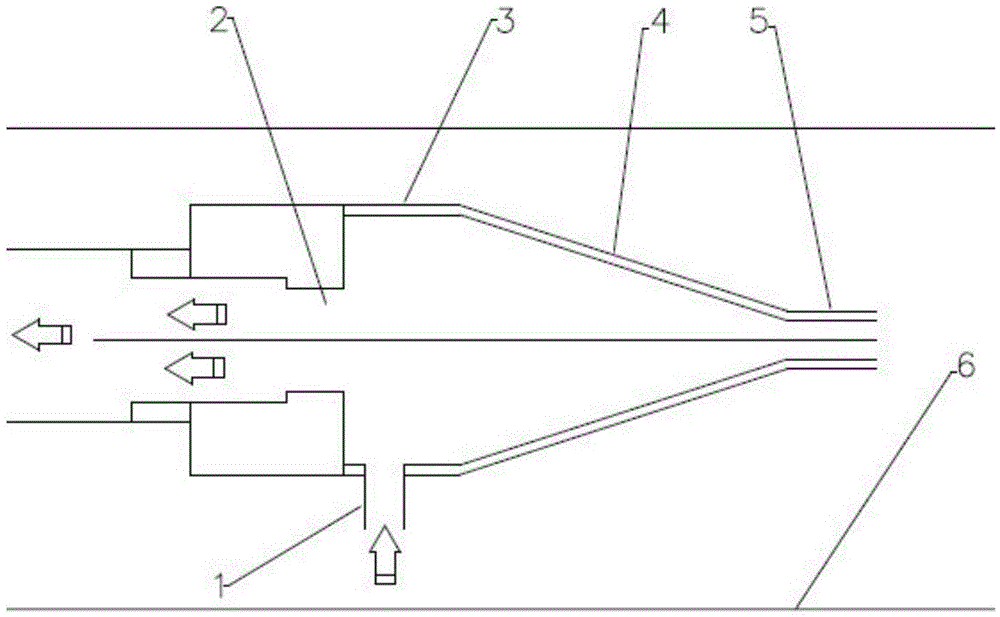

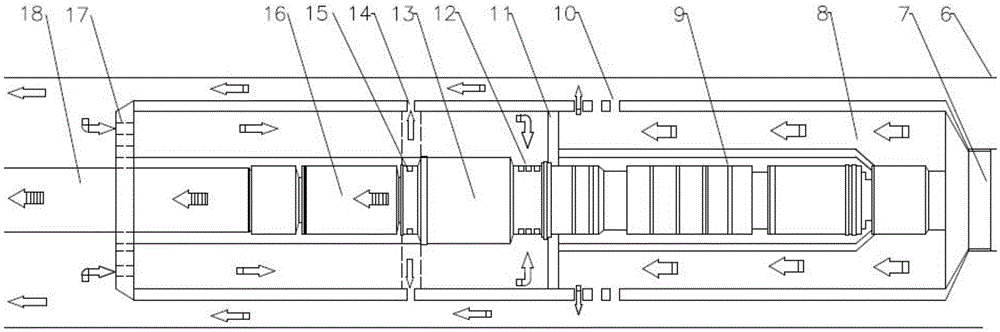

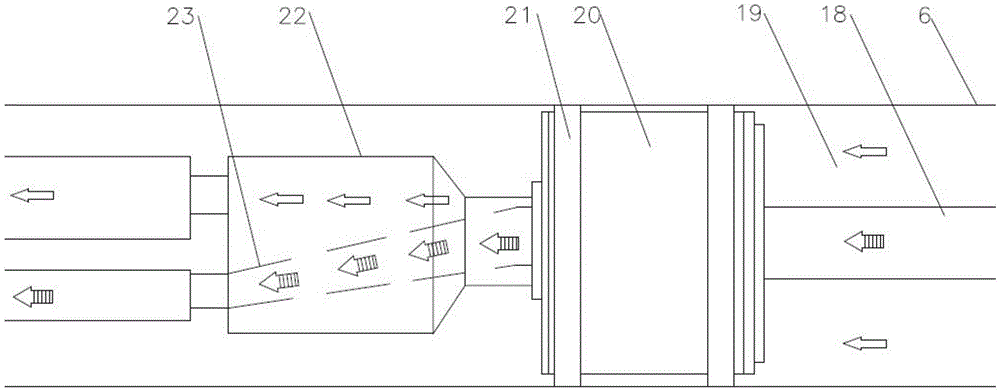

[0029] An example flow of the method of the present invention is: the natural gas hydrate on the seabed is in a stable state under the seabed environment, and when the external environment changes, the natural gas hydrate will decompose from solid to liquid and gaseous. The natural gas hydrate collected on the seabed is usually a gas-liquid mixture, and a certain amount of sediment is generally mixed in the mixture. The natural gas hydrate pipeline transportation device of the present invention separates the natural gas hydrate mixture from solid-liquid to gas underwater, and then transports the separated natural gas and water to the sea surface.

[0030] Firstly, the steady state of natural gas is changed by decompression method, the natural gas hydrate mixture containing sediment is collected and transported to the hydrocyclone, and the sediment in the mixture is removed by centrifugal force separation, and the natural gas hydrate mixed liquid to be treated is extracted from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com