Quick heating system

A heating system and rapid heating technology, applied in electric heating systems, heating systems, household heating and other directions, can solve the problems of environmental damage, inability to deal with flue gas, and slow room temperature rise, so as to avoid temperature rise and improve heat dissipation. Speed, the effect of increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

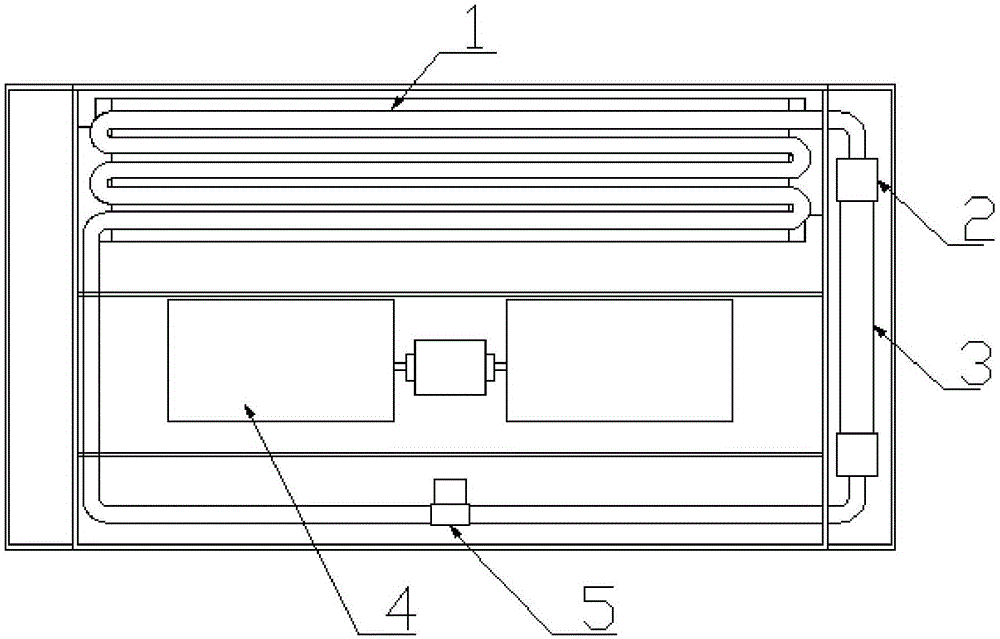

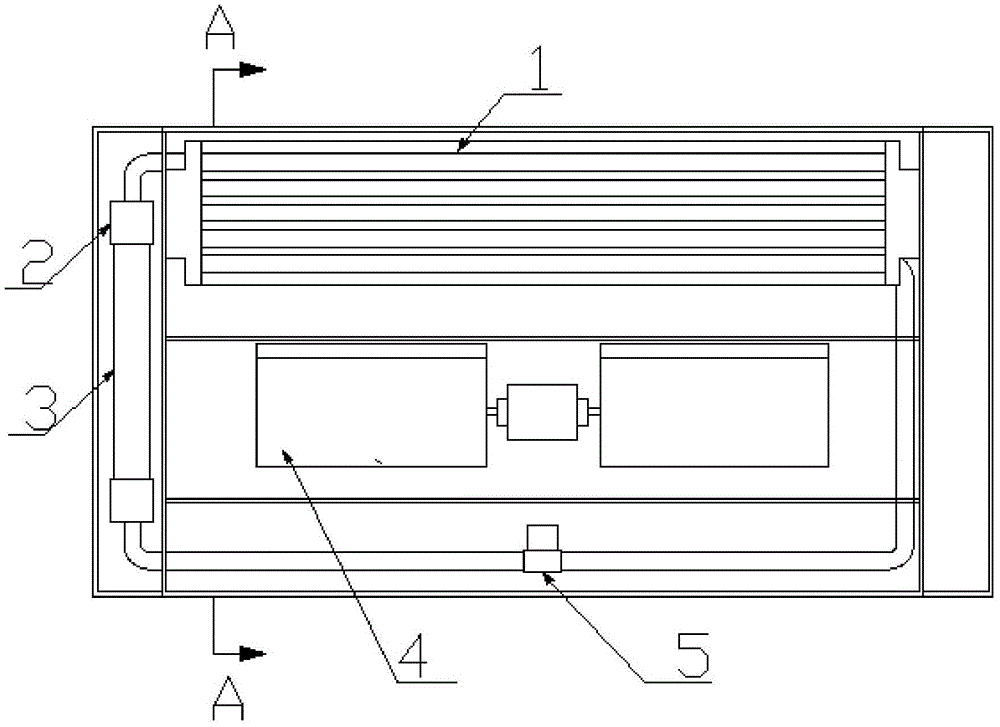

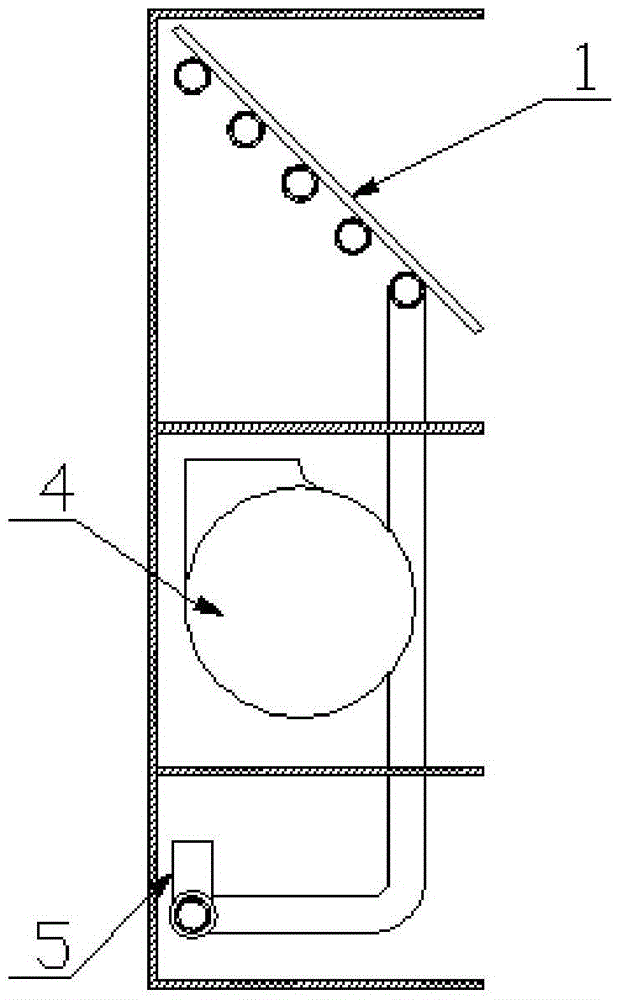

[0053] Such as Figure 1-3 As shown, the rapid heating heating system of this embodiment of the present invention includes a casing, and a heat dissipation circulation loop arranged inside the casing;

[0054] The housing is divided into three chambers horizontally, namely a heating chamber, a heat dissipation chamber and a control chamber. The heating chamber located in the middle is provided with a heat dissipation chamber, a fan chamber and a pump chamber in sequence from top to bottom; Heating device, the heating device includes at least one coated electric heating crystal tube 3 and upper and lower water collectors 2 arranged at both ends of the coated film electric heating crystal tube, the upper and lower water collectors 2 are respectively arranged There are an outlet water temperature sensor and a return water temperature sensor, the cooling fins 1 are placed horizontally in the heat dissipation chamber, the fan 4 is arranged corresponding to the cooling fins in the f...

Embodiment 2

[0057] On the basis of the above examples, if Figure 4-5 As shown, the heat dissipation cavity also includes an energy storage chamber, the energy storage chamber is arranged below the pump chamber, and the energy storage chamber is provided with a flexible accumulator 7 connected to the heat dissipation circulation circuit; the flexible energy storage chamber The device includes a rigid inner tube 9 and a flexible water bag 8 sleeved outside the rigid inner tube. A water storage cavity is arranged between the rigid inner tube 9 and the flexible water bag 8. Both ends of the flexible water bag 8 are connected to the The rigid inner tube 9 is sealed and connected, the tube wall of the rigid inner tube 9 is provided with a screen hole 10, and the inner wall of the energy storage chamber is provided with a limit switch 6 at a position corresponding to the flexible accumulator. When the water in the heat dissipation circulation loop expands, the flexible water bladder 8 expands, ...

Embodiment 3

[0061] On the basis of the above examples, if Figure 6-7 As shown, a piston accumulator can also be arranged in the accumulator chamber, and the piston accumulator includes a cylinder body 12 and a piston 13. A travel switch 14 is arranged at a position corresponding to the piston 13 in the energy storage chamber. When the water in the circulation circuit expands, the piston 13 moves to the open end of the cylinder body 12, triggers the travel switch 14, and the heating device stops heating. When the water in the heat dissipation circulation circuit is lost, the piston 13 13 moves to the end where the cylinder body 12 is connected with the circulation loop, and replenishes water in the circulation loop;

[0062] In this embodiment, a rigid cylinder body 12 and a piston 13 are used as accumulators, which are easy to install and reliable in performance. In addition, in the initial state, the piston 13 is located in the middle of the cylinder body 12. Since the water in the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com