Apparatus and method for measuring throttling effect coefficient of high-pressure complex fluid

An effect, high-pressure technology, applied in the field of devices for measuring the throttling effect coefficient of high-pressure complex fluids, which can solve the problems of difficulty in experimental measurement and increased difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

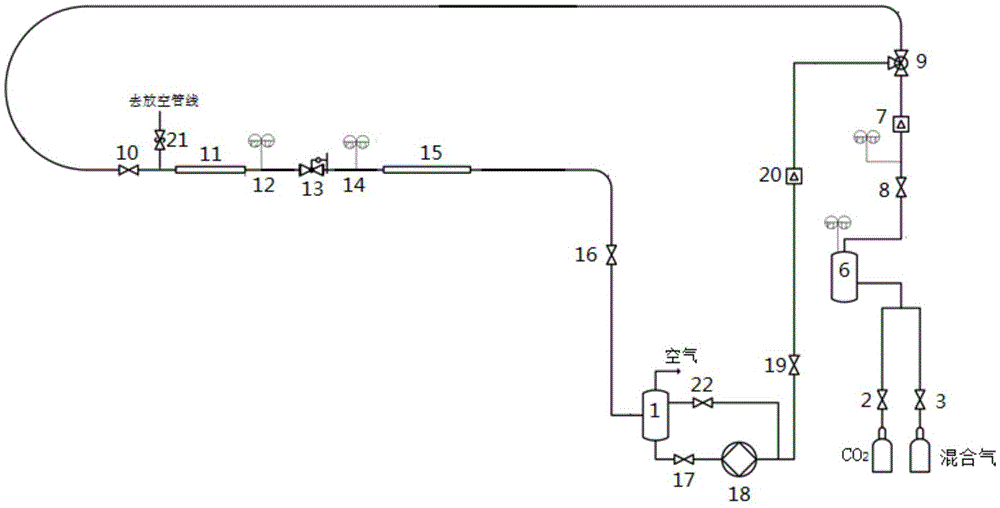

[0037] Such as figure 1 , figure 2 As shown, a device for measuring the throttling effect coefficient of high-pressure complex fluids can simulate the wellhead throttling conditions of oil and gas fields in the laboratory and measure CO 2 The temperature drop before and after the throttle valve during the wellhead throttling process of the fluid produced in the oil displacement well. The device includes an experimental loop about 20m long, with a pipe inner diameter of 26mm and a pressure bearing capacity of 10MPa. It is made of corrosion-resistant 316L stainless steel and can withstand CO 2 corrosion. The experimental device is mainly divided into six parts: gas phase system, oil-water system, mixing system, throttling and observation system, separation system, and temperature control system; details are as follows:

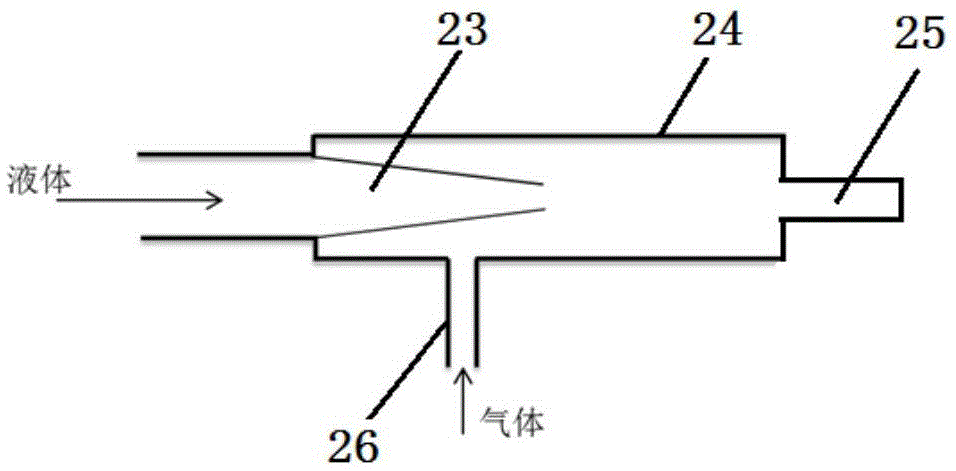

[0038] The mixing system includes a gas-liquid mixer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com