Electromagnetic ultrasonic transducer of end portion-free detection blind area

A technology for detecting blind spots and ultrasonic waves, applied in the direction of using ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, instruments, etc. Signal-to-noise ratio and other issues, achieve the effect of uniform distance, eliminate detection blind spots, increase strength and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

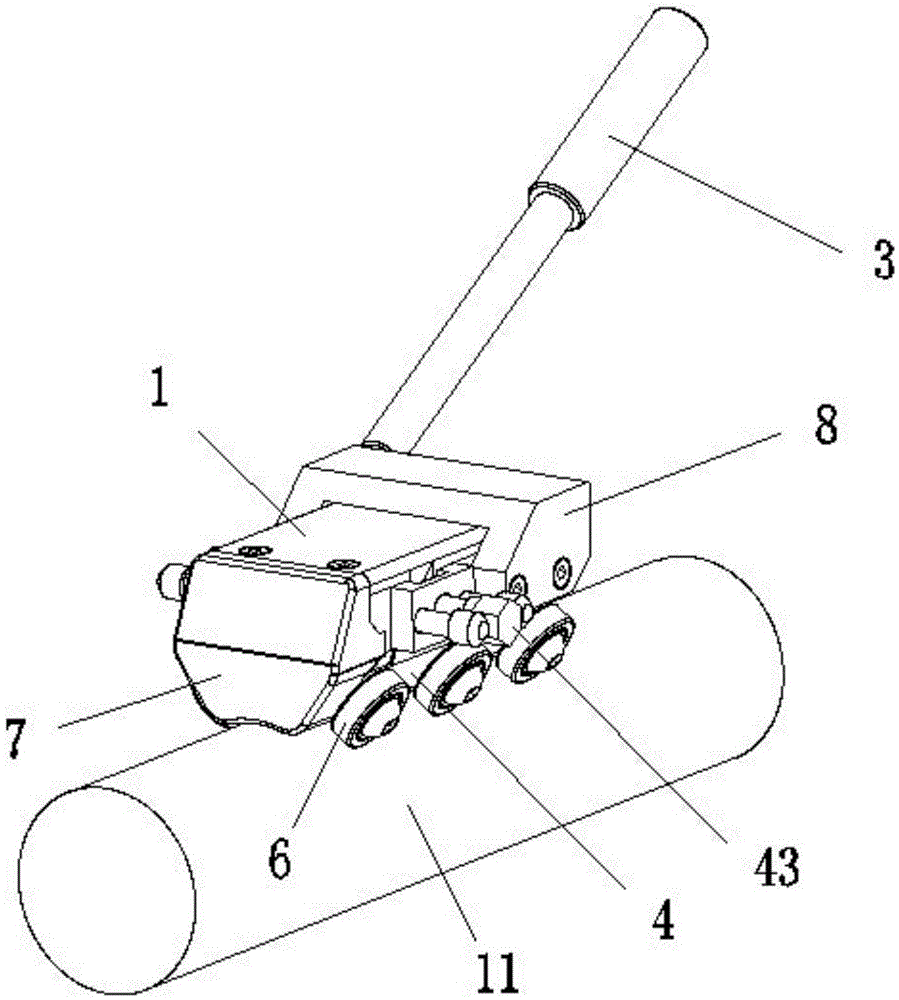

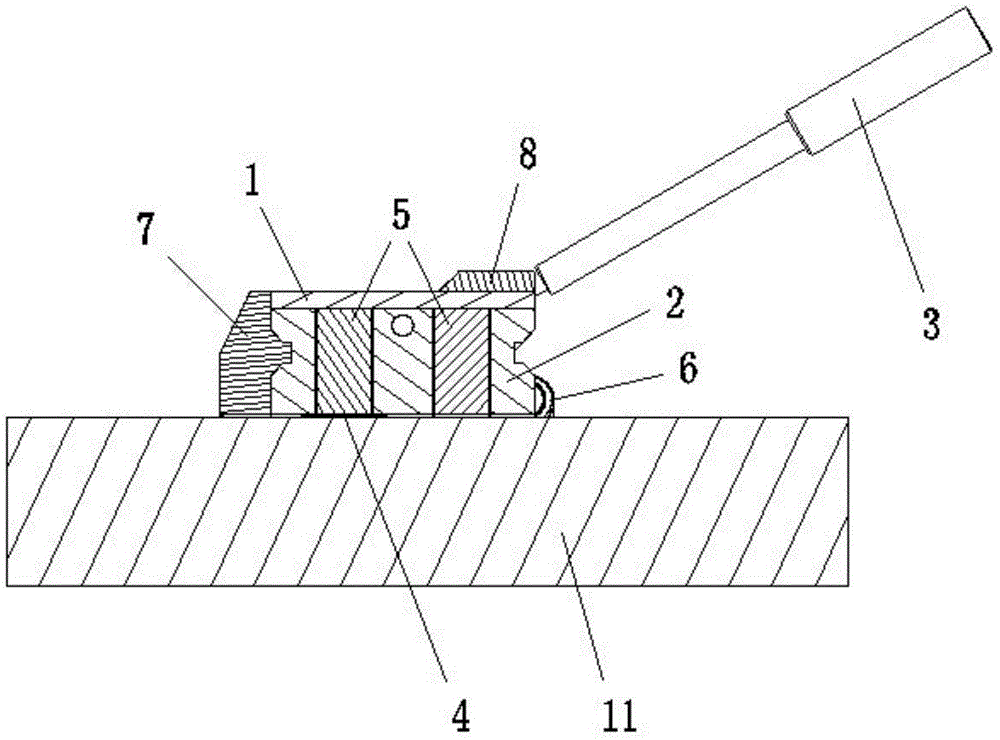

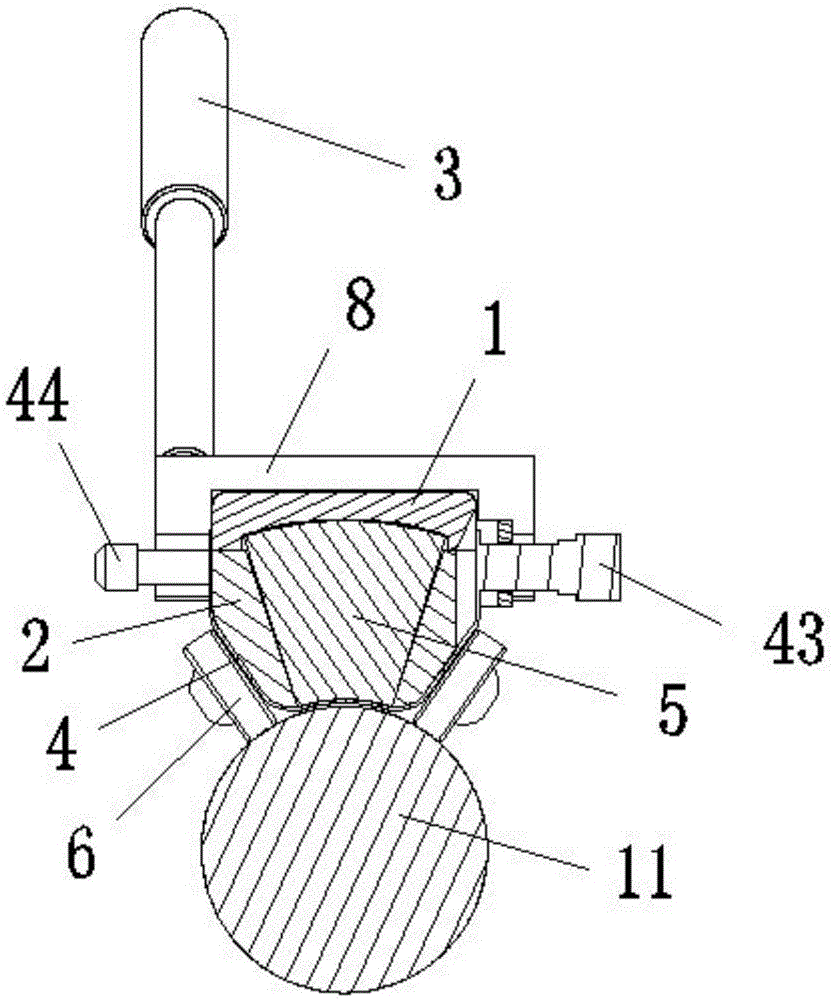

[0022] The present invention is described below in conjunction with accompanying drawing.

[0023] as attached Figure 1-4 As shown, an electromagnetic ultrasonic transducer without end detection blind zone according to the present invention includes a magnetic upper casing 1 and a non-magnetic lower casing 2, and a traction handle 3 for holding and operating; The lower casing 2 is provided with a high-frequency coil 4 and two permanent magnets 5 with the same magnetic pole direction, and a flame-retardant insulating material is filled between the permanent magnet 5 and the lower casing 2; the upper casing 1 is installed on the lower casing 2, so that two permanent magnets 5 are adsorbed on the upper casing 1 in parallel with each other; Cooperate with the lower housing 2, the rear end cover 8 clamps the upper housing 1 on the lower housing 2 at the rear side, the traction handle 3 is obliquely fixed on one side of the rear end cover 8, and the front end cover 7 has an anti-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com