Analysis method of polycyclic aromatic hydrocarbon content and application thereof

A polycyclic aromatic hydrocarbon and analysis method technology, applied in the application field of content, can solve the problems that the detection sensitivity cannot meet the needs of environmental protection rubber oil analysis, the separation and enrichment is difficult, etc., and achieves high repeatability, good repeatability, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

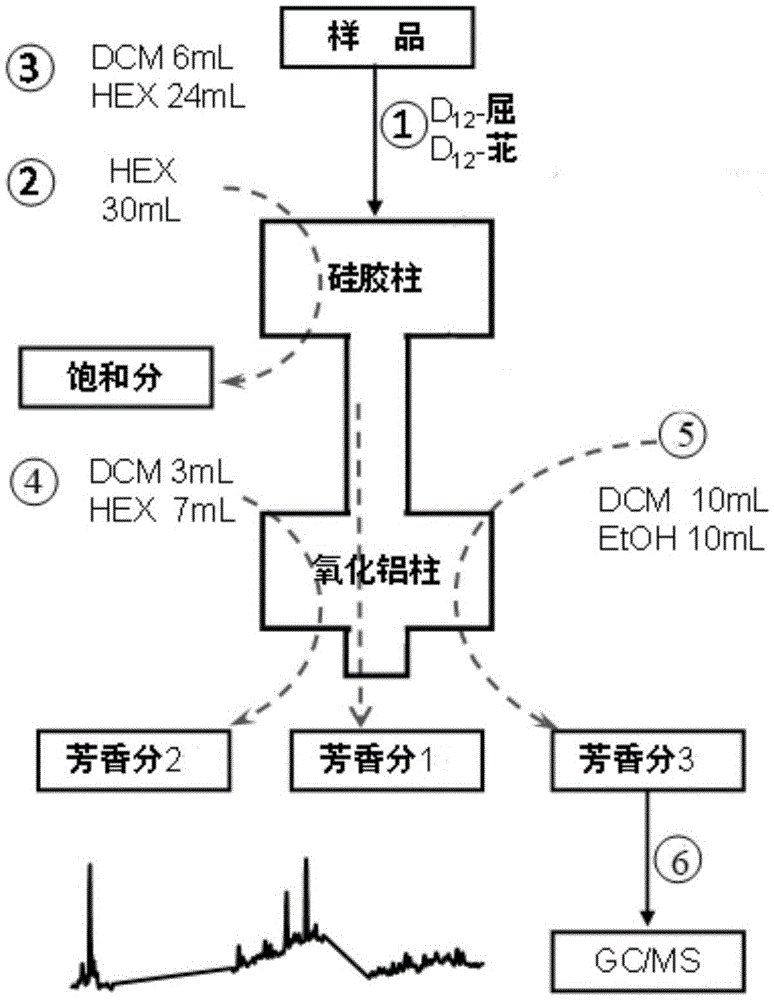

[0063] This embodiment provides a method for quantitatively analyzing polycyclic aromatic hydrocarbons in an environmentally friendly rubber filler oil with low aromatic content (China Petroleum Liaohe Petrochemical Company, naphthenic type environmentally friendly rubber filler oil), the specific steps are as follows:

[0064] First, 15 ml and 10 ml of n-hexane were respectively used to wet the solid phase extraction column (silica gel column) filled with silica gel filler and the solid phase extraction column (alumina column) filled with alumina filler.

[0065] Weigh 1 gram of sample oil into a small beaker, add 0.5 micrograms of D 12 - Perylene, D 12 - As an internal standard, dissolve the sample with 3-5 ml of n-hexane (HEX, the volume is part of the n-hexane for flushing the saturated fraction), and transfer to the top of the silica gel column. Rinse with 30 ml of n-hexane to obtain a saturated fraction.

[0066] The silica gel column and the alumina column are connect...

Embodiment 2

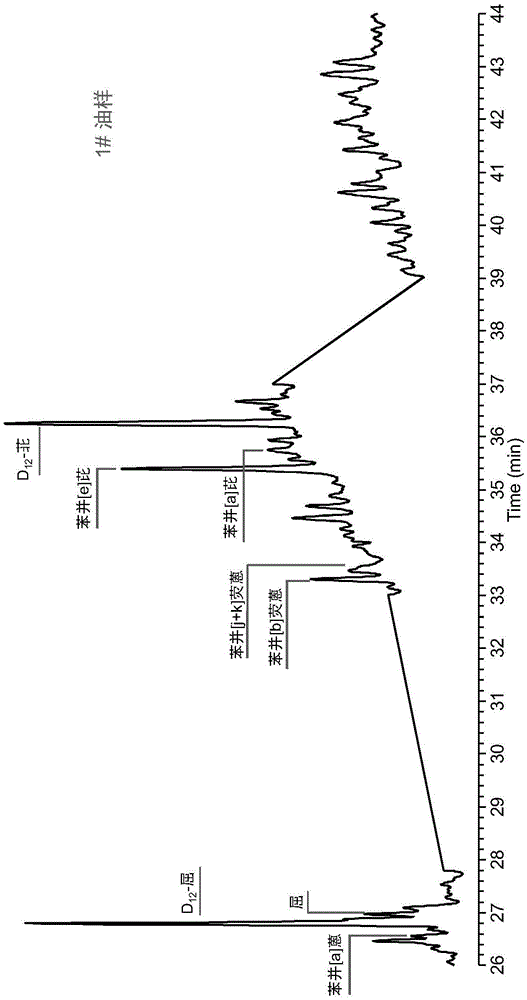

[0078] This embodiment provides a method for quantitative analysis of polycyclic aromatic hydrocarbons in high aromatic content environment-friendly rubber filler oil (China Petroleum Liaohe Petrochemical Company, aromatic hydrocarbon type environment-friendly rubber filler oil, denoted as 1# oil sample), the specific steps are as follows:

[0079] First, 15 mL and 10 mL of n-hexane were used to wet the silica gel column and the alumina column, respectively.

[0080] Weigh 200 mg of sample oil into a small beaker, add 0.5 μg of D 12 - Perylene, D 12 -Ji as an internal standard, dissolve the sample with 3-5 milliliters of n-hexane (this volume is a part of the n-hexane for flushing the saturated fraction), and transfer to the top of the silica gel column, rinse with 30 milliliters of n-hexane to obtain the saturated fraction.

[0081] The silica gel column and the alumina column are connected in series, with the silica gel column at the top and the alumina column at the bottom...

Embodiment 3

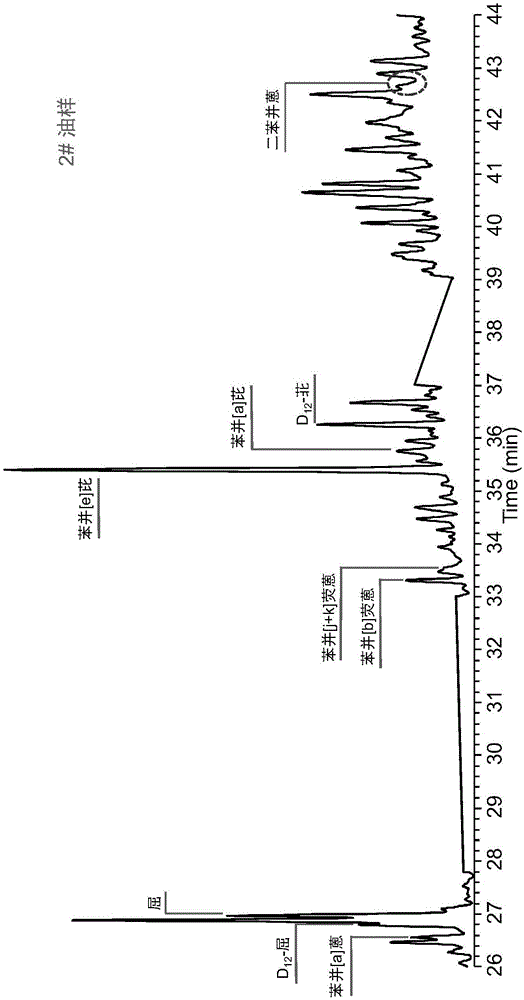

[0090]This embodiment provides a method for quantitative analysis of polycyclic aromatic hydrocarbons in the production of environmentally friendly rubber extension oil raw material oil (China Petroleum Liaohe Petrochemical Branch, denoted as 2# oil sample), and its specific steps are as follows:

[0091] First, 15 mL and 10 mL of n-hexane were used to wet the silica gel column and the alumina column, respectively.

[0092] Weigh 20 mg of sample oil into a small beaker, add 2 micrograms of D 12 - Perylene, D 12 - Make the internal standard, dissolve the sample with 3-5 ml of n-hexane (the volume is part of the n-hexane for washing the saturated fraction), and transfer to the top of the silica gel column, rinse with 30 ml of n-hexane to obtain the saturated fraction.

[0093] The silica gel column and the alumina column are connected in series, with the silica gel column at the top and the alumina column at the bottom. Prepare 30 ml of a mixed solution of dichloromethane and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com