Low-attenuation, high-power and high-temperature coaxial radio frequency cable and production technology

A coaxial radio frequency cable and its preparation technology are applied in the occasions where the indoor coverage requires small attenuation, the signal transmission is connected to the feeder, and the power is high. It can solve the problems of cable heating, low power use, and loss of insulation of the cable insulation layer. The effect of high frequency, increased product application occasions, and improved shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

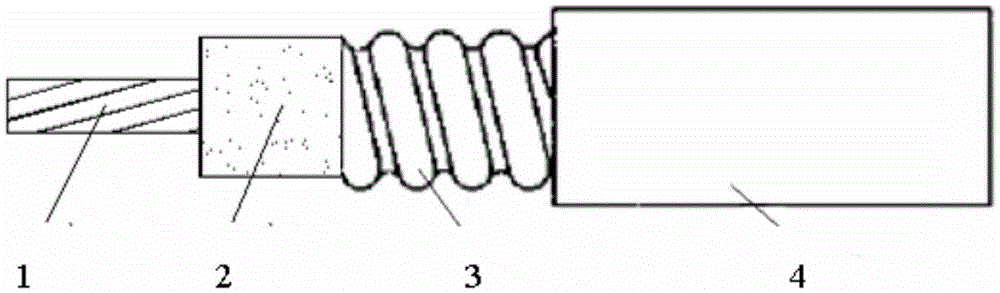

[0019] like figure 1 The shown low-attenuation high-power high-temperature coaxial radio frequency cable includes an inner conductor layer 1, an insulating layer 2, a shielding layer 3 and a sheath layer 4, the inner conductor layer 1 is provided with an insulating layer 2, and the insulating layer A shielding layer 3 is provided on the outside of the layer 2, and a sheath layer 4 is provided on the outside of the shielding layer 3.

[0020] Further, the inner conductor layer 1 adopts silver-plated copper wire or ductile copper wire, and the diameter of the conductor is 2-3mm.

[0021] Further, the insulating layer 2 is made of low-density polytetrafluoroethylene, the thickness of the insulating layer is 2-2.5mm, and the concentricity of the insulating layer is over 92%.

[0022] Further, the shielding layer 3 is made of corrugated copper pipe, the width of the copper strip welded into the copper pipe is 21-23mm, and the corrugation pitch is 3.5-3.9mm.

[0023] Further, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com