LED chip electrode structure that can improve lateral current spreading and has double reflective surfaces

A LED chip and electrode structure technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of poor reflection effect, low reflectivity, and poor light extraction effect, so as to increase light output efficiency and promote Diffusion, increase the effect of lateral diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

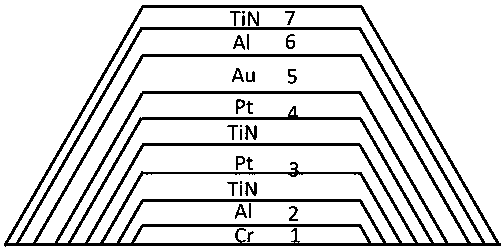

[0021] Such as figure 1 As shown, the present invention includes a layer of Cr layer 1, a first layer of Al 2, a first pair of TiN / Pt layers 3, a second pair of TiN / Pt layers 4, an Au layer 5, The second Al layer 6 and the TiN outer layer 7 constitute the electrode extension bar with trapezoidal structure.

[0022] Wherein, the thickness of the Cr layer is 10-50 angstroms.

[0023] The thickness of the first Al layer is 1000˜5000 angstroms.

[0024] In each pair of TiN / Pt layers, the thickness of TiN is 500-2000 angstroms, and the thickness of Pt is 500-2000 angstroms.

[0025] The thickness of the Au layer is 5000-20000 angstroms.

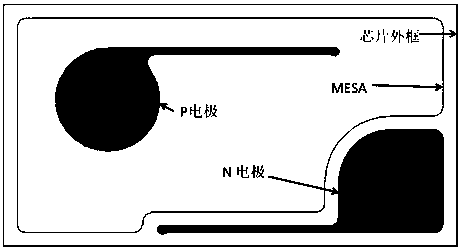

[0026] The electrode structure of the present invention is applied to conventional parallel electrode structure design such as figure 2 shown.

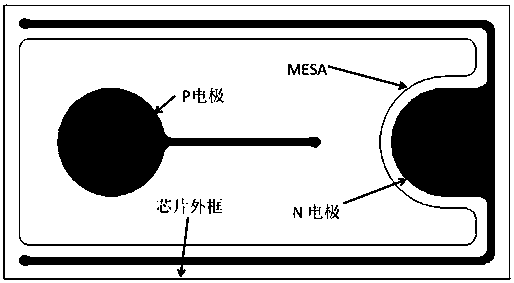

[0027] The electrode structure of the present invention is applied to the design under the situation that the MESA is wrapped by the N electrode extension strip, such as image 3 shown. Its double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com