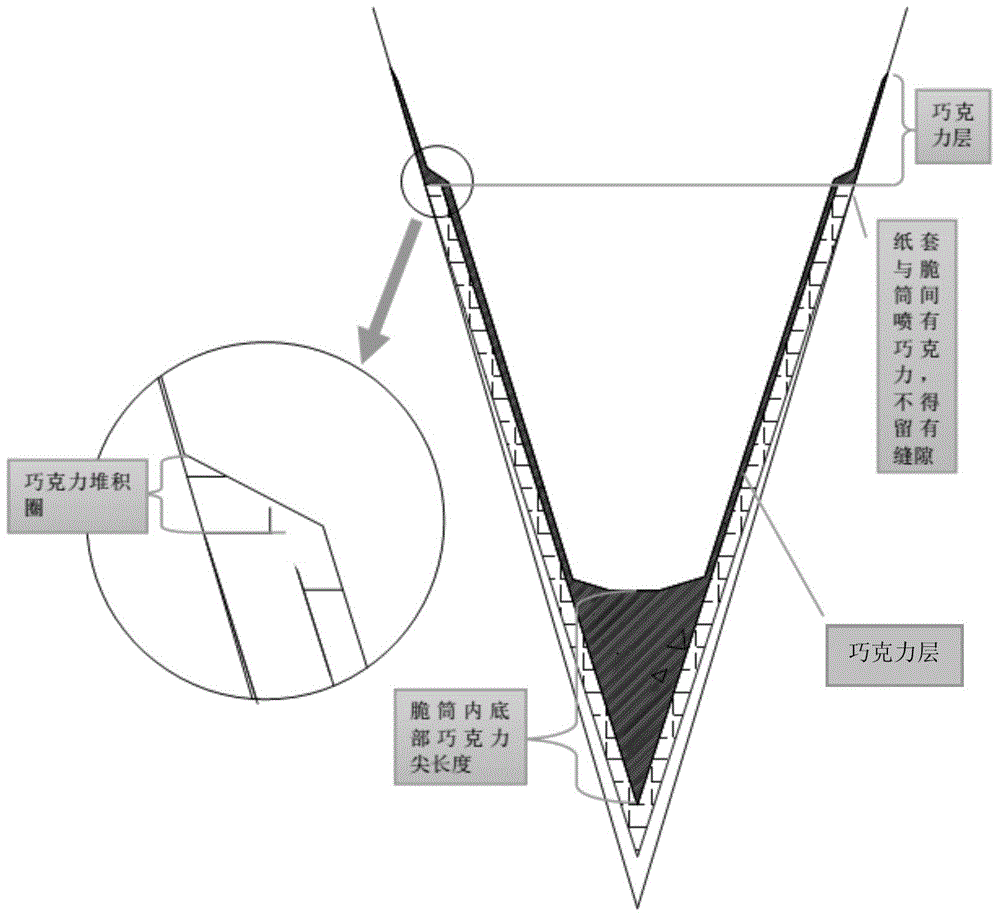

Chocolate composition and crisp cylinder ice cream sprayed with chocolate composition

A technology of chocolate and composition, applied in the field of crispy ice cream, which can solve the problems of poor moisture-proof and water-proof ability of crispy ice-cream, and achieve the effect of good viscosity and fluidity, good water-proof and moisture-proof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a chocolate composition, in terms of weight percentage, its raw material composition comprises: 43.7% of white granulated sugar, 10% of cocoa powder, 23% of palm kernel oil with a melting point of 22°C, and 22.5% of palm oil with a melting point of 41°C , 0.7% of phospholipid, 0.1% of vanillin; by weight percentage, the total fat content of the chocolate composition is 45.5%.

[0061] The chocolate composition is prepared by the following method:

[0062] Raw material pretreatment: Spray white granulated sugar into white granulated sugar powder with a powder sprayer so that the white granulated sugar can pass through an 80-mesh sieve, chop solid oils such as palm kernel oil, and then heat and melt the palm kernel oil (palm kernel oil) Heating temperature ≤ 50°C), palm oil for standby;

[0063] Feeding after weighing: Weigh the raw materials according to the ratio, then start the main engine, put palm kernel oil, palm oil, cocoa powder and white...

Embodiment 2

[0075] This embodiment provides a chocolate composition, in terms of weight percentage, its raw material composition comprises: 40% of white granulated sugar, 11% of cocoa powder, 23.4% of palm kernel oil with a melting point of 22°C, and 25% of palm oil with a melting point of 41°C , 0.5% phospholipid, 0.1% vanillin; by weight percentage, the total fat content of the chocolate composition is 49%.

[0076] The preparation method of this chocolate composition is the same as that in Example 1.

[0077] This embodiment also provides a crispy ice cream cone, in which the above-mentioned chocolate composition is sprayed.

[0078] The chocolate composition is sprayed into the ice cream cone by the following method:

[0079] Filter the chocolate composition through an 80-mesh sieve;

[0080] Clean the chocolate heat preservation tank, then wipe the residual water with a clean and sterile dry cloth, turn on the electric heating device of the chocolate heat preservation tank, so that...

Embodiment 3

[0084] This embodiment provides a chocolate composition, in terms of weight percentage, its raw material composition comprises: 40% of white granulated sugar, 11% of cocoa powder, 28.2% of palm kernel oil with a melting point of 22°C, and 20% of palm oil with a melting point of 41°C , 0.7% phospholipid, 0.1% vanillin; by weight percentage, the total fat content of the chocolate composition is 49%.

[0085] The preparation method of this chocolate composition is the same as that in Example 1.

[0086] This embodiment also provides a crispy ice cream cone, in which the above-mentioned chocolate composition is sprayed.

[0087] The chocolate composition is sprayed into the ice cream cone by the following method:

[0088] Filter the chocolate composition through an 80-mesh sieve;

[0089] Clean the chocolate heat preservation tank, then wipe the residual water with a clean and sterile dry cloth, turn on the electric heating device of the chocolate heat preservation tank, so that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com