Cleaning machine and cleaning method for renewable cartridge

A washing machine and ink cartridge technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve cleaning problems, achieve high efficiency, improve product qualification rate, and improve cleaning cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

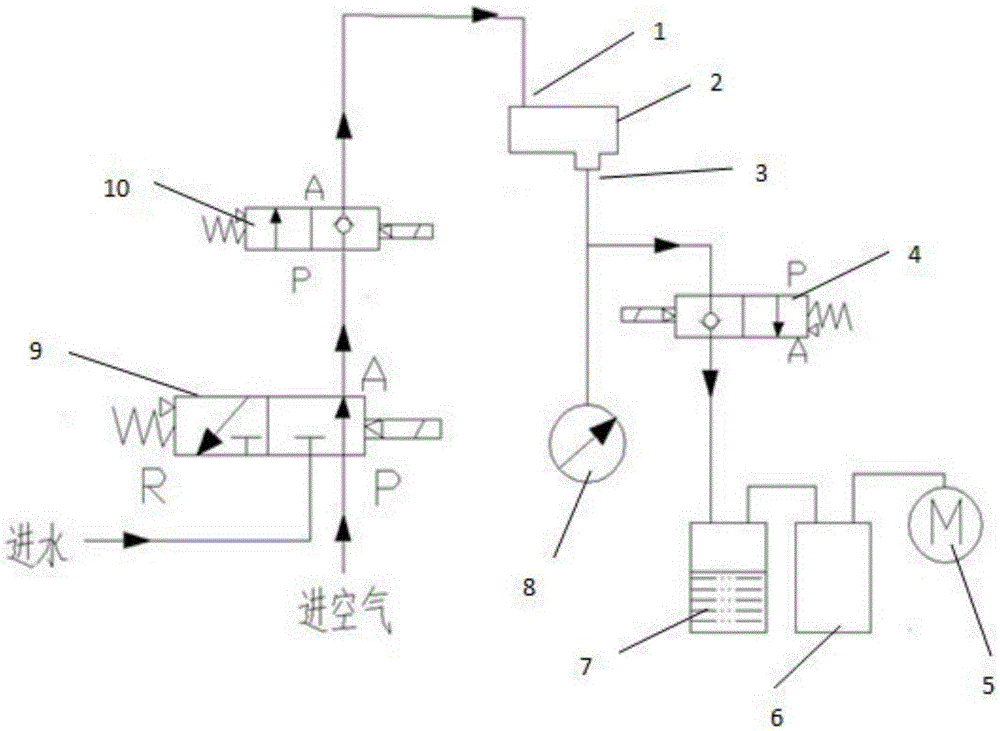

Method used

Image

Examples

Embodiment A

[0050] The cleaning method includes the following steps:

[0051]Step 1. Connect the first interface of the washing machine to the ink filling port of the ink cartridge, and connect the second interface to the ink outlet of the ink cartridge to realize the connection between the washing machine and the ink cartridge. The solenoid valve is opened, the two-position direct solenoid valve of the flushing device is closed, and the negative pressure evacuates the air inside the ink cartridge;

[0052] Step 2. Close the two-position straight-through solenoid valve of the flushing device through the controller, observe the reading of the negative pressure gauge, the reading of the negative pressure gauge becomes smaller, and then check whether there is air leakage in the connecting part, and find that the first interface is connected to the ink filling port of the ink cartridge If it is not tight, close the two-position straight-through solenoid valve of the flushing device, wrap the ...

Embodiment B

[0057] The cleaning method includes the following steps:

[0058] Step 1. Connect the cleaning machine to the ink cartridge, open the two-position direct solenoid valve of the flushing device through the controller, close the two-position direct solenoid valve of the flushing device, and evacuate the air inside the ink cartridge with negative pressure;

[0059] Step 2. Close the two-position straight-through solenoid valve of the washing device through the controller, observe the reading of the negative pressure gauge for 5 seconds, and the reading of the negative pressure gauge remains unchanged;

[0060] Step 3, through the controller, simultaneously open the water inlets of the two-position direct solenoid valve of the flushing device, the two-position direct solenoid valve of the flushing device, and the two-position three-way solenoid valve;

[0061] Step 4. Control the switching of the water inlet and the air inlet of the two-position three-way solenoid valve through the...

Embodiment C

[0064] The cleaning method includes the following steps:

[0065] Step 1. Connect the cleaning machine to the ink cartridge, open the two-position direct solenoid valve of the flushing device through the controller, close the two-position direct solenoid valve of the flushing device, and evacuate the air inside the ink cartridge with negative pressure;

[0066] Step 2. Close the two-position direct solenoid valve of the washing device through the controller, and observe the reading of the negative pressure gauge. The reading of the negative pressure gauge becomes smaller. After testing that there is no air leakage in the connection part of the equipment, close the two-position direct electromagnetic valve of the washing device. valve, then remove the ink cartridge, and connect the next ink cartridge to the cleaning machine; open the two-position direct solenoid valve of the flushing device through the controller, close the two-position direct solenoid valve of the flushing devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com